Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

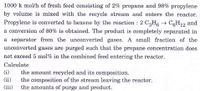

Transcribed Image Text:1000 k mol/h of fresh feed consisting of 2% propane and 98% propylene

by volume is mixed with the recycle stream and enters the reactor.

Propylene is converted to hexene by the reaction : 2 C3H6 → C6H12 and

a conversion of 80% is obtained. The product is completely separated in

a separator from the unconverted gases. A small fraction of the

unconverted gases are purged such that the propane concentration does

not exceed 5 mol% in the combined feed entering the reactor.

Calculate

the amount recycled and its composition.

the composition of the stream leaving the reactor.

the amounts of purge and product.

(i)

(ii)

(iii)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 5 steps with 10 images

Knowledge Booster

Similar questions

- Q2. Consider a fuel which is an equimolar mixture (1 mole each) of propane (C3Hs) and methane (CH4). (a) Write the complete stoichiometric combustion reaction for this fuel with air (b) Determine the stoichiometric A/F ratio of this fuel (C) Estimate the maximum flame temperature using average specific heat cp at 1200 K. Assume the boiler using this fuel operates at 1 atm and the reactants enter at 298 K. AH(C3H8) -103,847 kJ/kmol. AHCHA)-74,831 kJ/kmol AH (H20) =-241,847 kJ/kmol, AH'r(co2) - 393,546 kJ/kmol, CP120-43.87 kJ/kmol.K Cpco2 = 56.20 kJ/kmol.K. Cps2 = 33.71 kJ/kmol.Karrow_forwardOne of the ways that benzene is produced on a large scale is the hydrodealkylation of toluene. C,H,CH; + H, C,H, + CH4 A stream of toluene is mixed with a recycle stream and enters a reactor along with a stream of pure hydrogen. The reaction products at 550 °C enter a condenser, where they are cooled to 41.0 °C. A vapor stream containing Y5CH, = 0.600 mol CH,/mol leaves the process, and a liquid stream containing x66 = 0.810 mol benzene/mol and x6 = 0.190 mol toluene/mol enters a distillation column. The distillate of the column leaves the process at n7 = 668.0 mol/h and contains y7h = 0.9000 mol benzene/mol and y7 = 0.1000 mol toluene/mol. The bottoms of the column contains X8b = 0.250 mol benzene/mol and xgt = 0.750 mol toluene/mol and is recycled back to the fresh feed. Hydrogen is fed into the process at ni = 1183 mol H,/h. This process is carried out at 760 mmHg. A n, mol/h mol H/mol YSH2 YSCH, mol CH_/mol Ysh mol b/mol Ys mol t/mol n̟ mol/h n, mol/h Condenser Улн, тol H/mol Усн,…arrow_forward3. Kindly answer this and show your solution.arrow_forward

- Aniline is produced by the hydrogenation of nitrobenzene. A small amount of cyclohexylamine is produced as a by-product. Nitrobenzene is fed to the reactor as a vapor with three times the required stoichiometric amount of hydrogen. The conversion of nitrobenzene to the products is 96% and the selectivity to aniline is 85%. Unreacted hydrogen is separated from the reaction products and recycled to the reactor. From the recycle line it is purged to keep the inerts in the recycle stream below 5%. The fresh hydrogen that is fed is 99.5% pure and the rest is inert. Calculate the adiabatic outlet temperature of the reaction products and indicate the relationship with respect to the reference temperature (298.15) (in K):arrow_forwardCalculate the amount of heat required to pass through each section of the graph. Here are the heat capacities and phase change enthalpies of water. ΔHfus or enthalpy of fusion or the first phase change from solid to liquid ΔHfus = 6.01kJ/mol ΔHvap or enthalpy of vaporization or the second phase change from liquid to gas ΔHvap = 40.7kJ/mol cliquid water or specific heat of water in the liquid phase cliquid water = 4.184J/g℃ cice or specific heat of water in the solid phase cice = 2.108J/g℃ cwater vapor or the specific heat of water in the gas phase cwater vapor= 1.996J/g℃arrow_forwardMaterial and energy balancearrow_forward

- Professor Modyn's steady state flow reactor is now fed acetylene (C₂H₂) at 2.000 mol/s. The acetylene is combusted with 45.00% excess dry air to form CO2 and H2O. Limitations within the reactor only allow 82.00% of the acetylene to react. Both the acetylene and air enter the reactor at 25 °C, and the products leave the reactor at 1027.00 °C. Potentially useful properties are listed in the following table. Species Ahr(298 K), kJ/mol Cp, kJ/kmol-K 02 0 3.5R N₂ 0 3.5R C₂H₂ -226.73 4R CO2 H₂O(g) -393.5 4R -241.82 5R Determine the exiting flow rate of 02. 5.945 exiting flow rate: Determine the heat interaction term. -2085.37 mol/s heat interaction term: kWarrow_forwardA fuel is prepared by mixing 4 moles of argon (Ar, inert) with 12 moles of ethane (C2H6) and 6moles of propane (C3H8) and undergoes complete combustion in air according to the followingreactions:C2H6 + 7/2 O2 reacts to form 2 CO2 + 3 H2OC3H8 + 5 O2 reacts to form 3 CO2 + 4 H2OAir may be considered as 21 mol% oxygen (O2) and 79 mol% Nitrogen (N2).The average molecular mass of a mixture can be calculated as Maverage = Σ xi Mi where xi and Mi are molefraction and molecular mass of component i. Atomic masses: C = 12; O = 16; H = 1; N = 14; Ar = 40.Calculate:a. the theoretical air required to burn the fuel (in kg air per kg fuel) b. the mole fraction of CO2 on a wet basis in the flue gas if the fuel is burned with 30% excess air,assuming complete combustionarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The