Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

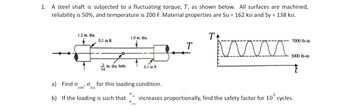

Transcribed Image Text:1. A steel shaft is subjected to a fluctuating torque, T, as shown below. All surfaces are machined,

reliability is 50%, and temperature is 200 F. Material properties are Su = 162 ksi and Sy = 138 ksi.

1.2 in. dia.

1.0 in. dia.

Ꭲ

0.1 in R

T

プ

1 in. dia, hole

0.1 in R

a) Find o

em'

σ for this loading condition.

ea

b) If the loading is such that

7000 lb-in.

3000 lb-in.

0

increases proportionally, find the safety factor for 10° cycles.

σ

em

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Similar questions

- Please answer part a and barrow_forwardB).shear stress caused by T C).APply miaximum-Distortion-energy Theory and calculate Mises equivalent stress. Enter your answer in MPa to 2 decimal places. D). determine factor of safety n (upto 2 decimal places)arrow_forwardCan someone please help me to solve number 1 and 2 showing all work thank you!arrow_forward

- Please don't provide handwritten solution...arrow_forwardThe rotating shaft in the given figure is machined from AISI 1020 CD steel. It is subjected to a force of F = 6 kN . Find the minimum factor of safety for fatigue based on infinite life. Be sure to check for yielding. 25 D. ] -35 D. 3 R. Dimensions in millimeters 500 -175- -50 D. 25 D. 20 20 20 180 280 20 What is the factor of safety against fatigue at infinite life? (Round the final answer to three decimal places.) The value of the factor of safety isarrow_forwardQ.3 In a bushmandrel system, a bush was turned on a mandrel. The mandrel diameter in millimeter is 400.00 -0.05 and bore diameter of bush is 40+0.06 The -0.010 maximum eccentricity of the bush in mm will be A 0.025 0.045 C 0.055 D 0.065arrow_forward

- Multi part question The rotating shaft shown is subjected to a constant force. Shaft material is AISI 1020 cold drawn steel. The shaft was turned on a lathe using standard carbide tooling. No heat treatment of the shaft was performed. Assume 99% reliability based on material property data. Shaft dimensions are shown in the illustration below. All dimensions in mm. External force is 3.927 kN. Calculate the highest alternating stress in the shaft, in MPa. -20 -35 D. 180- -500 3R. -280- -175- -50 D. 25 D.arrow_forwardA.1.4) Locational interference fits Basic hole system. Limits are in thousandths of an Limits for hole and shaft are applied algebraically to the basic size to obtain Nominal Size Range Inches To Class LN1 Standard Limits Shaft +0.45 +0.25 +0.5 Class LN2 Standard Limits Shaft +0.65 +04 +0.8 Class LN3 Standard Limits Shaft +0.75 +05 +0.9 Hole +0.25 Over Hole 0.4 Hole -0.12 *0.4 0.12 -0.24 +0.3 +0.5 +0.5 +0.3 +0.65 +0.4 +0.8 +0.5 +06 +1.2 0.8 0.24 -0.40 +0.4 +0.6 +1.0 +0.6 +0.4 +0.6 +1.1 0.40 - 0.71 +0.7 +0.7 +14 +0.4 +0.7 +1.3 +0.8 +1.6 +1.0 +10 +1.7 12 2.0 +1.4 +23 +1.6 +2.9 +20 +3.5 +25 0.71 1.19 +0.5 +1.0 +0.8 +0.8 +0.5 1,19 - 1,97 +0.6 +1.1 +1.0 +1.0 +0.6 +1.3 +0.8 +1.6 +1.0 +1.9 +1.2 +22 - 3.15 +1.2 +2.1 +1.2 1.97 +0.7 +14 +1.4 +2.5 +1.6 3.15 -4.73 +0.9 +1.4 +1.6 +2.8 +1.8 +3.2 +2.0 +3.4 +22 +3.9 25 +44 +2.8 - 7.09 +1.0 +1.6 4.73 +1.8 +42 +1.8 +30 +47 7.09 -9.85 +1.2 +1.4 +2.3 +2.0 +2.0 +3.5 +5.9 +45 *6.6 +5.0 +1.2 9.85 - 12.41 +1.4 22 +22 +2.6 +1.6 +2.8 +1.4 12.41 - 15.75 25 +2.5…arrow_forwardPlease answer all partsarrow_forward

- What force is necessary to punch a 30 mm hole in 12.5 mm thick plate if ultimate shear stress is 410 Mpa? A. 480 KN B. 481 KN C. 482 KN D. 483 KN Please solve the Problem elaborately and Refer Machine Elements and Stresses Equations from the figures or use other shortcut Methods you have or you may Solve both or in more different methods the better ?. Your solution will be use as reference for my Future Board Exam preparation/review/study. Thank you so much dear your work will be appreciated much and rated excellently.arrow_forwardA 2.5 inches shaft is subjected to 3 KN.m torque. Find the stress developed. A. 48.62 MPaB. 52.75 MPa C. 59.67 MPa D. 38.64 Mpa Please solve the Problem elaborately and Refer Machine Elements and Stresses Equations from the figures or use other shortcut Methods you have or you may Solve both or in more different methods the better ?. Your solution will be use as reference for my Future Board Exam preparation/review/study. Thank you so much dear your work will be appreciated much and rated excellently.arrow_forward7) The washing machine with a mass of 19 kg and a rotational imbalance of 0.45 N kg.m is placed on an insulator with a hardness of 41 * 105 and a depreciation m ratio of 0.08. A) Under what operating speed range is the transmission force to the base less than 3000N? B) Get the range of motion of the washing machine for the minimum and maximum speed obtained in section A.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY