Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN: 9781305387102

Author: Kreith, Frank; Manglik, Raj M.

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 10, Problem 10.6P

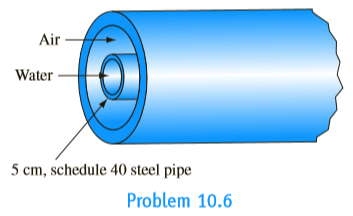

Mot water is used to heat air in a double-pipe heat exchanger as shown in the following sketch. If the

heat transfer coefficients on the water side and on the air side are

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

EXAMPLE 3

Consider the heat exchanger

finned-tube, cross-flow heat exchanger with a gas-side overall

heat transfer coefficient and area of 100 W/m² · K and 40 m²,

respectively. The water flow rate and inlet temperature remain at

1 kg/s and 35C. However, a change in operating conditions for

the hot gas generator causes the gases to now enter the heat

exchanger with a flow rate of 1.5 kg/s and a temperature of

250C. What is the rate of heat transfer by the exchanger, and

what are the gas and water outlet temperatures?

that is, a

1² .

Blowtorch is used to connect the two pipes together. Length of the pipe

section shown is 150 cm with an inner diameter of 85 cm. The thickness of

the pipe wall is 4 mm. The conductivity of the pipe section is 167 Wim^2K.

Environment has a temperature of 30 C and convective heat transfer

coefficient of 28 WI(mC), find the required heat transfer to join the pipe

sections at 220 C? HINT: Assume that the welding section is the base

plate and the pipe is 1D extended surface (fin) symmetric about the torch

melting line. Heat transfer happens by conduction along the pipe

thíckness in horizontal direction and by convection to the environment.

Length

thickness

Torch melting line

200 W

275 W

none

314 W

453 W

A cross flow plate fin compact heat exchanger is to be used for this heat recovery application.

We wish to select a heat exchanger which will yield ε = 0.75, using stainless steel fin materials. Calculate the UA required to obtain ε = 0.75. Calculate UA by ε-NTU methods and state why the LMTD method is difficult to use. For the ε -NTU methods, first use the graphical method and then the equation.

Chapter 10 Solutions

Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

Ch. 10 -

10.1 In a heat exchanger, as shown in the...Ch. 10 - Prob. 10.2PCh. 10 -

10.3 A light oil flows through a copper tube of...Ch. 10 - Prob. 10.4PCh. 10 - Water flowing in a long, aluminum lube is to be...Ch. 10 - Mot water is used to heat air in a double-pipe...Ch. 10 - Prob. 10.7PCh. 10 -

10.8 The heat transfer coefficient of a copper...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Determine the rate of heat transfer per meter length to a light oil flowing through a 2.5-cm-ID, 60-cm-long copper tube at a velocity of 0.03 m/s. The oil enters the tube at 16C, and the tube is heated by steam condensing on its outer surface at atmospheric pressure with a heat transfer coefficient of 11.3 kW/m K. The properties of the oil at various temperatures are listed in the following table: Temperature, T(C) 15 30 40 65 100 (kg/m3) 912 912 896 880 864 c(kJ/kgK) 1.80 1.84 1.925 2.0 2.135 k(W/mK) 0.133 0.133 0.131 0.129 0.128 (kg/ms) 0.089 0.0414 0.023 0.00786 0.0033 Pr 1204 573 338 122 55arrow_forward10.1 In a heat exchanger, as shown in the accompanying figure, air flows over brass tubes of 1.8-cm 1D and 2.1-cm OD containing steam. The convection heat transfer coefficients on the air and steam sides of the tubes are , respectively. Calculate the overall heal transfer coefficient for the heal exchanger (a) based on the inner tube area and (b) based on the outer tube area.arrow_forward3.14 A thin-wall cylindrical vessel (1 m in diameter) is filled to a depth of 1.2 m with water at an initial temperature of 15°C. The water is well stirred by a mechanical agitator. Estimate the time required to heat the water to 50°C if the tank is suddenly immersed in oil at 105°C. The overall heat transfer coefficient between the oil and the water is , and the effective heat transfer surface is .arrow_forward

- A refrigerant 22 condenser has four water passes and a total of 60 copper tubes that are 14 mm ID and have 2 mm wall thickness. The conductivity of copper is 3 90 W/m • K. The outside of the tubes is finned so that the ratio of outside to inside area is 1.7. The cooling-water flow through the condenser tubes is 3.8 L/s (a) Calculate the water-side coefficient if the water is at an average temperature of 30°C, at which temperature k = 0.614 W/m • K, p = 996 kg/m3 , andµ= 0.000803 Pa• s (b) Using a mean condensing coefficient of 1420 W/m2 • K, calculate the overall heat-transfer coefficient based on the condensing area.arrow_forwardA heat recovery device involves transferring energy from the hot flue gases passing through an annular region to pressurized water flowing through the inner tube of the annulus. The inner tube has inner and outer diameters of 24 and 30 mm and is connected by 8 struts to an insulated outer tube of 40-mm diameter. Each strut is 3 mm thick and is integrally fabricated with the inner tube from carbon steel (k = 50W/m-K). E1 = 3 mm D. Water Gas Consider conditions for which water at 300 K flows through the inner tube at 0.161 kg/s while flue gases at 800 K flow through the annulus, maintaining a convection coefficient of 100 W/m2-K on both the struts and the outer surface of the inner tube. What is the rate of heat transfer per unit length of tube from gas to the water? Use the Dittus-Boelter equation to obtain the water-side convection coefficient. Determine the rate of heat transfer per unit length of tube from gas to the water, in W/m. i W/m Physical Properties Mathematical Functionsarrow_forwardBlowtorch is used to connect the two pipes together. Length of the pipe section shown is 150 cm with an inner diameter of 85 cm. The thickness of the pipe wall is 4 mm. The conductivity of the pipe section is 167 W/m^2K. Environment has a temperature of 30 C and convective heat transfer coefficient of 28 WI(mC), find the required heat transfer to join the pipe sections at 220 C? HINT: Assume that the welding section is the base plate and the pipe is 1D extended surface (fin) symmetric about the torch melting line. Heat transfer happens by conduction along the pipe thickness in horizontal direction and by convection to the environment. Length thickness Torch melting linearrow_forward

- Calculate the rate of overall heat transfer coefficient for the tube heat exchanger withinner and outer heat transfer coefficient of 670 W/m2 -K and 1880 W/m2 -K, respectively.Thermal conductivity of the tube wall is 27 W/m-K. The diameter and the thickness of thetube are 4 cm and 1.5 mm, respectively. Then, calculate the rate of heat transfer for the tube heatexchanger per meter length if the temperatures of inner and outer surfaces are 100°Cand 52°C, respectively.arrow_forwardA counterflow heat exchanger is designed to cool 1.2 kg/sec of oil withspecific heat Cp = 4.4 kJ/kg-K form 160 OC to 90 OC. Water for coolingis available at 23 OC and flow rate of 2.0 kg/sec. calculate the length ofa 5 cm inside diameter tubing in meters. The overall coefficient of heattransfer is 84 W/m2-K. Show your complete solution.arrow_forwardDetermine the length needed for a simple concentric-tube, parallel flow heat exchanger to transfer heat from hot water to cold water at a rate of 900 W. The heat exchanger consists of two Type K copper (k=386 W/m-degC) tubes. The smaller tube has an inside diameter of 49.8 mm and an outside diameter of 54.0 mm. Assume that both film coefficients are equal to 100 W/sq.m.-degC. The hot water enters at 90 degC and leaves at 50 degC, and the cold water enters at 10 degC and leaves at 40 degC.arrow_forward

- Question 3.1: What effect do finned surfaces have on the overall heat transfer coefficient and hence the performance of a heat exchanger? When is the use of fins most appropriate?arrow_forwardHot water at 90°C flows on the inside of a 2.5-cm-ID steel tube with 0.8-mm wall thickness at a velocity of 4 m/s. This tube forms the inside of a double-pipe heat exchanger. The outer pipe has a 3.75-cm ID, and engine oil at 20°C flows in the annular space at a velocity of 7 m/s. Calculate the overall heat-transfer coefficient for this arrangement. The tube length is 6.0 m.arrow_forwardTask 3Superheated steam at 575ºC is routed from a boiler to the turbine of an electric power plant through steel tubes (k = 35 W/m K) of 300 mm inner diameter and 30 mm wall thickness. To reduce heat loss to the surroundings and to maintain a safe-to-touch outer surface temperature, a layer of calcium silicate insulation (k = 0.10 W/m K) is applied to the tubes, while degradation of the insulation is reduced by degradation of the insulation is reduced by wrapping it in a thin sheet of aluminium having an emissivity of ε= 0.20. The air and wall temperatures of the power plant are 27ºC. Assume that the inner surface temperature of a steel tube corresponds to that of the steam and the convection coefficient outside the aluminium sheet is 6 W/m2 K, (a) What is the minimum insulation thickness needed to ensure that the temperature of the aluminium does not exceed 50ºC? (b) What is the corresponding heat loss per unit meter?(c) What is the difference between lagged and unlagged pipes in…arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi...Mechanical EngineeringISBN:9781305387102Author:Kreith, Frank; Manglik, Raj M.Publisher:Cengage Learning

Principles of Heat Transfer (Activate Learning wi...Mechanical EngineeringISBN:9781305387102Author:Kreith, Frank; Manglik, Raj M.Publisher:Cengage Learning

Principles of Heat Transfer (Activate Learning wi...

Mechanical Engineering

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Cengage Learning

How Shell and Tube Heat Exchangers Work (Engineering); Author: saVRee;https://www.youtube.com/watch?v=OyQ3SaU4KKU;License: Standard Youtube License