Concept explainers

(a)

Interpretation:

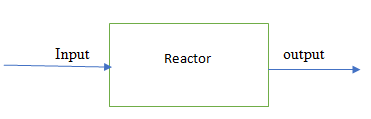

Flow chart of the given process and the degree of freedom for the overall system needs to be calculated.

Concept introduction:

Flow chart of process defines the number of moles reacting with respect to moles formed. It helps in defining the inlet and outlet conditions of reactor.

This gives the relation defined as

Input-output = Accumulation

Degree of freedom is calculated on the basis of number of unknown parameter and number of reactions.

(b)

Interpretation:

Masses of all stream to be calculated.

Concept introduction:

The stream temperature calculation is based on number of moles of acetone, relative saturation, and total pressure at the inlet

Formula for calculation is given as

Here

Mole fraction

Here,

(c)

Interpretation:

Amount of water needed by an individual per day is to be calculated for given condition.

Concept introduction:

Scale factor is calculated on the basis of number of moles reacted to mole of air feed.

(d)

Interpretation:

Amount of heat transfer for the given condition to be calculated.

Concept introduction:

The amount of heat transferred is

Enthalpy of reactant and product depends upon the specific heat and the temperature difference.

Want to see the full answer?

Check out a sample textbook solution

Chapter 9 Solutions

Elementary Principles of Chemical Processes, Binder Ready Version

- Example 8: 900 Kg dry solid per hour is dried in a counter current continues dryer from 0.4 to 0.04 Kg H20/Kg wet solid moisture content. The wet solid enters the dryer at 25 °C and leaves at 55 °C. Fresh air at 25 °C and 0.01Kg vapor/Kg dry air is mixed with a part of the moist air leaving the dryer and heated to a temperature of 130 °C in a finned air heater and enters the dryer with 0.025 Kg/Kg alry air. Air leaving the dryer at 85 °C and have a humidity 0.055 Kg vaper/Kg dry air. At equilibrium the wet solid weight is 908 Kg solid per hour. *=0.0088 Calculate:- Heat loss from the dryer and the rate of fresh air. Take the specific heat of the solid and moisture are 980 and 4.18J/Kg.K respectively, A. =2500 KJ/Kg. Humid heat at 0.01 Kg vap/Kg dry=1.0238 KJ/Kg. "C. Humid heat at 0.055 Kg/Kg 1.1084 KJ/Kg. "C 5:42 Oarrow_forwardQ1: From the Figure below for (=0.2 find the following 1. Rise Time 2. Time of oscillation 3. Overshoot value 4. Maximum value 5. When 1.2 which case will be? 1.6 1.4 1.2 12 1.0 |=0.8- 0.6 0.4 0.8 0.2- 0.6 0.4 0.2 1.2 = 1.0 0 2 4 6 8 10 10 t/Tarrow_forwardPlease, I need solution in detailsarrow_forward

- please, I need solution in detailsarrow_forwardplease, I need solution in detailsarrow_forwardA system, in a closed container, consists of an unknown number of components and three phases. You are told that the system is fully defined by giving you only one mole fraction! What is the number components that is present? 3 1 2 The question is ill-posed.arrow_forward

- A mixture of 2 components in 2 phases are present. You are given the temperature and mole fraction. How many additional variables can be specified before the system is completely determined? none 2 the system is overspecified 1 3arrow_forwardAt a Pressure of 600 mm Hg, match the substance with the boiling temperature. 54.69°C 1. n-Pentane 49.34°C 2. n-Hexane 3. Acetone 29.32°C く 61.40°C 4. Chloroformarrow_forwardA mixture of oil and gas flows through a horizontal pipe with an inside diameter of 150 mm. The respective volumetric flow rates for the oil and gas are 0.015 and 0.29 m³s-1. Determine the gas void frac- tion and the average velocities of the oil and gas. The friction factor may be assumed to be 0.0045. The gas has a density of 2.4 kgm³ and viscosity of 1 x 10-5 Nsm-2. The oil has a density of 810 kgm³ and density of 0.82 Nsm². Answer: 0.79, 20.8 ms-1, 4 ms-1arrow_forward

- 4. An experimental test rig is used to examine two-phase flow regimes in horizontal pipelines. A particular experiment involved uses air and water at a temperature of 25°C, which flow through a horizontal glass tube with an internal diameter of 25.4 mm and a length of 40 m. Water is admitted at a controlled rate of 0.026 kgs at one end and air at a rate of 5 x 104 kgs in the same direction. The density of water is 1000 kgm³, and the density of air is 1.2 kgm3. Determine the mass flow rate, the mean density, gas void fraction, and the superficial velocities of the air and water. Answer: 0.02605 kgs 1, 61.1 kgm³, 0.94, 0.822 ms-1, 0.051 ms-1arrow_forward1. Determine the range of mean density of a mixture of air in a 50:50 oil-water liquid phase across a range of gas void fractions. The den- sity of oil is 900 kgm³, water is 1000 kgm³, and gas is 10 kgm³. 2. Describe, with the use of sketches, the various flow regimes that can exist in a vertical pipe carrying two-phase flow (liquid and gas).arrow_forwardA mixture of high pressure water and steam at a rate of 0.5 kgs-¹ flows up a vertical tube with an inside diameter of 25.4 mm at a pres- sure 22 bar. Determine the type of flow if the mass quality is 1%. The density of the water is 845 kgm³, the density of steam is 10.8 kgm³, and the viscosity of the water is 1.24 x 104 Nsm2. Answer: Slug flowarrow_forward

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The