Concept explainers

8.9 through 8.14 Each of the following problems refers to a rolled-steel shape selected in a problem of Chap. 5 to support a given loading at a minimal cost while satisfying the requirement σm ≤ σall. For the selected design, determine (a) the actual value of σm in the beam, (b) the maximum value of the principal stress σmax at the junction of a flange and the web.

8.10 Loading of Prob. 5.74 and selected W250 × 28.4 shape.

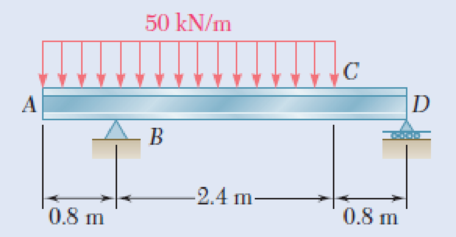

Fig. P5.74

(a)

The actual value of

Answer to Problem 10P

The actual value of

Explanation of Solution

Given information:

Refer to problem 5.74 in chapter 5 in the textbook.

The rolled steel section is

Calculation:

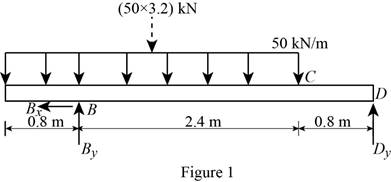

Show the free-body diagram of the beam as in Figure 1.

Determine the vertical reaction at point B by taking moment at point D.

Determine the vertical reaction at point D by resolving the vertical component of forces.

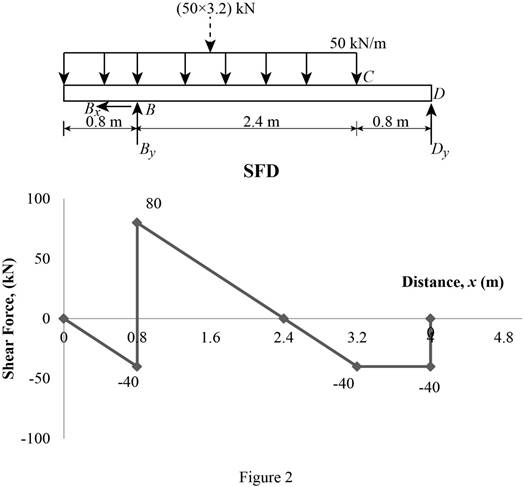

Shear force:

Show the calculation of shear force as follows;

Show the calculated shear force values as in Table 1.

| Location (x) m | Shear force (V) kN |

| A | 0 |

| B (Left) | –40 |

| B (Right) | 80 |

| C | –40 |

| D | –40 |

Plot the shear force diagram as in Figure 2.

Location of the maximum bending moment:

The maximum bending moment occurs where the shear force changes sign.

Refer to Figure 2;

Use the method of similar triangle.

The maximum bending moment occurs at a distance 2.4 m from the left end of the beam.

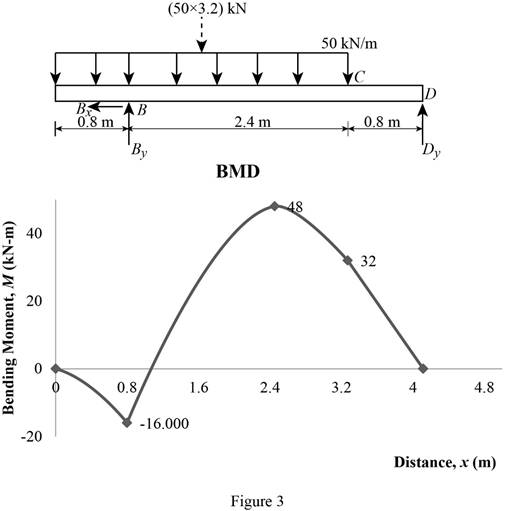

Bending moment:

Show the calculation of the bending moment as follows;

Show the calculated bending moment values as in Table 2.

| Location (x) m | Bending moment (M) kN-m |

| A | 0 |

| B | –16 |

| Max BM | 48 |

| C | 32 |

| D | 0 |

Plot the bending moment diagram as in Figure 3.

Refer to the Figure 3;

The maximum bending moment in the beam is

Write the section a property for a

| Dimension | Unit( |

| d | 259 mm |

| 102 mm | |

| 10.0 mm | |

| I | |

Here, d is depth of the section,

Find the value of C using the relation:

Substitute

Find the maximum value of normal stress

Here,

Substitute

Thus, the actual value of

(b)

The maximum value of principal stress

Answer to Problem 10P

The maximum value of principal stress

Explanation of Solution

Calculation:

Find the value

Here, c is the centroid and

Substitute

Find the area of flange

Here,

Substitute

Find the centroid of flange

Substitute

Find the first moment about neutral axis

Here,

Substitute

At midspan the value of

Find the maximum value of principal stress

Here, actual value of normal stress

Substitute

Find the shear stress

At midspan the value of

Therefore, the shear stress

At section C,

The shear force at point C is

The bending moment about C is

Find the value of

Substitute

Find the shear stress at b

Substitute

Find the maximum shearing stress (R) using the relation:

Here,

Substitute

Determine the maximum value of the principle stress using the relation:

Here, R is the maximum shearing stress and

Substitute

Based on results,

Select the maximum value of principal stress

Thus, the maximum value of principal stress

Want to see more full solutions like this?

Chapter 8 Solutions

EBK MECHANICS OF MATERIALS

- 8.13 Determine the load carrying capacity of a hook of rectangular cross-section. The thickness of the hook is 75 mm; the ra- dius of the inner fibres is 150 mm, while that of the outer fibres is 250 mm. The line of action of the force passes at a distance of 75 mm from the inner fibres. The allowable stress is 70 MN/m².arrow_forwardb. A draw bar between a tractor and a trailer is made from a length of steel with a rectangular cross-section 100 mm by 12 mm. The load is transmitted to the bar via a pin through a 25 mm diameter hole at each end as shown in Fig. 5b. x| i. ii. of 100 O25 x| Fig. 5b CO Y | Y| rum beam If the load P in the bar is 100 kN, determine the following: The stress at the section X-X, shown in Fig. 5b. The stress at the section Y-Y, shown in Fig. 5b. i ort ratelic oltizog muhdillupealiste darrow_forwardA 20 mm diameter steel rod passes concentrically through a bronze tube (200+SN) mm long, 50 mm external diameter and 40 mm internal diameter. The ends of the steel rod are threaded and provided with nuts and washers which are adjusted initially so that there is no end play at 25°C.. 1. Assuming that there is no change in the thickness of the washers, if the stress produced in the steel is (200+SN) MN/m2 when one of the nuts is tightened, the pitch of the thread being 1 mm. Find the number of turns for the nut and stress in bronze tube.2. If the temperature of the steel and bronze is then raised to 4O°C find the changes that will occur in the stresses in both materials. The coefficient of linear expansion per C is 10 x10-6 for steel and 17 x10-6 for bronze. E for steel = 210 GN/m2. E %3D for bronze = 100 GN/m2.. Note: SN = %3D Student number Student Number =32arrow_forward

- Each of the three rolled-steel beams shown (numbered 1, 2, and 3) is to carry a 64-kip load uniformly distributed over the beam. Each of these beams has a 12-ft span and is to be supported by the two 24-ft rolled-steel girders AC and BD. The allowable normal stress for the steel used is 22.5 ksi. Determine the section modulus for each girder and select the most economical W shape for the two girders using the table given below. (Round the final answer to one decimal place.)arrow_forwardProblem Steel block with triaxial loading as shown, y 2" 3" For Steel, E = 29 x 106 Psi y = 0.3 Loads: (Original Loading – Load are Uniformly Distributed Along Their Axis) F; = 48 Kips (T) Fy 60 Kips (C) F2 54 Kips (T) Required: Determine the magnitude F,'of the single uniformly distributed load in the x- direction that would produce the same deformation in the y-direction as the original loading. F + F2 Fyarrow_forward1. A cantilever of square cross section as shown was made of mild carbon steel SAE 1020, as rolled, and was designed to support a static load W = 15 lb. After the beam was installed, it was discovered that the weight W was not static but vibrated, so that actually the beam was subjected to a repeated load. Measurement showed that the weight rose and fell a distance h equal to 0.05 inch. Shortly thereafter the beam fractured at the fillet which had a machined radius of 1/32 in. (a) Make calculations to show and state your conclusion whether or not the beam should have been expected to fail. (b) for the same data, design a new cantilever with the same dimensions except with a fillet radius r= 1/8 in. Determine whether a carbon steel would be necessary, and if so, its SAE or AISI no. 1/2" 3/4". 6"arrow_forward

- |This problem is just like the example problem, but dimension changed so centroid and moment of inertia change, AND the applied load is up and not down. - 3". - 3"-| A vertical force P of magnitude 20 kips is applied at point C located on the axis of symmetry of the cross section of a short column. Knowing that y = 11" determine at the top of column B 2" 6" the stress @ pt A @ pt b @ pt C @ the N.A. A 4" 2" Y' 2" 1/2"arrow_forwardA draw bar between a tractor and a trailer is made from a length of steel with a rectangular cross-section 100 mm by 12 mm. The load is transmitted to the bar via a pin through a 25 mm diameter hole at each end as shown in Fig. 4c. for 100 Fig. 4c If the load P in the bar is 100 kN, determine the following: The stress at the section X-X, shown in Fig. 4c. i (6 marks) ii The stress at the section Y-Y, shown in Fig. 4c. (5 marks)arrow_forwardI need the answer as soon as possiblearrow_forward

- PROBLEM NO. 2 A flanged bolt coupling connects two shafts. The bolt circle diameter is 250 mm in which there are 12 bolts. The allowable shear stress is 50 MPa in the shafts and 23 MPa in the bolts. One shaft is hollow with outside diameter of 100 mm, while the other one is solid of diameter 50 mm. Determine the ratio of the outside and inside diameter of the hollow shaft and the bolt diameter so that both shafts and the flanged bolt coupling are having the same strength in torsion.arrow_forwardAn annular washer distributes the load P applied to a steel rod to a timber support. The rod's diameter is 22 mm, and the washer's inner diameter is 25 mm, which is larger than the hole's permissible outer diameter. Knowing that the axial normal stress in the steel rod is 35 MPa and the average bearing stress between the washer and the timber must not exceed 5 MPa, examine the smallest allowed outer diameter, d, of the washer. %3D %3D +22 mm P Figure 4arrow_forwardI need the answer as soon as possiblearrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY