Concept explainers

When 18,500 Orlando Magic Fans Come to Dinner Video Case

With vast experience at venues such as the American Airlines Arena (in Miami), the Kentucky Derby, and Super Bowls, Chef John Nicely now also plans huge culinary events at Orlando’s Amway Center, home of the Orlando Magic basketball team. With his unique talent and exceptional operations skills, Nicely serves tens of thousands of cheering fans at some of the world’s largest events. And when more than 18,500 basketball fans show up for a game, expecting great food and great basketball, he puts his creative as well as operations talent to work.

Chef John must be prepared. This means determining not only a total demand for all 18,500 fans but also translating that demand into specific menu items and beverages, He prepares a

Chef John frequently changes the menu to keep it interesting for the fans who attend many of the 41 regular season home games each season. Even the culinary preference of the opponent’s fans who may be attending influences the menu. Additionally, when entertainment other than the Magic is using the Amway Center, the demographic mix is likely to be different, requiring additional tweaking of the menu. The size of the wait staff and the kitchen staff change to reflect the size of the crowd; Chef John may be supervising as many as 90 people working in the kitchen. Similarly, the concessions stands, 40% of which have their own grills and fryers, present another challenge, as they are managed by volunteers from nonprofit organizations. The use of these volunteers adds the need for special training and extra enforcement of strict quality standards.

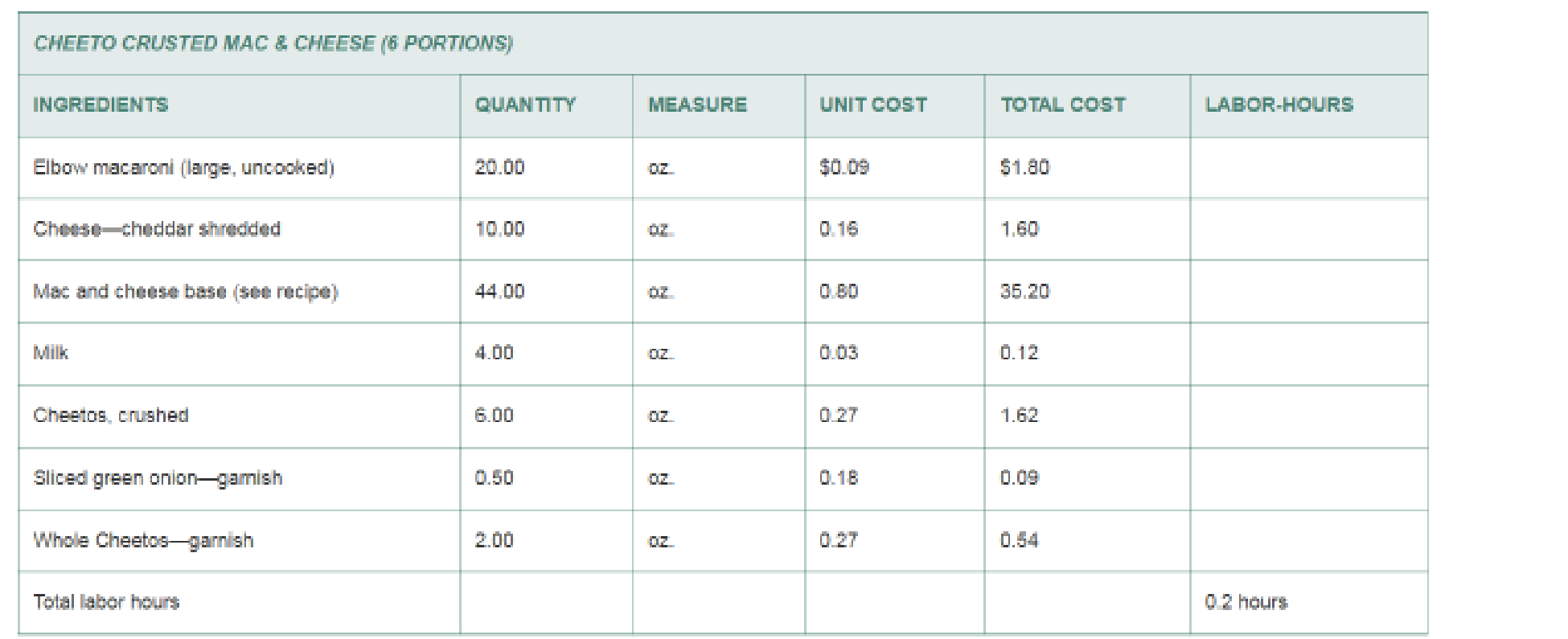

Once deciding on the overall demand and the menu, Chef John must prepare the production specifications (a bill of material) for each item. For the evening game with the Celtics, Chef John is preparing his unique Cheeto Crusted Mac & Cheese dish. The ingredients, quantity, costs, and labor requirements are shown below:

Production Specifications

The yield on this dish is 6 portions, and labor cost is $15 per hour, with fringes. The entire quantity required for the evening is prepared prior to the game and kept in warming ovens until needed. Demand for each basketball game is divided into 5 periods: prior to the game, first quarter, second quarter, half-time, and second half. At the Magic vs. Celtics game next week, the demand (number of portions) in each period is 60, 36, 48, 60, and 12 for the Cheeto Crusted Mac & Cheese dish, respectively.

Discussion Questions*

*You may wish to view the video that accompanies this case before answering the questions.

1. Prepare a bill of material explosion and total cost for the 216 portions of Cheeto Crusted Mac & Cheese.

3. Assuming that there is no beginning inventory of the Cheeto Crusted Mac & Cheese and cooking time for the entire 216 portions is 0.6 hours, when must preparation begin?

Want to see the full answer?

Check out a sample textbook solution

Chapter 14 Solutions

Operations Management

- someone help me to calculate this pls?arrow_forwardJubelien and Joshua have joined forces to start Rosen old Lettuce Products, a processor ofpackaged shredded lettuce. Jubelien has years of food processing experience and Joshua hasextensive commercial food preparation experience. Together with the help from vendors, theycan adequately estimate demand, fixed costs, revenues, and variable cost per 5-pound bag oflettuce. They think a largely manual process will have monthly fixed cost of 37,500Php andvariable cost of 1.75Php per 5-pound bag. A more mechanized process will have fixed costs of75,000Php per month with variable costs of 1.25Php per 5-pound bag. They expect to sell theshredded lettuce for 2.50Php per 5-pound bag.a. What is the break-even quantity for the manual process?b. What is the revenue at the break-even quantity for the manual process?c. What is the break-even quantity for the mechanized process?d. What is the revenue at the break-even quantity for the mechanized process?e. What is the monthly profit or loss of the…arrow_forwardProposed Solution methodology (EXCEL work)arrow_forward

- Step 1. DATA POINTS EXAMPLE FORMULA Step 2. d =Average Demand Per Unit of Time L = Lead time S = Satery Stock C = Container Size N = dL+ S с 29.7 +2.97 6 = Formula N 5.44 = 90 0.33 90x0.33 x0.10 6 (90 x 0.33)+ (90 x 0.33 × 0.10) X 6arrow_forwardPlease kindly assist with the attached?arrow_forward“How many dozen should I put in the proofer?” asked Elizabeth, the new baker at the Sands Cafeteria. Rami El‐Hussieny was the day shift operations manager, and, unfortunately, he did not know how to answer Elizabeth's question. What she wanted to know was simple enough: How many dozen rolls should be placed in the proofer in anticipation of the night's dinner business? The problem was that the frozen dinner roll dough used at the Sands Cafeteria needed to be proof for at least 2 hours prior to being baked for 15 minutes. If too many rolls were proofed, they would never be needed, but they would still have to be baked and made into bread dressing or even tossed out. If too few dozen were proofed and the night was busier than anticipated, they would run out of “Fresh Baked Rolls” (one of the restaurant's signature items), and Rami knew that the night manager would be really upset. It was a daily guess, and sometimes Rami missed the guess! He wondered if a prebaked roll with a shelf life…arrow_forward

- Please assist with the following questionsarrow_forwardRequired information Milford Industries provides medical equipment to oncology and surgical units in major hospitals. Milford allocates indirect costs to five departments and redistributes the IDC for Quality Assurance and Engineering to the other three departments monthly. The table summarizes IDC allocation and direct labor (DL) hours for one month. Department Production Subassemblies Final assembly Quality assurance Engineering NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. Determine the IDC redistribution for each of the three departments. The IDC redistribution is as follows: Production = $ 54.54 Subassemblies = $ IDC Allocation, $ 30,000 20,000 10,000 8,500 26,000 Final assembly = $ 36.36 Actual DL Hours 550 1050 650 18.18arrow_forwardWhat does process planning entail? How would process planning differ for batch and continuous processes?arrow_forward

- Explain Sales and Operations Planning as a Process?arrow_forwardQue#87: Choose the best answer. Level output/workforce strategy: Monthly planning for all the products in same family (and facility) for the next 12 months or so Meeting variations in demand with overtime, subcontracting & part-time/temporary workers Meeting variations in demand with inventories Process of integrating sales forecasts with operations plans Finding the most optimal planarrow_forwardHow do the concepts of master production scheduling and material requirements planning translate to a service organization? Provide an example.arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.