Concept explainers

a)

To develop: A gross requirements plan for all the items.

Introduction:

Gross requirements plan:

The gross requirements plan is the plan where the independent and dependent demand for a product or a component before the on-hand inventory and the scheduled receipts are netted with.

a)

Explanation of Solution

Given information:

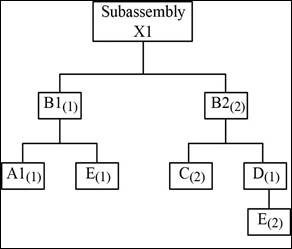

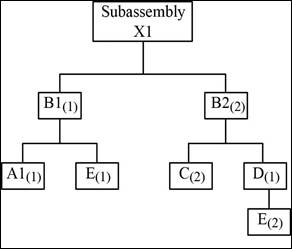

Product structure:

Master production

| MPS for X1 | ||||||

| Period | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 50 | 20 | 100 | |||

Inventory and lead time:

| Item | X1 | B1 | B2 | A1 | C | D | E |

| Lead time | 1 | 2 | 2 | 1 | 1 | 1 | 3 |

| On hand | 50 | 20 | 20 | 5 | 0 | 0 | 10 |

Item X1:

| Week | ||||||||||||

| Item X1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 50 | 20 | 100 | |||||||||

| Order release | 50 | 20 | 100 | |||||||||

The gross requirements are 50, 20 and 100 (1 assembly of X1) in weeks 8, 10 and 12 respectively derived from the master production schedule of X1. The lead time is 1 week. Therefore, the order release will be 50, 20 and 100 in weeks 7, 9 and 11 respectively.

Item B1:

| Week | ||||||||||||

| Item B1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 50 | 20 | 100 | |||||||||

| Order release | 50 | 20 | 100 | |||||||||

The order release of X1 will become the gross requirements of B1. The gross requirements are 50, 20 and 100 (1 assembly of B1) in weeks 7, 9 and 11 respectively. The lead time is 2 weeks. Therefore, the order release will be 50, 20 and 100 in weeks 5, 7 and 9 respectively.

Item B2:

| Week | ||||||||||||

| Item B2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 100 | 40 | 200 | |||||||||

| Order release | 100 | 40 | 200 | |||||||||

The order release of X1 will become the gross requirements of B2. The gross requirements are 100, 40 and 200 (2 assemblies of B2) in weeks 7, 9 and 11 respectively. The lead time is 2 weeks. Therefore, the order release will be 100, 40 and 200 in weeks 5, 7 and 9 respectively.

Item A1:

| Week | ||||||||||||

| Item A1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 50 | 20 | 100 | |||||||||

| Order release | 50 | 20 | 100 | |||||||||

The order release of B1 will become the gross requirements of A1. The gross requirements are 50, 20 and 100 (1 assembly of A1) in weeks 5, 7 and 9 respectively. The lead time is 1 week. Therefore, the order release will be 50, 20 and 100 in weeks 4, 6 and 8 respectively.

Item C:

| Week | ||||||||||||

| Item C | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 200 | 80 | 400 | |||||||||

| Order release | 200 | 80 | 400 | |||||||||

The order release of B2 will become the gross requirements of C. The gross requirements are 200, 80 and 400 (2 assemblies of C) in weeks 5, 7 and 9 respectively. The lead time is 1 week. Therefore, the order release will be 200, 80 and 400 in weeks 4, 6 and 8 respectively.

Item D:

| Week | ||||||||||||

| Item D | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 100 | 40 | 200 | |||||||||

| Order release | 100 | 40 | 200 | |||||||||

The order release of B2 will become the gross requirements of D. The gross requirements are 100, 40 and 200 (2 assemblies of C) in weeks 5, 7 and 9 respectively. The lead time is 1 week. Therefore, the order release will be 100, 40 and 200 in weeks 4, 6 and 8 respectively.

Item E:

| Week | ||||||||||||

| Item E | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 200 | 50 | 80 | 20 | 400 | 100 | ||||||

| Order release | 200 | 50 | 80 | 20 | 400 | 100 | ||||||

The order release of B1 and D will become the gross requirements of E. The gross requirements are 50, 20 and 100 (1 assembly of E) in weeks 5, 7 and 9 respectively. The lead time is 3 weeks. Therefore, the order release will be 50, 20 and 100 in weeks 2, 4 and 6 respectively.

The gross requirements are 200, 80 and 400 (2 assembly of E) in weeks 4, 6 and 8 respectively. The lead time is 3 weeks. Therefore, the order release will be 200, 80 and 400 in weeks 1, 3 and 5 respectively.

b)

To develop: A net requirements plan for all the items.

Introduction:

Net requirements plan:

The net requirements plan is the plan which is established on the gross requirements plan formed by deducting the stock on and the scheduled receipts. If the total requirement is below the safety stock levels, a planned order is made based on the given lot sizing technique.

b)

Explanation of Solution

Given information:

Product structure:

Master production schedule for X1:

| MPS for X1 | ||||||

| Period | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 50 | 20 | 100 | |||

Inventory and lead time:

| Item | X1 | B1 | B2 | A1 | C | D | E |

| Lead time | 1 | 2 | 2 | 1 | 1 | 1 | 3 |

| On hand | 50 | 20 | 20 | 5 | 0 | 0 | 10 |

Item X1:

| Week | ||||||||||||

| Item X1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 50 | 20 | 100 | |||||||||

| Scheduled receipt | ||||||||||||

| On hand (50) | 50 | 0 | 0 | |||||||||

| Net requirement | 0 | 20 | 100 | |||||||||

| Planned order receipt | 20 | 100 | ||||||||||

| Planned order release | 20 | 100 | ||||||||||

Week 8:

The gross requirement is 50 (1 assembly)derived from the master production schedule of X1. The on hand inventory is 50. Hence, the net requirement is 0. The lead time is 1 week. Therefore, there will be no planned order release.

Week 10:

The gross requirement is 20 (1 assembly) derived from the master production schedule of X1. The on hand inventory is 0. Hence, the net requirement is 20. The lead time is 1 week. Therefore, the planned order release will be 20 in week 9 which will be the planned order receipt in week 10.

Week 12:

The gross requirement is 100 (1 assembly) derived from the master production schedule of X1. The on hand inventory is 0. Hence, the net requirement is 100. The lead time is 1 week. Therefore, the planned order release will be 100 in week 11 which will be the planned order receipt in week 12.

Item B1:

| Week | ||||||||||||

| Item B1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 20 | 100 | ||||||||||

| Scheduled receipt | ||||||||||||

| On hand (20) | 20 | 0 | ||||||||||

| Net requirement | 0 | 100 | ||||||||||

| Planned order receipt | 100 | |||||||||||

| Planned order release | 100 | |||||||||||

Week 9:

The gross requirement is 20 (1 assembly) derived from the planned order release of X1. The on hand inventory is 20. Hence, the net requirement is 0. The lead time is 2 weeks. Therefore, there will be no planned order release.

Week 11:

The gross requirement is 100 (1 assembly) derived from planned order release of X1. The on hand inventory is 0. Hence, the net requirement is 100. The lead time is 2 weeks. Therefore, the planned order release will be 100 in week 9 which will be the planned order receipt in week 11.

Item B2:

| Week | ||||||||||||

| Item B2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 40 | 200 | ||||||||||

| Scheduled receipt | ||||||||||||

| On hand (20) | 20 | 0 | ||||||||||

| Net requirement | 20 | 200 | ||||||||||

| Planned order receipt | 20 | 200 | ||||||||||

| Planned order release | 20 | 200 | ||||||||||

Week 9:

The gross requirement is 40 (2 assembly) derived from the planned order release of X1. The on hand inventory is 20. Hence, the net requirement is 20. The lead time is 2 weeks. Therefore, the planned order release will be 20 in week 7 which will be the planned order receipt in week 9.

Week 11:

The gross requirement is 200 (2 assembly) derived from planned order release of X1. The on hand inventory is 0. Hence, the net requirement is 200. The lead time is 2 weeks. Therefore, the planned order release will be 200 in week 9 which will be the planned order receipt in week 11.

Item A1:

| Week | ||||||||||||

| Item A1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 100 | |||||||||||

| Scheduled receipt | ||||||||||||

| On hand (5) | 5 | |||||||||||

| Net requirement | 95 | |||||||||||

| Planned order receipt | 95 | |||||||||||

| Planned order release | 95 | |||||||||||

Week 9:

The gross requirement is 100 (1 assembly) derived from the planned order release of B1. The on hand inventory is 5. Hence, the net requirement is 95. The lead time is 1 week. Therefore, the planned order release will be 95 in week 8 which will be the planned order receipt in week 9.

Item C:

| Week | ||||||||||||

| Item C | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 40 | 400 | ||||||||||

| Scheduled receipt | ||||||||||||

| On hand (0) | 0 | 0 | ||||||||||

| Net requirement | 40 | 400 | ||||||||||

| Planned order receipt | 40 | 400 | ||||||||||

| Planned order release | 40 | 400 | ||||||||||

Week 7:

The gross requirement is 40 (2 assembly) derived from the planned order release of B2. The on hand inventory is 0. Hence, the net requirement is 40. The lead time is 1 week. Therefore, the planned order release will be 40 in week 6 which will be the planned order receipt in week 7.

Week 9:

The gross requirement is 400 (2 assembly) derived from planned order release of B2. The on hand inventory is 0. Hence, the net requirement is 400. The lead time is 1 week. Therefore, the planned order release will be 400 in week 8 which will be the planned order receipt in week 9.

Item D:

| Week | ||||||||||||

| Item D | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 20 | 200 | ||||||||||

| Scheduled receipt | ||||||||||||

| On hand (0) | 0 | 0 | ||||||||||

| Net requirement | 20 | 200 | ||||||||||

| Planned order receipt | 20 | 200 | ||||||||||

| Planned order release | 20 | 200 | ||||||||||

Week 7:

The gross requirement is 20 (1 assembly) derived from the planned order release of B2. The on hand inventory is 0. Hence, the net requirement is 20. The lead time is 1 week. Therefore, the planned order release will be 20 in week 6 which will be the planned order receipt in week 7.

Week 9:

The gross requirement is 200 (1 assembly) derived from planned order release of B2. The on hand inventory is 0. Hence, the net requirement is 200. The lead time is 1 week. Therefore, the planned order release will be 200 in week 8 which will be the planned order receipt in week 9.

Item E:

| Week | ||||||||||||

| Item E | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Gross requirements | 40 | 400 | 100 | |||||||||

| Scheduled receipt | ||||||||||||

| On hand (10) | 10 | 0 | 0 | |||||||||

| Net requirement | 30 | 400 | 100 | |||||||||

| Planned order receipt | ||||||||||||

| Planned order release | 30 | 400 | 100 | |||||||||

Week 6:

The gross requirement is 40 (2 assembly) derived from the planned order release of B2. The on hand inventory is 10. Hence, the net requirement is 30. The lead time is 3 weeks. Therefore, the planned order release will be 30 in week 3 which will be the planned order receipt in week 6.

Week 8:

The gross requirement is 400 (2 assembly) derived from the planned order release of B2. The on hand inventory is 0. Hence, the net requirement is 400. The lead time is 3 weeks. Therefore, the planned order release will be 400 in week 5 which will be the planned order receipt in week 8.

Week 9:

The gross requirement is 100 (1 assembly) derived from the master production schedule of B1. The on hand inventory is 0. Hence, the net requirement is 100. The lead time is 3 weeks. Therefore, the planned order release will be 100 in week 6 which will be the planned order receipt in week 9.

Want to see more full solutions like this?

Chapter 14 Solutions

Principles Of Operations Management

- The supply chain is a conventional notion, but organizations are only really interested in making products that they can sell to customers. Provided they have reliable supplies of materials and reasonable transport for finished products, logistics is irrelevant. Do you think this is true? If yes, explain, and if no, clearly explain as well.arrow_forwardworking as a program operations managerarrow_forward12 X1, X230 1 x =0x2 write the Following linear Programming model by 1- general Form Canonical Forms Canonical formY 2- Standard Form Max Z=35X+ 4 X 2 +6 X3 ST. X+2X2-5x3 = 40 3X, + 6X2 + 7x 3 = 30 7x, +lox2 x3 = 50 X3 X 2 X 3 <0arrow_forward

- a/ a Minimum cost assign each worker for one job at Jobs J1 12 33 WI 2 4 6 W2 5 W3 5 33 6 7arrow_forwardوبة واضافة هذه القيمة الى القيم Ex: Assign each job for each worker at minimum total Cost عمل لكل عامل وبأقل كلفة ممكنة obs الأعمال Workors العمال J1 J2 J3 J4 W₁ 15 13 14 12 W2 11 12 15 13 W3 13 12 10 11 W4 15 17 14 16arrow_forwardThe average completion time (flow time) for the sequence developed using the FCFS rule = 11.75 days (round your response to two decimal places). The percentage utilization for the sequence developed using the FCFS rule = 42.55 % (enter your response as a percentage rounded to two decimal places). b) Using the SPT (shortest processing time) decision rule for sequencing the jobs, the order is (to resolve a tie, use the order in which the jobs were received): An Alabama lumberyard has four jobs on order, as shown in the following table. Today is day 205 on the yard's schedule. In what sequence would the jobs be ranked according to the decision rules on the left: Job Due Date A 212 B 209 C 208 D 210 Duration (days) 6 3 3 8 Sequence 1 Job B 2 3 4 A D The average tardiness (job lateness) for the sequence developed using the SPT rule = 5.00 days (round your response to two decimal places). The average completion time (flow time) for the sequence developed using the SPT rule = 10.25 days…arrow_forward

- With the aid of examples, fully discuss any five (5) political tactics used in organisations.arrow_forwarda. With the aid of examples, define discrimination. b. Fully discuss any four (4) types of discrimination in the workplacearrow_forwardRead the Following Extract and Answer the Questions that Follows:The word politics has a somewhat negative connotation. It suggests that someone is attempting touse means or to gain ends that are not sanctioned by the organisation. Political behaviour, as we’vedefined it is quite neutral. Similarly, power is not inherently negative. Whether a person viewspower and politics as unsavoury topics depends on several considerations, most important perhapsbeing where the individual stands on a specific issue in each situation. Nonetheless, most managersare reluctant to admit to political character of their own work settings.Discuss any Five (5) Political tactics you know.arrow_forward

- Describe current features of Cigna Accredo pharmacy own appraisal forms and compare the system used against the textbook’s description of desirable features of appraisal forms. What improvements would you recommend and why?arrow_forwardProvide a recommendation of a combination of different methods of performance data that could be used to arrive at an overall score for each person being rated in cigna Accredo pharmacy. Explain the comprehensive system you have recommended and why you have chosen this combination of tools. Support your answer with research.arrow_forwardAlready got wrong answer Plz Don't use chatgptarrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.