Concept explainers

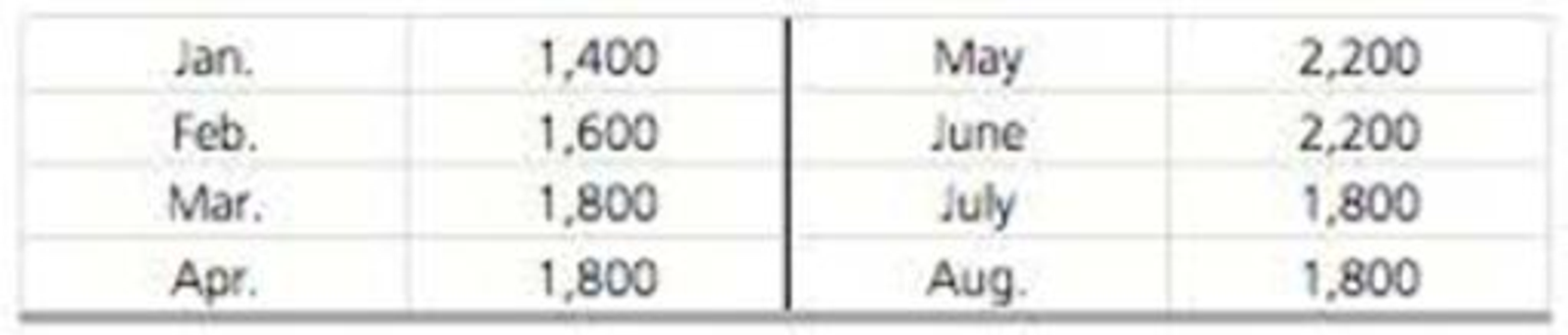

The president of Hill Enterprises, Terri Hill, projects the firm’s aggregate demand requirements over the next 8 months as follows:

Her operations manager is considering a new plan, which begins in January with 200 units on hand. Stockout cost of lost sales is $100 per unit. Inventory holding cost is $20 per unit per month. Ignore any idle-time costs. The plan is called plan A.

Plan A: Vary the workforce level to execute a strategy that produces the quantity demanded in the prior month. The December demand and rate of production are both 1,600 units per month. The cost of hiring additional workers is $5,000 per 100 units. The cost of laying off workers is $7,500 per 100 units. Evaluate this plan.

Note: Both hiring and layoff costs are incurred in the month of the change. For example, going from 1,600 in January to 1,400 in February incurs a cost of layoff for 200 units in February.

Want to see the full answer?

Check out a sample textbook solution

Chapter 13 Solutions

Principles Of Operations Management

- The president of Hill Enterprises, Terri Hill, projects the firm's aggregate demand requirements over the next 8 months as follows: alculator DEPREFERESSESES Cara be Her operations manager is considering a new plan, which begins in January with 200 units of inventory on hand. Stockout cost of lost sales is $65 per unit. Inventory holding cost is $20 per unit per month. Ignore any idle-time costs Evaluate the following plan. This exercise contains only Plan E. Plan E: Keep the current workforce, which is producing 1,600 units per month, and subcontract to meet the rest of the demand. Subcontract cost is $75 per unit. mummill M Pla $100433443 January February March April MESS Month 0 December 1 January 2 February 3 March 4 April 5 May 6 June 7 July 8 August Ask my instructor 1,400 1,600 1,800 1,800 Demand 1.400 1,600 1,800 1,800 2,200 2,100 1,800 1.400 May June July August Production (Units) 1,600 1,600 1,600 1,600 1,600 1,600 1,600 1,600 2,200 2.100 1.800 1,400 S Plan E Subcontract…arrow_forwardThe S&OP team at Kansas Furniture, has received estimates of demand requirements as shown in the table. Assuming one-time stockout costs for lost sales of $125 per unit, inventory carrying costs of $20 per unit per month, and zero beginning and ending inventory, evaluate the following plan on an incremental cost basis: Plan B: Vary the workforce to produce the prior month's demand. The firm produced 1,300 units in June. The cost of hiring additional workers is $30 per unit produced. The cost of layoffs is $65 per unit cut back. (Enter all responses as whole numbers.) Note: Both hiring and layoff costs are incurred in the month of the change (i.e., going from production of 1,300 in July to 1200 in August requires a layoff (and related costs) of 100 units in August). Layoff (Units) Ending Inventory Hire Stockouts Month Demand Production (Units) (Units) 1 July 1200 2 August 1300 3 September 1200 4 October 1700 5 November 1650 6. December 1650arrow_forwardThe S&OP team at Kansas Furniture, led by David Angelow, has received estimates of demand requirements as shown in the table. Assuming one-time stockout costs for lost sales of $125 per unit, inventory carrying costs of $25 per unit per month, and zero beginning and ending inventory, evaluate the following plan on an incremental cost basis: Plan B: Vary the workforce to produce the prior month's demand. Demand was 1,300 units in June. The cost of hiring additional workers is $30 per unit produced. The cost of layoffs is $60 per unit cut back. (Enter all responses as whole numbers.) Note: Both hiring and layoff costs are incurred in the month of the change (i.e., going from production of 1,300 in July to 1300 in August requires a layoff (and related costs) of 0 units in August). Month Hire Demand Production (Units) Layoff Ending (Units) Inventory Stockouts (Units) 1 July 1300 2 August 1150 3 September 1100 4 October 1600 5 November 1900 6 December 1900arrow_forward

- 3) AGGREGATE PLANNING Mark Tuan, Operations Manager at GOT7 Furniture, has received the following estimates of demand requirements: January 1,100 February 1,200 March 1,400 April 1,800 May 1,800 June 1,600 Assuming stockout costs for lost sales of RM100 per unit, inventory carrying costs of RM25 per unit per month, and a zero beginning and ending inventory. Analyze the extra cost if the company vary the workforce, which performs at a current production level of 1,300 units per month. The cost of hiring additional workers is RM3,000 per 100 units produced. The cost of layoffs is RM6,000 per 100 units cut back.arrow_forwardThe planner at a company that makes garden tractors is about to prepare an aggregate production plan that will cover the next 6 months. She has collected the following information: Month Demand Forecast Above the available capacity through permanent workforce 1 1,000 2 1,000 3 2,000 4 3,000 5 4,000 6 1,000 Total: 12,000 Production per month = 20 units per worker Initial inventory = 500 units Desired ending inventory (at the end of month 6) = 0 units Cost: Hire cost = $500 per temporary worker Inventory = $10 per tractor per month Backorder = $150 per tractor per month The optimum aggregate plan is: Month 1 2 3 4 5 6 Total Forecast Demand above regular capacity 1,000 1,000 2,000 3,000 4,000 1,000 12,000 # of temporary workers required 50 50 100 150 200 50 Temp. Workers hired 25 25 50 75 0 0 Temp. workers laid off 0…arrow_forwardEZ-Windows, Inc. manufacturers replacement windows for the home remodeling business. In January, the company produces 15,000 windows and ended the month with 9,000 windows in inventory. EZ-Windows' management team would like to develop a production schedule for the next three months. A smooth production schedule is obviously desirable because it maintains the current workforce and provides a similar month-to-month operation. However, given the sales forecasts, the productioncapacities, and the storage capabilities as shown in Table 2, the management team does not think a smooth production schedule with the same production quantity each month possible.The company's cost accounting department estimates that increasing production by one window from one month to the next will increase total costs by $1.00 for each unit increase in the production level. In addition, decreasing production by one unit from one month to the next will increase total costs by $0.65 for each unit decrease in the…arrow_forward

- Directions Select one of these concepts: How the Aggregate Operations Plan combines required materials, capacity, and staffing. Inputs and application of the different Production Planning Strategies: Chase strategy, level strategy, Stable workforce Aggregate planning techniques that minimize the costs of operations. Application of Materials Requirement Planning methods as a manufacturing scheduling tool Use of Bills of Materials and Lot Sizing in MRP systemsarrow_forwardJAYB, manager of a Fabrication company, has the following aggregate demand requirements and other data for the upcoming four quarters. Table 5: Forecast and cost information [Jadual 5: Maklumat Ramalan dan kos] Quarter [Suku] Demand [Permintaan] Previous quarter's output [Keluaran suku sebelumnya] 1,500 units 1 1,400 Beginning inventory [Inventori awal] 200 units 2 1,000 Hiring workers [Pengambilan pekerja] RM6 per unit 3 1,500 Laying off workers [Pembuangan pekerja] RM11 per unit 4 1,300 Unit cost [Kos unit] RM30 per unit With the information given, JAYB wants you to calculate the total cost of using chase strategy by hiring and layoff workers.arrow_forwardDevelop a chase aggregate plan for Draper using apermanent workforce of 12 employees supplemented by overtime.All demand must be met each period.(a) Show what would happen if this plan were implemented.(b) Calculate the costs associated with this plan.(c) Evaluate the plan in terms of cost, customer service,operations, and human resources.arrow_forward

- The opening backlog is 800 units. Forecast demand is as shown here. Calculate theweekly production for level production if the backlog is to be reduced to 100 units.arrow_forwardManufacturing firms should use demand leading instead of demand trailing capacity strategy. Discuss.arrow_forwardAssess plan A: strategy that hires and fires employees to meet the forecasted demand. Assess plan B: strategy that produces 1,200 cases per quarter and meets the forecasted demand with inventory and subcontracting.arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.