OPERATIONS MANAGEMENT(LL)-W/CONNECT+

12th Edition

ISBN: 9781308452647

Author: Stevenson

Publisher: MCG/CREATE

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 11, Problem 21P

Prepare a master

Use a production lot size of 75 units and no beginning inventory.

Expert Solution & Answer

Trending nowThis is a popular solution!

Students have asked these similar questions

Prepare a master schedule given this information: The forecast for each week of an eight-week schedule is 60

units. The MPS rule is to schedule production if the projected on-hand Inventory would be negative without it.

Customer orders (committed) are as follows:

Week

1

2

3

Customer Orders

54

38

25

20

Use a production lot size of 73 units and no beginning inventory. (In the ATP row, enter a value of 0 (zero) In any

perlods where ATP should not be calculated. Leave no cells blank - be certain to enter "0" wherever required.)

June

July

MPS

ATP

Forecast

Customer Orders

Projected On-Hand Inventory

60

54

2

60

38

3

60

25

4

60

20

5

60

0

6

60

0

7

60

0

8

60

0

please answer within 30 minutes.

Prepare a master schedule based on the following information:

Week

1

2

3

4

5

6

7

8

Forecast

500

500

600

600

750

750

900

800

Orders

540

470

325

200

105

45

10

0

Currently there are 700 units in inventory. Policy calls for a fixed order quantity of 1250 units.

Can you receive another order for 250 items in week 1? Why?

How many orders can be received in each period without altering the plan.

If there are 1250 items in stock, what would be the answer of questions 2 and 3?

Chapter 11 Solutions

OPERATIONS MANAGEMENT(LL)-W/CONNECT+

Ch. 11 - What three levels of planning involve operations...Ch. 11 - What are the three phases of intermediate...Ch. 11 - Prob. 3DRQCh. 11 - Why is there a need for aggregate planning?Ch. 11 - What are the most common decision variables for...Ch. 11 - Prob. 6DRQCh. 11 - Briefly discuss the advantages and disadvantages...Ch. 11 - What are the primary advantages and limitations of...Ch. 11 - Briefly describe the planning techniques listed as...Ch. 11 - What are the inputs to master scheduling? What are...

Ch. 11 - Prob. 11DRQCh. 11 - What general trade-offs are involved in master...Ch. 11 - Who needs to interface with the master schedule...Ch. 11 - How has technology had an impact on master...Ch. 11 - Service operations often face more difficulty in...Ch. 11 - Name several behaviors related to aggregate...Ch. 11 - Compute the total cost for each aggregate plan...Ch. 11 - A manager would like to know the total cost of a...Ch. 11 - Determine the total cost for this plan given the...Ch. 11 - a. Given the following forecast and steady regular...Ch. 11 - Manager T. C. Downs of Plum Engines, a producer of...Ch. 11 - Manager Chris Channing of Fabric Mills, Inc., has...Ch. 11 - SummerFun. Inc., produces a variety of recreation...Ch. 11 - Nowjuice, Inc., produces Shakewell fruit juice. A...Ch. 11 - Wormwood, Ltd., produces a variety of furniture...Ch. 11 - Refer to Solved Problem 1. Prepare two additional...Ch. 11 - Refer to Solved Problem 1. Suppose another option...Ch. 11 - Prob. 12PCh. 11 - Prob. 13PCh. 11 - Prob. 14PCh. 11 - Prob. 15PCh. 11 - Refer to Example 3. Suppose that regular-time...Ch. 11 - Prob. 17PCh. 11 - Prob. 18PCh. 11 - Prepare a master production schedule for...Ch. 11 - Update the master schedule shown in Figure 11.11...Ch. 11 - Prepare a master schedule like that shown in...Ch. 11 - Determine the available-to-promise (ATP)...Ch. 11 - Prepare a schedule like that shown in Figure 11.12...Ch. 11 - The objective is to choose the plan that has the...Ch. 11 - Prob. 2CQ

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

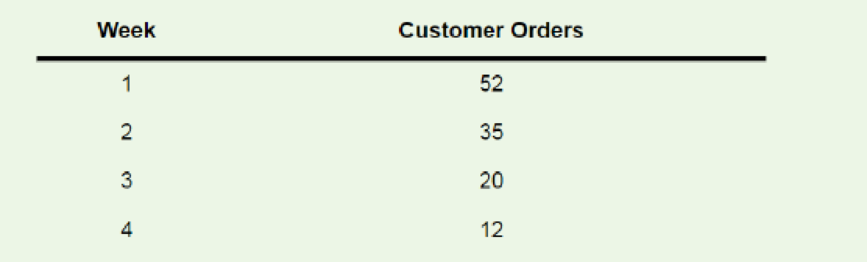

- Prepare a Master Schedule like that shown in Figure 11.11 given the following information:The forecast for each week of an eight-week schedule is 50 units. The MPS tule is to schedule production if the projected on-hand inventory would be negative without it. Customer orders (committed) are as follows:Week 1.2.3.4Customer Orders 52.35.20.12Use a production lot size of 75 units and no beginning inventory.arrow_forwardDon't mind the number i already wrotearrow_forwardWeek 1 3. 4 Forecast 45 45 45 45 Customer Order 42 45 42 50 Given the following data, calculate the projected available balance. The demand time fence is the end of week 3, the order quantity is 100, and 40 are available at the beginning of the periodarrow_forward

- Please do not give solution in image format thankuarrow_forwardThe main input for master scheduling schedule is: O a. Long term forecasting O b. Aggregate production (capacity) plan (aggregate planning) O c. Material requirements planning (MRP) O d. None of the above Which of the following best describes the last step to developing a master production schedule? O a. Check preliminary MPS against available capacity O b. Check the MPS against the production plan to ensure they match O c. Resolve differences between the preliminary MPS and available capacity O d. Design a preliminary MPS MRP systems are: O a. Substitutes for fixed order point/order quantity systems. O b. Appropriate for all end items in the product line. O c. Intended to determine an appropriate master production schedule. Od. Intended to reduce inventory requirements, production lead times, and delivery times to customers. O e. Intended to be used for independent demand items.arrow_forwardPrepare a master production schedule with the information given as follows. The forecast for each week of am eight week schedule is 50 units. The MPS rule is to schedule production if the projected on hand inventory would be negative without it. Customer orders are as follows. Production lot size is 75, safety stock is 10 and no beginning on hand inventory. Calculate available to promise (ATP) quantity for each period. Week Customer Orders 1 52 2 35 3 20 4 12 Period Forecast Cust.Ord. SS Proj. OH MPS ATParrow_forward

- The opening backlog is 800 units. Forecast demand is as shown here. Calculate theweekly production for level production if the backlog is to be reduced to 100 units.arrow_forwardAn end item’s demand forecasts for the next 10 weeks are30, 30, 30, 30, 20, 20, 30, 30, 30, and 30 units. The current on-hand inventory is 100 units. The order policy is to produce inlots of 75. The booked customer orders for the item, startingwith week 1, are 15, 38, 7, 5, 0, 3, 10, 0, 0, and 0 units. The leadtime is 2 weeks.a. Develop an MPS for this end item.b. The marketing department has received five orders forthis item in the following sequence:Order 1 is for 20 units to be delivered in period 1Order 2 is for 75 units to be delivered in period 4Order 3 is for 90 units to be delivered in period 6 Order 4 is for 75 units to be delivered in period 7Order 5 is for 90 units to be delivered in period 10 Assuming that the prospective MPS you developed in part (a)does not change, which orders would you be able to acceptbased on the available to promise (ATP)?arrow_forwardGiven the projected demands for the next six months, prepare aggregate plan must wind up with no units in ending inventory in Period 6. Regular time capacity is 150 units per month. Overtime cost is $20 per unit, backorder cost is $30 per unit, inventory holding cost is $10 per unit based on maximum, subcontracting cost is $40 per unit, regular time cost of $20 per unit, and beginning inventory is 10. Month 1 2 3 45 6 Forecast 150 170 140 160 130 160 a. Prepare an aggregate plan with inventory and backlog allowed. Overtime and subcontracting are not allowed. b. Prepare an aggregate plan if the management decided to switch to chase strategy. They only allow backlog if absolutely needed. Regular production capacity is now 160.arrow_forward

- 3. The MPS planner at Murphy Motors uses MPS time-phased records for planning end-item pro- duction. The planner is currently working on a schedule for the P24, one of Murphy's top-selling motors. The planner uses a production lot size of 70 and a safety stock of 5 for the P24 motor. Week On hand 30 30 30 1 2 3 4 5 6 7 8 40 40 40 45 45 13 8 4 Item: P24 Forecast Orders Projected available balance 20 Available-to-promise MPS a. Complete the MPS time-phased record for product P24. b. Can Murphy accept the following orders? Update the MPS time-phased record for accepted orders. Amount 40 Order Desired Week 1 4 2 6 3 30 2 4 25 3 30 4882 7623arrow_forwardPrepare a master schedule given this information: It is now the end of week 1; customer orders are 25 for week 2, 16 for week 3, 11 for week 4, 8 for week 5, and 3 for week 6. Use the MPS rule of ordering production when projected on-hand inventory would be negative without production. Suppose that there were 64 pumps in inventory at the beginning of week 1. A production lot size of 70 pumps is used. (Leave no cells blank - be certain to enter "0" wherever required.)arrow_forwardPrepare a master schedule given this information: It is now the end of week 1; customer orders are 25 for week 2, 16 for week 3, 11 for week 4, 8 for week 5, and 3 for week 6. Use the MPS rule of ordering production when projected on-hand inventory would be negative without production. Suppose that there were 64 pumps in inventory at the beginning of week 1. A production lot size of 70 pumps is used. (Leave no cells blank - be certain to enter "0" wherever required.) Forecast Customer orders (committed) Projected on-hand inventory MPS ATP 1 30 33 2 June 30 25 3 30 16 4 30 11 5 40 8 6 July 40 3 P 7 40 P 8 40arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Inventory Management | Concepts, Examples and Solved Problems; Author: Dr. Bharatendra Rai;https://www.youtube.com/watch?v=2n9NLZTIlz8;License: Standard YouTube License, CC-BY