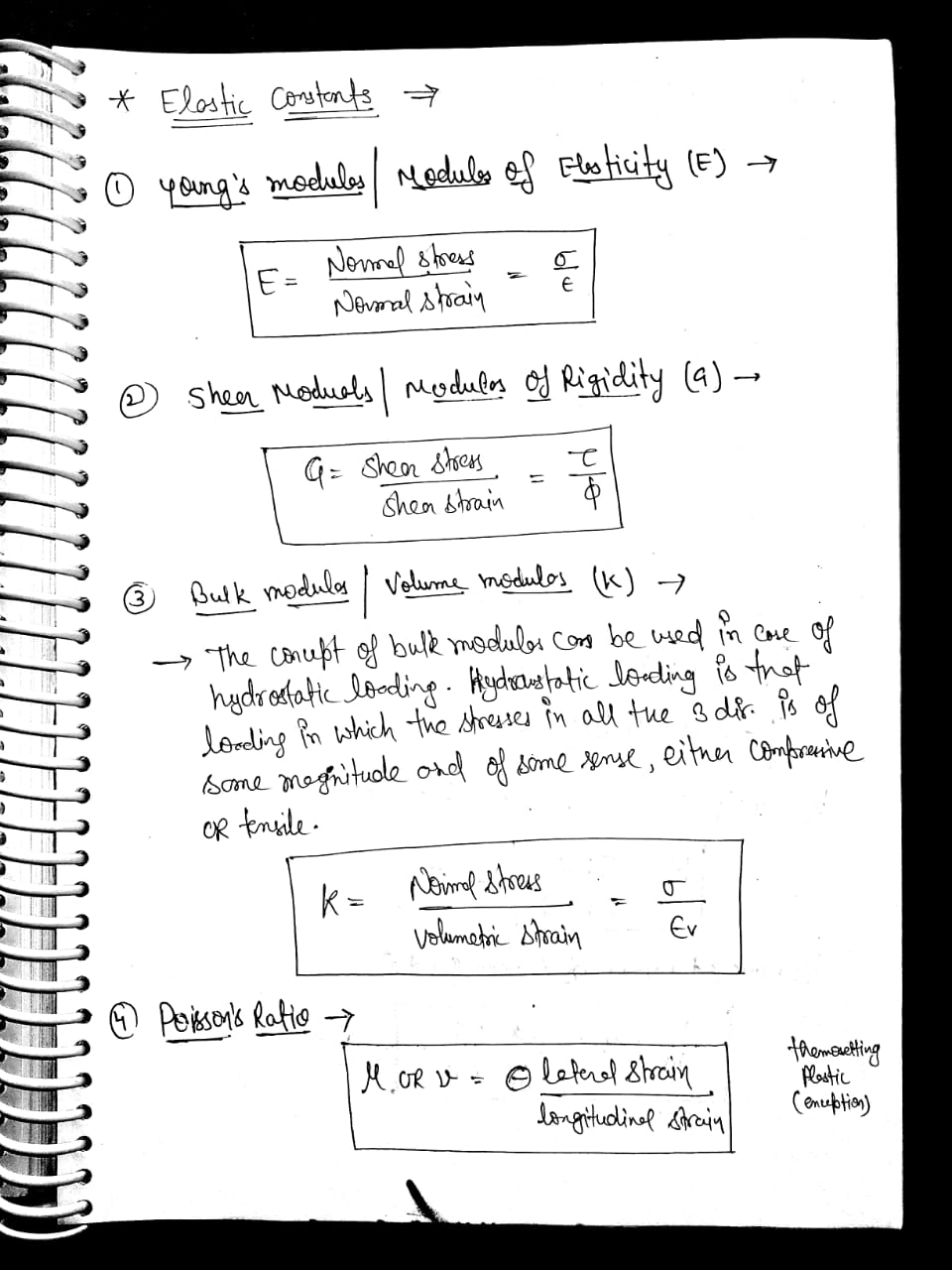

When an external force acts on a body, the body tends to undergo some deformation. If the external force is removed and the body comes back to its origin shape and size, the body is known as elastic body. This property, by virtue of which certain materials return back to their original position after the removal of the external force, is called elasticity. We can explain these behaviours using following elastic constants.

Young’s modulus or Modulus of elasticity (E)

Shear modulus or Modulus of Rigidity (G)

Bulk modulus (K)

You are required to submit a report explaining these elastic constants and explaining the relations between these elastic constants. (You can use the relation with Poisson’s Ratio and get the relation between E, G and K.)

Step by stepSolved in 2 steps with 2 images

- The Hooke's Law expression relating normal stress and normal strains with a single elastic modulus and single Poisson's ratio is appropriate at a single temperature and for both isotropic and anisotropic materials. O True O Falsearrow_forwardsubmit to blackboard. 1- The stress-strain diagram for human tendon having an original diameter of 0.8 cm. and an initial length of 3 cm. is given in the figure. a) Determine approximately the modulus of elasticity for the material (E?). b) Determine the load (Pvield) on the specimen that causes yielding (make sure to include the yielding stress (o,) in the answer). c) Determine the ultimate load (Pultimate) the specimen will support (make sure to include the ultimate stress in the answer). MPа 70 60 50 40 30 20 10 10-3 80 & 0. 20 40 60 (Ans: because it needs reading from a graph and the final answer is estimation and not unique, the final results are not given)arrow_forward(Solid Mechanics) Explain how to construct the upper right corner (red boundary indicated below) of the envelope for the maximum shear stress criterion.arrow_forward

- 2. A 10 mm diameter cylindrical specimen of an aluminium alloy is loaded in uniaxial tension in a testing machine. a) If the specimen begins to yield at a load of 30 kN, what is the yield stress of the material? b) At the point where yielding begins, the measured increase in length between two points initially 50 mm apart is 0.27 mm. At what strain does yielding occur? c) If the load-deflection curve is linear up to the yield point, what is the elastic modulus of the material? d) If the diameter of the specimen was reduced by 18 um at the yield point, what is the Poisson's ratio of the material? [ans.: (a) 382 MPa; (b) 5.4E-3; (c) 70.7 GPa; (d) 0.333]arrow_forward1. For the stress-strain curve shown below, please estimate the properties indicated. (a) Fracture Strain Please do your work on a separate sheet of paper, and put your answers in the boxes on the right. Be sure to include the proper symbol and units. Stress Strain 70 60 50 Stress (ksi) 240 30 20 10 70 0 0.000 60 50 Stress (ksi) 40 20 10 KULL 0 0.000 0.010 0.050 0.100 Strain (in/in) Stress Strain 0.020 0.030 Strain (in/in) 0.040 0.150 0.050 (b) Ultimate Tensile Stress (c) Fracture Stress (d) Proportional Limit (e) Elastic Modulus (1) Yield Stress (g) Tensile Toughness (Modulus of Toughness) (h) Modulus of Resiliencearrow_forwardIf a material had a modulus of elasticity of 2.1 × 106 kgf/cm2 and a modulus of rigidity of 0.8 × 106 kgf/cm2 then the approximate value of the Poisson's ratio of the material would be (a) 0.26 (b) 0.31 (c) 0.47 (d) 0.5arrow_forward

- A structural member 10 cm long must be able to support a load of 50,000 N without experiencing any plastic deformation. Given the following data for brass, steel, aluminum, and titanium, rank them from least to greatest weight in accordance with these criteria. Yield strength Ultimate tensile Alloy Density (g/cm3) (MPa) strength (MPa) Brass 415 600 8.5 Steel 860 800 7.9 Aluminum 310 435 2.7 * 700 Titanium 550 4.5arrow_forwardQ2: A fiberglass composite consists of a matrix of vinyl ester and reinforcing fibers of E-glass. The volume fraction of E-glass is 30%. The density of the vinyl estiser 0.882 g/cm³, and its modulus of elasticity is 3.6 GPa. The density of E-glass is 2.6 g/cm³, and its modulus of elasticity is 76 GPa. A section of composite 1 cm by 25 cm by 2 m is fabricated with the E-glass fibers running longitudinally in the 2000 mm direction. Determine: (a) The masses of vinyl ester and E-glass fibers. (b) The density of the composite. (c) The composite modulus of elasticity in the longitudinal and the perpendicular directions of the glass fibers. (d) If the tensile strength of the glass fibers, is 1 GPA and the tensile strength of the epoxy matrix is 60 MPa, find the tensile strength of the composite in the longitudinal direction.arrow_forwardA string 4 mm in diameter has original length 2 m. The string is pulled by a force of 200 N. If the final length of the spring is 2.02 m, determine : (a) stress (b) strain (c) Young's modulus -arrow_forward

- A railroad track is laid at a temperature of 10°C with gaps of 0.008 m between the ends of the rails. The rails are 20 m long. Coefficient of thermal expansion is 11.25 x 106/°C. Modulus of elasticity = 200000 MPa. Which of the following gives the actual deformation of the rails that will result from a temp. of 65°C? %3D Select one: O a. 0.0124 m O b. 0.0214 m O c. 0.0142 m O d. 0.0022 marrow_forwardA steel column is a cylinder 6.8 m long and 0.35 m in diameter. What is the change in length of the column when it experiences a tensile stress resulting from the application of a 3600 N force? The elastic modulus for steel is 20 × 1010 Nm2/kg2. ΔL = marrow_forwardRigid bar ABCD is loaded and supported. Steel [E=30,000 ksi] bars (1) and (2) are unstressed before the load P is applied. Bar (1) has a cross-sectional area of 0.625 in.2 and bar (2) has a cross-sectional area of 1.25 in. 2. After load P is applied, the strain in bar (2) is found to be 900 με. If there is a clearance of 0.05 in. in the pin connection at C, determine: (a) the stresses in bars (1) and (2).(b) the vertical deflection of point D.(c) the load P.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY