Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Solve the Graph

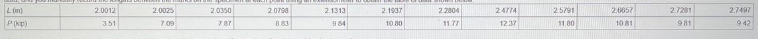

Transcribed Image Text:You have built the majority of the tension testing machine, but much of the instrumentation is still being assembled. To test the machine, you perform a test on a steel specimen with known properties. The machine provides you with the given load data, and you manually record the lengths between the marks on the specimen at each point using an extensometer to obtain the table of data shown below.

| \( L \) (in) | 2.0012 | 2.0025 | 2.0350 | 2.0798 | 2.1313 | 2.1937 | 2.2804 | 2.4774 | 2.5791 | 2.6657 | 2.7281 | 2.7497 |

|--------------|--------|--------|--------|--------|--------|--------|--------|--------|--------|--------|--------|--------|

| \( P \) (kip)| 3.51 | 7.09 | 7.87 | 8.83 | 9.84 | 10.80 | 11.77 | 12.37 | 11.80 | 10.81 | 9.81 | 9.42 |

Use these results to calculate the stress and strain at the yield point, the ultimate strength point, and the fracture point.

**Express your answers to three significant figures.**

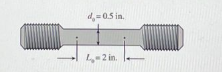

Transcribed Image Text:**Tensile Test Specimen**

**Diagram Explanation:**

The diagram on the left shows a steel tensile test specimen with defined dimensions. The specimen has a central cylindrical section with threads at both ends.

- **Central Section Diameter (\(d_o\))**: 0.5 inches

- **Gauge Length (\(L_o\))**: 2 inches

These parameters measure the deformation and strength of the specimen under tensile loading.

**Text Explanation:**

On the right, there's a table recording the results from a tensile test on the steel specimen. This table outlines the elongation measurements in inches at various applied loads in pounds (P).

**Load and Elongation Table**:

| \(P\) (lb) | \(l\) (in) |

|------------|-------------|

| 0 | 2.0021 |

| 3,551 | 2.0070 |

| 7,091 | 2.0350 |

| 8,882 | 2.0789 |

| 9,724 | 2.1931 |

| 10,197 | 2.2804 |

| 2,264 | 2.4774 |

| 2,579 | 2.5919 |

| 2,657 | 2.7081 |

| 2,728 | 2.7647 |

These data points enable the calculation of stress and strain at critical points, such as the yield point, ultimate strength point, and fracture point of the specimen.

Expert Solution

arrow_forward

Step 1: Determine the given data

The diameter is

Step by stepSolved in 5 steps with 19 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Rotate the objects shown below by the indicated amount and sketch the result in the space provided. You do not need to include the coordinate axes in your sketch.arrow_forwardThe vertical distance above a reference datum to a point is called the point’sarrow_forward20 30 40. -30 100- Draw the three projections of the following figure 60arrow_forward

- Round off answer to 4 decimal placesarrow_forwardUse Share Sketch to create this part with one sketch. Pivot lock (dimensions are in inches. The circular features in the design are all aligned to the two centers at the base.arrow_forwardMake an orthographic projection based on the drawingarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY