Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Topic Video

Question

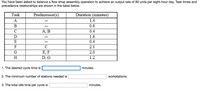

Transcribed Image Text:You have been asked to balance a flow shop assembly operation to achieve an output rate of 80 units per eight-hour day. Task times and

precedence relationships are shown in the table below.

Task

Predecessor(s)

Duration (minutes)

A

1.4

--

В

0.8

--

C

A, B

0.4

1.8

E

0.4

--

F

C

2.1

G

E, F

2.0

H

D, G

1.2

1. The desired cycle time is

minutes.

2. The minimum number of stations needed is

workstations.

3. The total idle time per cycle is

minutes.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 7 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- No written by hand solution and no imagearrow_forwardThe table below shows the time for each work element in an manual assembly process, along with the predecessor(s) required for each element. The ideal cycle time is 1.4 minutes, the repositioning time is 0.1 minutes, and there is one worker at each station. Work element A B C D E F G H I J Time (minutes) 0.7 0.4 0.2 0.3 0.5 0.4 0.6 0.5 0.3 0.2 Immediate predecessors - A A B B C E,F D,E G,H I 1. Using the ranked positional weights method, assign work elements to stations.arrow_forwardWhat is the required workstation cycle time to meet the desired output rate, and how can you balance this line using the longest task time (filling in the chart below)? Note: Leave no cells blank - be certain to enter "0" wherever required.arrow_forward

- True or False: In the Theory of Constraints (TOC), the primary goal is to optimize individual processes within an organization rather than focusing on the overall system's performance.arrow_forwardHi! I need a little help with D. I can't figure out how to calculate the efficiency. Can you explain it to me?arrow_forward2arrow_forward

- Analyze bottleneck resources and apply TOC principles to controlling a process.arrow_forwardHi, I need help solving the remainder of this Operations Management problem. Thank you! *Notes: - The correct answer to part B is also known, "66.8" - "13.4" and "13.5" were both attempted for part C and are not the correct answersarrow_forwardPlease draw a process map using the table I'm struggling on it!arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.