Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

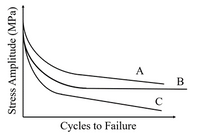

Use the fatigue curves below to answer the following questions.:

Which curve represents a sample subjected to fatigue at the lowest mean tensile stress? (Select One)

Group of answer choices

Curve A

Curve B

Curve C

Transcribed Image Text:A

B

C

Cycles to Failure

Stress Amplitude (MPa)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Draw a typical stress vs strain tensile test curve for the following material and label the axis. A typical brittle material subjected to a tensile stress that has been applied to the material till the sample breaks. 1- label the axis and draw the curve for a brittle material. 2- indicate the maximum strength of the material. 3- show on the portion of the curve where young's modulus can be calculated.arrow_forwardNeed help on this Qarrow_forward1. For the stress-strain curve shown below, please estimate the properties indicated. (a) Fracture Strain Please do your work on a separate sheet of paper, and put your answers in the boxes on the right. Be sure to include the proper symbol and units. Stress Strain 70 60 50 Stress (ksi) 240 30 20 10 70 0 0.000 60 50 Stress (ksi) 40 20 10 KULL 0 0.000 0.010 0.050 0.100 Strain (in/in) Stress Strain 0.020 0.030 Strain (in/in) 0.040 0.150 0.050 (b) Ultimate Tensile Stress (c) Fracture Stress (d) Proportional Limit (e) Elastic Modulus (1) Yield Stress (g) Tensile Toughness (Modulus of Toughness) (h) Modulus of Resiliencearrow_forward

- You have been given the following test sample data following mechanical testing of 15 test pieces of Silicon Nitride. What is the Weibull modulus of this material? Would you advise the use of a similar material with a Weibull Modulus of 16.3 and a mean failure stress of 485 MPa, if you anticipate that the peak stress on the material could be 430 MPa? Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Select one or more: O a. No O b. 18.6 O C. 13.4 O d. Yes O e. 15.7 f. 17.1 Failure Stress (MPa) 423 459 496 432 447 467 473 499 485 479 505 530 526 490 510 <arrow_forwardHow did temperature affect the toughness of the specimens?arrow_forwardThe answer is one of the options below please solve carefully and circle the correct option Please write clear .arrow_forward

- Question 5: Following is tabulated data that were gathered from a series of Charpy impact tests on a tempered 4140 steel alloy. Temperature (°C) 100 75 50 25 0 -25 -50 -65 -75 -85 -100 -125 -150 -175 Impact Energy (J) 89.3 88.6 87.6 85.4 82.9 78.9 73.1 66.0 59.3 47.9 34.3 29.3 27.1 25.0 (a) Plot the data as impact energy versus temperature. (you can use Excel or other software). (b) Determine a ductile-to-brittle transition temperature as that temperature corresponding to the average of the maximum and minimum impact energies. (c) Determine a ductile-to-brittle transition temperature as that temperature at which the impact energy is 70 J.arrow_forwardUse the fatigue curves below to answer the following questions.: Which curve(s) represent(s) a non-ferrous metal? (Select all that apply) Group of answer choices Curve B Curve A Curve Carrow_forward3. A cylindrical specimen of cold-worked copper has a ductility, %EL. If its cold-worked radius is d, what was its radius before deformation? Use %EL=25%; d = 10mm Ductility (%EL) 70 60 50 40 30 20 Brass 1040 Steel 10 Copper 0 0 10 110 20 30 40 50 60 70 Percent cold workarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY