Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

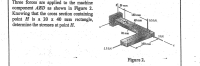

Transcribed Image Text:Three forces are applied to the machine

component ABD as shown in Figure 2.

Knowing that the cross section containing

point H is a 20 x 40 mm rectangle,

determine the stresses at point H.

Y 50 mm

150 mm

40 mm

0.5 kN

20, mm

3 kN

160 mm

2.5 kN

Figure 2.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Two vertical forces, each of magnitude P = 22 kips, are applied to a beam of the cross section shown. Determine the maximum tensile and compressive stresses in portion BC of the beam. The maximum tensile stress is ksi. The maximum compressive stress is ksi.arrow_forwardThe strain rosette shown was used to obtain normal strain data at a point on the free surface of a machine component. Given the values = -165 µμe, e = -155 μe, e = 50 μe, E = 10,600 ksi, and v=0.33, determine (a) the stress components o,,o,, and ry at the point. (b) the principal stresses and the maximum in-plane shear stress at the point; on paper, show these stresses on an appropriate sketch that indicates the orientation of the principal planes and the planes of maximum in-plane shear stress. (c) the magnitude of the absolute maximum shear stress at the point. 45° 45°arrow_forward2) A 150 lb horizontal force, P, is applied to end D of handle ABD in the direction shown. Section AB has a diameter of 1.2 in. a. Determine the stress state at point H (H has sides parallel to the x and y axes). b. Draw a Mohr's circle representation for the point. What are the principal stresses at point H. 10 in. 4 in. y B 18 in. 1.2 in. P xarrow_forward

- 1500 mm²) The assembly shown below consists of a steel (Es = 200 GPa and As tube AB and a brass (EB = 100 GPa and AB 2000 mm²) tube BC. The supports at A and C and the plate at B used to apply the 400 kN load are rigid. Prior to the load being applied, the tubes are stress-free. When the load is applied, determine (a) The normal stresses in each tube. (b) The deflection of the rigid plate at B. XXXXXXXXXX A k 200 kN- Steel 200 kN- 1.5 m B Brass | 1 ·1m → =arrow_forwardTwo forces P1 and P2, with a magnitude of P1 = 15 kN and P2 = 18 kN, are applied as shown in Figure below to the end A of bar AB, which is welded to a cylindrical member BD of radius c = 20 mm. Knowing that the distance from A to the axis of member BD is a = 50 mm and assuming that all stresses remain below the proportional limit of the material, determine the normal and shearing stresses at points H and K of the transverse section of member BD located at a distance b = 60 mm from end B,arrow_forwardPravinbhaiarrow_forward

- Determine the average normal stress developed at points A, B, and C. The diameter of each segment is indicated in the figure.arrow_forwardAll of the parts, please. Thanks!arrow_forwardDetermine the principal stresses at points A and B of the cylinder. Consider: L = 70 mm; d = 20 mm; F = 12 kN; P = 15 kN; T = 800 Nm.arrow_forward

- Please correct solutionarrow_forwardEx. 5.3 At a point in the structural member, the stresses are represented as shown below. Employ Mohr's circle to determine (a) the magnitude and orientation of the principal stresses and (b) the magnitude and orientation of the maximum shear stress and associated normal stresses. In each case, show the results on a properly oriented element. Sol. YA 40 MPa 30 MPa 80 MPaarrow_forwardParvinbhaiarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY