Structural Analysis

6th Edition

ISBN: 9781337630931

Author: KASSIMALI, Aslam.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

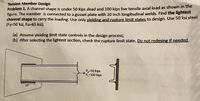

Transcribed Image Text:Tension Member Design

Problem 1. A channel shape is under 50 kips dead and 100 kips live tensile axial load as shown in the

figure. The member is connected to a gusset plate with 10 inch longitudinal welds. Find the lightest

channel shape to carry the loading. Use only vielding and rupture limit states to design. Use 50 ksi steel

(Fy=50 ksi, Fu=65 ksi).

(a) Assume yielding limit state controls in the design process;

(b) After selecting the lightest section, check the rupture limit state. Do not redesing if needed.

1

Pa=50 kips

PL=100 kips

10"

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- A single plate tension member (200 mm x 10 mm) is made of 300W Steel. The member is connected through welded connection as shown. Calculate the total effective net area for shear lag Ane of the tension member. Gusset Plate 300 mm -Weld Tension Member Trarrow_forwardThe torque (C) to be transmitted by a drive at the welds is 650 Nm. Knowing that the diameter of the shaft is 40 mm and the constraint of allowable shear in the welded joint is 55 MPa. a) calculate the tangential force b) calculate the thickness of the weld.arrow_forwardSituation 4: The lap splice shown will develop a full strength as shown in the figure. Using E70 electrodes. The width of the plate is 50 mm and the thickness is 12 mm. Use Fy = 248 MPa T+ T4 O 29 mm O 30 mm 1. Which of the following nearly gives the diameter of the slot weld using the LRFD method. O 27 mm E70 O 28 mm T Tarrow_forward

- The single shear connection consists of six 26-mm-diameter bolts. If the ultimage strength of the bolts is 720 MPa, determine the factor of safety for the connection at an applied load of P= 570 kN. P=570 kNarrow_forwardDesign an unequal angle section to serve as a tie member of 1.6 m length in a roof truss. It has to carry an axial load of 118 kN. The gusset plate is connected to the longer leg of the angle. Also design the fillet weld. Permissible stress in weld = 108 N/mm² Permissible stress in axial tension = 150N / m * m ^ 2 Thickness (t), sectional area (A), weight/m run (w), distance of centres of gravity along x-axis and y-axis. cx and cy maximum and minimum radius of gyration f max and r min are given for some angles for design.arrow_forwardA C130x10 tension member is welded to a plate as shown in the figure. The channel is of Grade 350W steel. The channel is welded on both sides with 110 mm long fillet weld. Assume the weld does not govern the capacity, calculate the factored tension resistance of the channel. The tension resistance is not governed by the plate. C130 XI0arrow_forward

- The welded frame beam connection consists of the framing angle 100 x 75 x12.5mm and the column W12 x 72. The welds are 9mm fillet welds made with E70 electrodes. All members are A36 steel. 12.5 mm a.) Determine Pu base on the capacity of the welds. Use LRFD design Factors. W 12x72 Angular Section 75 m 18.75 18.75 Angular section Angular section 800arrow_forwardPlease Use LRFD * ASD!arrow_forward3) will upvote anyone who will answerarrow_forward

- Using SMAW process, E70 electrodes and an A572 steel. Determine thelength of the side fillet welds for the full capacity the 125x100x10mm angle tensionmember as shown below. Assume that the member is subjected to repeatedstress variations making any connection eccentricity undesirable. Check theblock shear strength of the member. Assume that the WT chord has sufficientstrength to develop the weld strengths and the thickness of its web is 12mm. UseU = 0.87 for class use and LRFD Method only.arrow_forwardThe truss below is pin connected at A and E, and is acted on by the forces shown. E A D B Identify all of the ZERO-FORCE MEMBERS by checking the boxes below (if there are none, leave all boxes unchecked): BF AF BC BH CD EG -GH AB CH DG DH DE -FHarrow_forwardFive M20 8.8/ bolts are used in the connection between a beam and a column. Both sides of the cleat plate are welded to column using fillet weld (Manual metal arc AS4855 B-E43XX) with size of 5 mm. The design force transferred from beam to column is 300 kN. The cleat plate has thickness of 12 mm, fy = 300 MPa, and fü = 360 MPa. Determine the unit stress sustained by the weldarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON

Structural Analysis (10th Edition)Civil EngineeringISBN:9780134610672Author:Russell C. HibbelerPublisher:PEARSON Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Fundamentals of Structural AnalysisCivil EngineeringISBN:9780073398006Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel LanningPublisher:McGraw-Hill Education

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Structural Analysis (10th Edition)

Civil Engineering

ISBN:9780134610672

Author:Russell C. Hibbeler

Publisher:PEARSON

Principles of Foundation Engineering (MindTap Cou...

Civil Engineering

ISBN:9781337705028

Author:Braja M. Das, Nagaratnam Sivakugan

Publisher:Cengage Learning

Fundamentals of Structural Analysis

Civil Engineering

ISBN:9780073398006

Author:Kenneth M. Leet Emeritus, Chia-Ming Uang, Joel Lanning

Publisher:McGraw-Hill Education

Traffic and Highway Engineering

Civil Engineering

ISBN:9781305156241

Author:Garber, Nicholas J.

Publisher:Cengage Learning