Steel Design (Activate Learning with these NEW titles from Engineering!)

6th Edition

ISBN: 9781337094740

Author: Segui, William T.

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Question

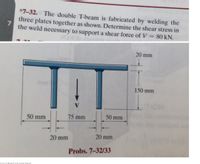

Transcribed Image Text:*7-32.d The double T-beam is fabricated by welding the

three plates together as shown. Determine the shear stress in

the weld necessary to support a shear force of V 80 kN.

20 mm

150 mm

TION

50 mm

75 mm

50 mm

20 mm

20 mm

Probs. 7-32/33

anscribed image text

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- Please answer on the attached imagearrow_forwardS Example 8.7 An ISA 200x100x10 angle LO 3 is welded to a steel plate by means of fillet welds as shown in Fig. 8.17. The angle is subjected to a static force of 150 kN and the permissible shear stress for the weld is 70 N/mm². Determine the lengths of weld at the top and bottom. 1₁ 150 kN TAILL Y2 200 12 - IG 100- 12 71.8 150 KN -10arrow_forwardDetermine the design tensile strength of plate (200x8 mm) connected to 10-mm thick gusset using 20 mm bolts as shown in the figure, if the yield and the ultimate stress of the steel used are 250 MPa and 410 MPa, respectively. Add 1mm around the bolt for the hole. Use LRFD method. Plate 8-mm thick 2 3 40+ 30 301 T 200 mm Gusset 10-mm thick 3af 30 2_3 *40 40+ 50,54 +40arrow_forward

- The following image shows a front and side view of the column connection. The bolts have a diameter of ¾”. The W12X65 profile has a thickness of 0.605”. Determine:a. The shear stress in the bolts.b. The axial stress in the bolts.c. The support stress in the W12X65 profile.arrow_forwardPlease answer the problem attached image.(using Nscp 2015) thank youarrow_forward*12-32. The double T-beam is fabricated by welding the three plates together as shown. Determine the shear stress in the weld necessary to support a shear farce af V = 80 kN 20 mm 150 mm So mm 75 mm So mm 20 mm 20 mmarrow_forward

- A 100 x 100 x 10 mm angle is to be welded to a gusset plate. The angle carries a load of 200 kN applied along its centroidal axis which is 28.7 mm above the short leg as shown in the figure. Use an 8 mm fillet weld with a minimum tensile strength Fu = 483.33 MPa. Determine the length of a transverse fillet weld along the edge of the angle in order to avoid eccentricity of loading. Determine the length of side fillet weld required at the heel. Determine the length of side fillet weld required at the toe.arrow_forwardA tie member of a roof truss consists of 21SA 100 x 75 x 8 mm. The angles are connected by fillet weld as shown in figure on either side of a 10 mm gusset plate and the member is subjected to a factored pull of 450 kN. Take size of weld as 6 mm and connections are made in workshop. [Use Fe410 grade of steel] 75 m L. C. = 31mm 16A (100 x 75 x 8) mm Choose the nearest correct statements: L1 = 390.5 mm L1 = 195.25 mm Correct Option L2 = 87.75 mm Correct Option L2 = 175.5 mmarrow_forwardThe 1 x 6 plate shown in Fig. 3.13 is connected to a 1 x 10 in plate with longitudinal fillet welds to transfer a tensile load. Determine the LRFD design tensile strength and the ASD allowable tensile strength of the member if Fy = 50 ksi and Fu = 65 ksi.arrow_forward

- A plate is connected to the column using fillet welds as shown. The size of weld is 8 mm. Determine the following: a. Shear stress due to load alone b. Shear stress due to moment c. Maximum shear stress.arrow_forward* A 76 mm x 76mm x 6mm angular section is welded to a gusset plate having a thickness of 8mm as shown in the figure. The length L1 equals 125mm and L2 is 65mm. The angular section has a cross sectional area of 929mm2, Fy=248 MPa, Fu=400MPa. Determine the value of tensile force P based on block shear in gusset plate along the weld in kN. Allowable stresses: Allowable tensile stress (gross area) = 0.6Fy Allowable tensile stress (net area) = 0.50Fu Allowable shear stress (net area) = 0.30Fu P gusset plate L₂= 65 mm 25 mmarrow_forwardA76 x 76 x6 mm angular section shown is welded to an 8 mm thick gusset plate. The length L1 is 65 mm, L2 is 125 mm, and the cross sectional area of the angle is 929 sq.mm. Fy-248MPA and Fu -400MPA. Gusset Plate Alowable Sresse Alowable tensle stress igross ara)0.00 Alowable tereile stres net area)0SOF. Allowable shear stress (net ares)0.30F. Determine the value of P based on net area using a strength reduction coefficient of 85% O 138.24 KN O 140.14 kN O 157.93 kN O 304.00 N Nextarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...

Civil Engineering

ISBN:9781337094740

Author:Segui, William T.

Publisher:Cengage Learning