Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

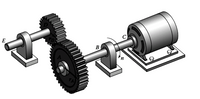

The input shaft to a gearbox, shown in Figure 3, operates at a speed of n1 and

transmits a power of 30 hp. The output power is 27 hp at a speed of n2. (a) What

is the torque of each shaft (in kip · in.) and (b) the efficiency of the gearbox?

Use n1 = 1800 rpm, n2 = 425 rpm. (c) Also compute for the torsional stress on

the 1.5” diameter solid shaft C, and on the hollow shaft at E whose D =2”

and d = 1.5”.

Transcribed Image Text:B

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Like will be given :)arrow_forwardA motor supplies 173 hp at 650 rpm to flange A of the shaft. Gear B transfers 75 hp of power to operating machinery in the factory, and the remaining power in the shaft is transferred by gear D. Shafts (1) and (2) are solid aluminum [G = 4400 ksi] shafts that have the same diameter and an allowable shear stress of T = 5.8 ksi. Shaft (3) is a solid steel [G=9100 ksi] shaft with an allowable shear stress of T = 10.2 ksi. Assume that L₁=2.3 ft, L₂=1.2 ft, L3-2.9 ft. Determine: (a) the minimum permissible diameter d₁=d₂ for aluminum shafts (1) and (2). (b) the minimum permissible diameter d3 for steel shaft (3). (c) the rotation angle D/A of gear D with respect to flange A if the shafts have the minimum permissible diameters as determined in (a) and (b). Answers: (a) d₁=d₂ = i (b) d3= i (c) & DIA = i (1) L₁ TB. B (2) L2 in. in. o' (3) L3 Tp Mommu Darrow_forwardSpur gear train is used to transmit the power of 2kW from input gear A rotating at 120 rpm to output gear D through a compound gear BC. The number of teeth on the gear A, B, C and D are 16, 32, 12 and 18 respectively. Given: Module = 4mm, pressure angle=20° The tangential force acting on the gear B is N A D Вarrow_forward

- Parvinbhaiarrow_forwardThe shaft shown in the figure is machined from AISI 1040 CD steel. The shaft rotates at 1600 rpm and is supported in rolling bearings at A and B. The applied forces are F₁ = 1600 lbf and F2 = 640 lbf. A steady torque of 1600 lbf-in is being transmitted through the shaft between the points of application of the forces. 1 / in ] A in [lin -10 in- F₁ in F₂ -10 in- All fillets in R. 12in] 3 in The value of the notch sensitivity is The value of the fatigue stress concentration factor is in NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. What is the value of the theoretical stress concentration factor for torsion, the notch sensitivity, and the fatigue stress concentration factor? (You must provide an answer before moving to the next part.) The value of the theoretical stress concentration factor for torsion isarrow_forwardGear shaft ABCDE is subjected to the torques shown in the figure. Find the internal torque in each seg- ment, and then plot the torsional moment diagram. Assume that the spacing between gears is constant, i.e., 10 in. T1 = T2 = 1000 lb-in. 500 lb-in. A B T3 = 800 Ib-in. C Ta = 500 lb-in. d = 1.0 in. D T; = 800 lb-in. Earrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY