MATLAB: An Introduction with Applications

6th Edition

ISBN: 9781119256830

Author: Amos Gilat

Publisher: John Wiley & Sons Inc

expand_more

expand_more

format_list_bulleted

Concept explainers

Topic Video

Question

Transcribed Image Text:The following are quality control data for a manufacturing process at Kensport Chemical Company. The data show the temperature in degrees centigrade at five points in time during a manufacturing cycle.

Sample

R

1

95.72

1.0

2

95.24

0.9

3

95.18

0.7

4

95.42

0.4

95.46

0.5

6

95.32

1.1

7

95.40

0.9

8

95.44

0.3

95.08

0.2

10

95.50

0.6

11

95.80

0.6

12

95.22

0.2

13

95.54

1.3

14

95.22

0.6

15

95.04

0.8

16

95.72

1.1

17

94.82

0.6

18

95.46

0.5

19

95.60

0.4

20

95.74

0.6

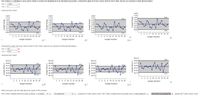

The company is interested in using control charts to monitor the temperature of its manufacturing process. Compute the upper and lower control limits for the R chart. (Round your answers to three decimal places.)

Transcribed Image Text:The company is interested in using control charts to monitor the temperature of its manufacturing process. Compute the upper and lower control limits for the R chart. (Round your answers to three decimal places.)

UCL =

1.4058

LCL = 0

Construct the R chart.

2.00-

1.75

2.00-

1.75-

잃o 1.50

2.00-

2.00-

1.75-

1.50-

1.75

1.50

UCL

UCL

% 1.50-

1.25

UCL

1.00

1.25

1.00-

0.75

1.25

1.25

UCL

0.75

1.00

1.00

0.50

0.75

0.75

0.50

0.25

0.50

E 0.25

0.50

0.00

0.25

0.25

LCL

0.00

0.00-

LCL

0.00

LCL.

LCL

2 4 6 8 10 12 14 16 18 20

2 4 6 8 10 12 14 16 18 20

2 4 6 8 10 12 14 16 18 20

2 4 6 8 10 12 14 16 18 20

Sample Number

Sample Number

Sample Number

Sample Number

Compute the upper and lower control limits for the x chart. (Round your answers to three decimal places.)

UCL = 95.7

LCL - 95.09

Construct the x chart.

96.25+

UCL

96.25+

96.25

96.25

* 96.00

96.00

96.00

96.00

95.75

UCL

UCL

95.75

95.75

95.75

UCI

95.50-

95.50

95.50

95.50

95.25

95.25

95.25

95.25-

95.00-

95.00

95.00

95.00

LCL

94.75

LCL

LCL

LCL

94.75

94.75-

94.75

2 4 6 8 10 12 14 16 18 20

2 4 6 8 10 12 14 16 18 20

2 4 6 8 10 12 14 16 18 20

2 4 6 8 10 12 14 16 18 20

Sample Number

Sample Number

Sample Number

Sample Number

What conclusions can be made about the quality of the process?

The R chart indicates that the process variability is (in control

No samples fall|

vy outside the R chart control limits. The x chart indicates that the process mean is out of control v

More than two samples fall x outside the x chart control limits.

Sample Mean X

Sample Range

Sample Mean x

Sample Range

Sample Mean X

sample Mean X

Sample Range

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, statistics and related others by exploring similar questions and additional content below.Similar questions

- help with 4! please i don’t understand..arrow_forwardCan a low barometer reading be used to predict maximum wind speed of an approaching tropical cydone? For a random sample of tropical cyclones, let x be the lowest pressure (in millibars) as a cyclone approaches, and let y be the maximum wind speed (in miles per hour) of the cyclone. x 1004 975 992 935 971 924 y 40 100 65 145 78 147 A USE SALT (a) Make a scatter diagram ofr the data and visualize the line you think best fits the data. * 140 1000 140 1000 120- 120 100 100 80 80 940 60 940 E 60 40 40e. 920li 40 920 40 60 80 100 120 140 940 960 980 1000 60 80 100 120 140 940 960 980 1000 x (lowest pressure (in millibars) x (lowest pressure (in millibars) x (lowest pressure (in millibars)) x (lowest pressure (in millibars) (b) Would you say the correlation is low, moderate, or strong? O low O moderate O strong Would you say the correlation is positive or negative? O positive O negative (C) Use a calculator to verity thatx - 5801, - 5,613,547, E- 575, E- 64,543 and xy - 549,281. Compute r.…arrow_forwardplease provide correct answers and a good format table.I will also attach some pictures how the table should be.arrow_forward

- Q19 determine whether the given value is a statistic or a parameter. A homeowner measured the voltage supplied to his home on all 7 days of a given week, and the average ( mean ) value is 126.3 volts. choose the correct answer below . A. The given value is a parameter for the week because the data collected respresent a population. b. The given value is a parameter for the week because the data collected represent a sample. c. The given value is a statistic for the week because the data collected represent a population. d. The given value is a statistic for the week because the data collected represent a sample.arrow_forwardHi. PLease note I already asked this question and received the wrong answer. Jobs and productivity! How do retail stores rate? One way to answer this question is to examine annual profits per employee. The following data give annual profits per employee (in units of 1 thousand dollars per employee) for companies in retail sales. Assume σ ≈ 3.6 thousand dollars. 3.9 6.5 4.5 8.7 7.5 5.2 8.3 5.9 2.6 2.9 8.1 −1.9 11.9 8.2 6.4 4.7 5.5 4.8 3.0 4.3 −6.0 1.5 2.9 4.8 −1.7 9.4 5.5 5.8 4.7 6.2 15.0 4.1 3.7 5.1 4.2 (a) Use a calculator or appropriate computer software to find x for the preceding data. (Round your answer to two decimal places.) thousand dollars per employee(b) Let us say that the preceding data are representative of the entire sector of retail sales companies. Find an 80% confidence interval for μ, the average annual profit per employee for retail sales. (Round your answers to two decimal places.)…arrow_forwardOL th.. Frequency 8 9 0 T 10 20 30 40 LEAD 50 60 70 80 Data were collected on the lead levels of children of battery factory workers. The data are displayed in the histogram above. Choose the correct answer. The maximum lead level is less than 60 The median lead level (the level that exactly half the children exceed) is less than 30 There are 33 children in the data set. None of the other answers is truearrow_forward

- Find the indicated z-scores shown in the graph. Click to view page 1 of the table. Click to view page 2 of the table. 0.0244 0.0244 X z=? z=? ... The z-scores are (Use a comma to separate answers as needed. Round to two decimal places as needed.)arrow_forwarddetermine the two values of z such that the middle 50% of the data lie between the two z values. round the solutions to two decimal places , if necessary. The middle 50% of the data lie between z=___ and z=___.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

MATLAB: An Introduction with ApplicationsStatisticsISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc

MATLAB: An Introduction with ApplicationsStatisticsISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc Probability and Statistics for Engineering and th...StatisticsISBN:9781305251809Author:Jay L. DevorePublisher:Cengage Learning

Probability and Statistics for Engineering and th...StatisticsISBN:9781305251809Author:Jay L. DevorePublisher:Cengage Learning Statistics for The Behavioral Sciences (MindTap C...StatisticsISBN:9781305504912Author:Frederick J Gravetter, Larry B. WallnauPublisher:Cengage Learning

Statistics for The Behavioral Sciences (MindTap C...StatisticsISBN:9781305504912Author:Frederick J Gravetter, Larry B. WallnauPublisher:Cengage Learning Elementary Statistics: Picturing the World (7th E...StatisticsISBN:9780134683416Author:Ron Larson, Betsy FarberPublisher:PEARSON

Elementary Statistics: Picturing the World (7th E...StatisticsISBN:9780134683416Author:Ron Larson, Betsy FarberPublisher:PEARSON The Basic Practice of StatisticsStatisticsISBN:9781319042578Author:David S. Moore, William I. Notz, Michael A. FlignerPublisher:W. H. Freeman

The Basic Practice of StatisticsStatisticsISBN:9781319042578Author:David S. Moore, William I. Notz, Michael A. FlignerPublisher:W. H. Freeman Introduction to the Practice of StatisticsStatisticsISBN:9781319013387Author:David S. Moore, George P. McCabe, Bruce A. CraigPublisher:W. H. Freeman

Introduction to the Practice of StatisticsStatisticsISBN:9781319013387Author:David S. Moore, George P. McCabe, Bruce A. CraigPublisher:W. H. Freeman

MATLAB: An Introduction with Applications

Statistics

ISBN:9781119256830

Author:Amos Gilat

Publisher:John Wiley & Sons Inc

Probability and Statistics for Engineering and th...

Statistics

ISBN:9781305251809

Author:Jay L. Devore

Publisher:Cengage Learning

Statistics for The Behavioral Sciences (MindTap C...

Statistics

ISBN:9781305504912

Author:Frederick J Gravetter, Larry B. Wallnau

Publisher:Cengage Learning

Elementary Statistics: Picturing the World (7th E...

Statistics

ISBN:9780134683416

Author:Ron Larson, Betsy Farber

Publisher:PEARSON

The Basic Practice of Statistics

Statistics

ISBN:9781319042578

Author:David S. Moore, William I. Notz, Michael A. Fligner

Publisher:W. H. Freeman

Introduction to the Practice of Statistics

Statistics

ISBN:9781319013387

Author:David S. Moore, George P. McCabe, Bruce A. Craig

Publisher:W. H. Freeman