FINANCIAL ACCOUNTING

10th Edition

ISBN: 9781259964947

Author: Libby

Publisher: MCG

expand_more

expand_more

format_list_bulleted

Concept explainers

Topic Video

Question

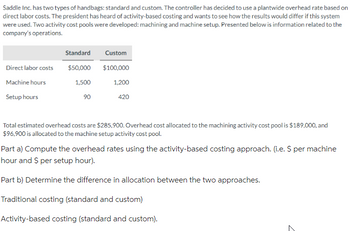

Transcribed Image Text:Saddle Inc. has two types of handbags: standard and custom. The controller has decided to use a plantwide overhead rate based on

direct labor costs. The president has heard of activity-based costing and wants to see how the results would differ if this system

were used. Two activity cost pools were developed: machining and machine setup. Presented below is information related to the

company's operations.

Direct labor costs

Machine hours

Setup hours

Standard

$50,000

1,500

90

Custom

$100,000

1,200

420

Total estimated overhead costs are $285,900. Overhead cost allocated to the machining activity cost pool is $189,000, and

$96,900 is allocated to the machine setup activity cost pool.

Part a) Compute the overhead rates using the activity-based costing approach. (i.e. $ per machine

hour and $ per setup hour).

Part b) Determine the difference in allocation between the two approaches.

Traditional costing (standard and custom)

Activity-based costing (standard and custom).

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Similar questions

- Thermal Rising, Incorporated, makes paragliders for sale through specialty sporting goods stores. The company has a standard paraglider model, but also makes custom-designed paragliders. Management designed an activity-based costing system with the following activity cost pools and activity rates: Activity Cost Pool Supporting direct labor Order processing Custom design processing Customer service Activity Rate $ 20 per direct labor-hour $ 192 per order $ 265 per custom design $ 432 per customer Management wants to calculate the profitability of a particular customer, Big Sky Outfitters, which ordered the following products over the last 12 months: Number of gliders Number of orders Number of custom designs Direct labor-hours per glider Selling price per glider Direct materials cost per glider Standard Model 15 2 0 28.50 $ 1,850 $470 Custom Design 222 34.00 $ 2,480 $ 572 The company's direct labor rate is $18 per hour. Required: Using the company's activity-based costing system,…arrow_forwardSampson Jewelry Corporation manufactures custom jewelry. In the past, Sampson has been using a traditional overhead allocation system based solely on direct labor hours. Sensing that this system was distorting costs and selling prices, Sampson has decided to switch to an activity-based costing system using three activity cost pools. Information on these activity cost pools are as follows: Activity Cost Pool Total Cost Total Activity Labor Related $40,000 8,000 Direct labor hours Machine Related $50,000 12,500 Machine Hours Quality Control $12,000 800 Inspections Sampson has received an order and will complete as Job #309 and expect to incur $900 of direct material, 30 hours of direct labor at $40 per hour, 80 machine hours, and 5 inspections. Sampson needs a markup of 40% on the job.Required:A). Calculate the activity rate and compute is the expected cost of job#309 under the activity-based costing system? What should be the quote on this job?…arrow_forwardBonita, Inc. produces two types of gas grills: a family model and a deluxe model. Bonita's controller has decided to use a plantwide overhead rate based on direct labor costs. The president of the company recently heard of activity-based costing and wants to see how the results would differ if this system were used. Two activity cost pools were developed: machining and machine setup. Presented below is information related to the company's operations: Direct labor costs Machine hours Setup hours (a) Family Model $76,800 2,000 200 Total estimated overhead costs are $460,800. Overhead cost allocated to the machining activity cost pool is $276,480 and $184,320 is allocated to the machine setup activity cost pool. Overhead rate Deluxe Model $153,600 2,000 800 Compute the overhead rate using the traditional (plantwide) approach. (Round answer to 2 decimal places, e.g. 15.25.) $arrow_forward

- Brannon Company manufactures ceiling fans and uses an activity-based costing system. Each ceiling fan consists of 20 separate parts totaling $95 in direct materials, and requires 2.5 hours of machine time to produce. Additional information follows: Cost Pool Allocation Base Overhead Rate Materials handling Number of parts $.08 Machining Machine hours $7.20 Assembling Number of parts $.35 Packaging Number of finished units $2.70 What is the cost of machining per ceiling fan? Brannon Company manufactures ceiling fans and uses an activity-based costing system. Each ceiling fan consists of 20 separate parts totaling $95 in direct materials, and requires 2.5 hours of machine time to produce. Additional information follows: Cost Pool Allocation Base Overhead Rate Materials handling Number of parts $.08 Machining Machine hours $7.20 Assembling Number of parts $.35 Packaging Number of finished units $2.70 What is the cost of machining per ceiling fan? $144.00 $18.00 $180.00 $30.00arrow_forward. The company has traditionally used a plantwide manufacturing overhead rate based on machine hours to allocate manufacturing overhead to its products. The company estimates that it will incur screenshots attached thanks for help appreciataed irwgoirhw rhjiwarrow_forwardFountain Water Products (FWP) manufacturers water bottles. They have historically used a traditional system that allocated the manufacturing overhead costs based on machine hours. FWP is looking at switching to an ABC system in order to ensure more accurate product costing. They first want to compare the traditional and ABC costing systems to determine if it is worth the effort and costs to implement and maintain. They estimate a total overhead cost of $459,000. Under the traditional system they identified machine hours as the cost driver, and estimated a total of 51,000 machine hours. They actually incurred 48,700 machine hours in production. The total applied MOH calculated under the more precise ABC system was $320,000. The ABC costing system will cost $50,000 to implement. FWP has determined that a benefit of more accurate costing by $80,000 is worth the $50,000 implementation cost. What is the difference between the ABC costing and traditional system? Enter your number as a…arrow_forward

- Thermal Rising, Incorporated, makes paragliders for sale through specialty sporting goods stores. The company has a standard paraglider model, but also makes custom-designed paragliders. Management designed an activity-based costing system with the following activity cost pools and activity rates: Activity Cost Pool Supporting direct labor Order processing Custom design processing Customer service Activity Rate $ 18 per direct labor-hour $ 200 per order $ 264 per custom design $ 432 per customer Management wants to calculate the profitability of a particular customer, Big Sky Outfitters, which ordered the following products over the last 12 months: Number of gliders Number of orders Number of custom designs Direct labor-hours per glider Selling price per glider Direct materials cost per glider Standard Model Custom Design 15 2 2 2 0 2 30.50 34.00 $ 1,850 $ 452 $ 2,480 $ 582 The company's direct labor rate is $20 per hour. Required: Using the company's activity-based costing system,…arrow_forwardJulio produces two types of calculator, standard and deluxe. The company is currently using a traditional costing system with machine hours as the cost driver but is considering a move to activity-based costing. In preparing for the possible switch, Julio has identified two cost pools: materials handling and setup. The collected data follow: Standard Model Deluxe Model Number of machine hours 25,800 30,800 Number of material moves Number of setups 590 890 70 540 Total estimated overhead costs are $347,100, of which $170,200 is assigned to the material handling cost pool and $176,900 is assigned to the setup cost pool. Required: 1. Calculate the overhead assigned to each product using the traditional cost system. 2. Calculate the overhead assigned to each product using ABC.arrow_forwardMaxey & Sons manufactures two types of storage cabinets—Type A and Type B—and applies manufacturing overhead to all units at the rate of $120 per machine hour. Production information follows. Type A Type BAnticipated volume (units) 24,000 45,000 Direct-material cost per unit $ 28 $ 42 Direct-labor cost per unit 33 33 The controller, who is studying the use of activity-based costing, has determined that the firm’s overhead can be identified with three activities: manufacturing setups, machine processing, and product shipping. Data on the number of setups, machine hours, and outgoing shipments, which are the activities’ three respective cost drivers, follow. Type A Type B TotalSetups 140 100 240 Machine hours 48,000 67,500 115,500 Outgoing shipments 200 150 350 The firm’s total…arrow_forward

- Reynoso Corporation manufactures titanium and aluminum tennis racquets. Reynoso’s total overhead costs consist of assembly costs and inspection costs. The following information is available: Cost Titanium Aluminum Total Cost Assembly 500 mach. hours 500 mach. hours $27000 Inspections 350 150 $80000 2100 labor hours 1900 labor hours Reynoso is considering switching from one overhead rate based on labor hours to activity-based costing.Using activity-based costing, how much inspections cost is assigned to titanium racquets? $24000. $40000. $56000. $29000.arrow_forwardCrmration manufactures bwo models of office chairs, a standard and a deluxe model. The following activity and cost information has been compiled: Number of Number of Number of Setups Components Direct Labor Hours 10 290 Preduct Standard 13 18 235 32 Delue $72,000 $95,200 Overhead costs Amnealraditional costing system applies the overhead costs based on direct labor hours. What is the total amount of overhead costs assigned to the standard model? (Do not round interim calculations. Round the final anewes ln the a whole dollar) OA S92.358 OB $74,842 OC $83,600 OD. $52.587 O Time Remaining: 01:46:06 Next % 5 6. 7. 8. ఉం W R Y 314arrow_forwardNichols Inc. manufactures remote controls. Currently the company uses a plant- wide rate for allocating manufacturing overhead. The plant manager believes it is time to refine the method of cost allocation and has the accounting department identify the primary production activities and their cost drivers: Activities Material handling Assembly Inspection Cost driver Number of parts Labour hours Time at inspection station The current traditional cost method allocates overhead based on direct manufacturing abour hours using a rate of £200 per labour hour. a. b. Allocation Rate £2 per part £20 per hour £3 per minute What are the indirect manufacturing costs per remote control assuming an activity- based-costing method is used and a batch of 50 remote controls are produced? The batch requires 100 parts, 6 direct manufacturing labour hours, and 2.5 minutes of inspection time. £4.00 per remote control £6.55 per remote control £24.00 per remote control £327.50 per remote control C. d.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning,

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning, Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning,

Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning, Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON

Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education

Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Accounting

Accounting

ISBN:9781337272094

Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.

Publisher:Cengage Learning,

Accounting Information Systems

Accounting

ISBN:9781337619202

Author:Hall, James A.

Publisher:Cengage Learning,

Horngren's Cost Accounting: A Managerial Emphasis...

Accounting

ISBN:9780134475585

Author:Srikant M. Datar, Madhav V. Rajan

Publisher:PEARSON

Intermediate Accounting

Accounting

ISBN:9781259722660

Author:J. David Spiceland, Mark W. Nelson, Wayne M Thomas

Publisher:McGraw-Hill Education

Financial and Managerial Accounting

Accounting

ISBN:9781259726705

Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting Principles

Publisher:McGraw-Hill Education