Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Transcribed Image Text:QUESTION 1

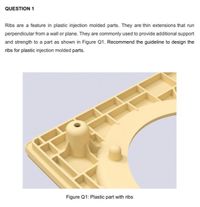

Ribs are a feature in plastic injection molded parts. They are thin extensions that run

perpendicular from a wall or plane. They are commonly used to provide additional support

and strength to a part as shown in Figure Q1. Recommend the guideline to design the

ribs for plastic injection molded parts.

Figure Q1: Plastic part with ribs

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- 3. A dimension of 225.00 mm is specified for a particular injection moulded component manufactured in ABS. Calculate the corresponding dimension to which the mould cavity should be machined, using the value of shrinkage given in the table below. Typical values of shrinkage for moldings of selected thermoplastics. Shrinkage, mm/mm (in/in) Shrinkage, Plastic Plastic mm/mm (in/in) ABS Polyethylene Polystyrene 0.006 0.025 Nylon-6,6 Polycarbonate 0.020 0.004 0.007 PVC 0.005arrow_forwardPlastics may exhibit a change in properties as they age, particularly when subjected to elevated temperatures. Material properties such as tensile strength will increase with an increasing temperature as a function of increasing time. True or false.arrow_forwardPlease solve only problem 3.arrow_forward

- An injection molded polyethylene part has a dimension of 6.25 cm. A new material, polycarbonate, is used in the same mold. What is the expected corresponding dimension of the polycarbonate molding?arrow_forwarda-c explained fully please thanks!arrow_forwardWhich of the following are reasons why injection molding of thermosets is more difficult than injection molding of thermoplastics (two best answers): O allowances must be made for cross-linking of thermosets O barrel temperatures must be hotter for thermosets O cycle times are longer because of curing thermosets are denser O two injection units are requiredarrow_forward

- Define the term perfectly plastic?arrow_forwardQuestion 3 The diameter of an extruder barrel is 65 mm and its length is 1.75 m. The screw rotates at 55 rev/min. The screw channel depth is 5.0 mm, and its flight (helix) angle is 18°. The head pressure at the die end of the barrel is 5x10° Pa. The viscosity of the polymer melt is given as 100 Pa-s. Calculate the volume flow rate of polymer in the barrel. The drag flow is given by the equation: Qa = 0.5 n2 D² N d̟ sinp cosp The back pressure flow is given by the equation: Pn D dễ sin²o Qb 127L The details of the extruder screw are given in figure 3.1 W. Perpendicular channel width Helix angle (O) Pitch Channel depth de Axial |light| width Axial channel width Perpendicular fight -Direction of mass flow- Figure 3.1. Schematic illustration of a typical "Archimedean" extruder screw. width Root diameter diameterarrow_forwardQuestion 3 The diameter of an extruder barrel is 65 mm and its length is 1.75 m. The screw rotates at 55 rev/min. The screw channel depth is 5.0 mm, and its flight (helix) angle is 18°. The head pressure at the die end of the barrel is 5x10° Pa. The viscosity of the polymer melt is given as 100 Pa-s. Calculate the volume flow rate of polymer in the barrel. The drag flow is given by the equation: Qa = 0.5 n² D² N d̟ sinp cosp The back pressure flow is given by the equation: Pn D dễ sin²4 Qb 127L The details of the extruder screw are given in figure 3.1 W. channel width Perpendicular Pitch Helix ( p angle () D Channel depth de |Axial |light| width Axial channel width Perpendicular flight -Direction of mass flow- Figure 3.1. Schematic illustration of a typical "Archimedean" extruder screw. width Root diameter diameterarrow_forward

- As the lead engineer for a LPG storage project, you are overseeing the design of pressure vesselssuch as those shown below. Identify which test (or tests) is mostsuitable to pick a material and thickness for the spherical shell of the pressure vessel. Why these are the relevant tests. Explain what information these tests provide and why it is important to determining material and thickness.arrow_forwardThe figure shown below (Fig. 2) is a schematic representation of a scissor jack in two different positions. The maximum load that this mechanism must withstand is 800 kg. 4 are proposed different materials to make the jack arms and spindle. The mechanical properties and some Physical characteristics of each material are shown in Table 1. a) Based on the properties of each material and the cross section of the arms and the screw, Propose what would be the most suitable material for its manufacture. The length of each arm is 150 mm. The stress on the arms and the spindle must not exceed the yield strength of the material selected for neither of the two analysis positions. b) Using the mechanical properties of the material you selected, calculate the change in dimension that the arms and the spindle of the jack were tested for the two analysis positions. The length of the spindle is 280 mm.arrow_forwardPlease solve accurate and exact answers sir please!! (it must be typed not handwritten) Thanks!!arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY