Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

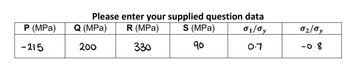

Transcribed Image Text:P (MPa)

-215

Please enter your supplied question data

R (MPa)

S (MPa)

01/0y

330

90

0.7

Q (MPa)

200

02/0y

-0.8

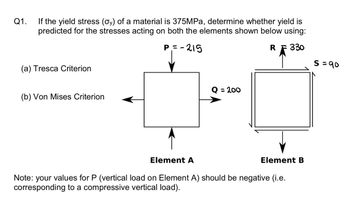

Transcribed Image Text:Q1. If the yield stress (oy) of a material is 375MPa, determine whether yield is

predicted for the stresses acting on both the elements shown below using:

P₁=-215

RF 330

(a) Tresca Criterion

(b) Von Mises Criterion

Q = 200

Element A

Note: your values for P (vertical load on Element A) should be negative (i.e.

corresponding to a compressive vertical load).

Element B

S=90

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 4 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- The stresses on the surface of a hard bronze component are shown in the figure below. The yield strength of the bronze is σY = 345 MPa.a) What is the factor of safety predicted by the maximum-shear-stress theory of failure for the stress state shown? Does the component fail according to this theory?b) What is the value of the Mises equivalent stress for the given state of plane stress?c) What is the factor of safety predicted by the failure criterion of the maximum-distortion energy theory of failure? Does the component fail according to this theory?arrow_forward3) Referring to the plot below, a steel bar with a radius of 0.2523-inch exposes to 650°C. If the expected lifetime of the iron bar is 9 years, what is the maximum load allowed to carry? ( Stress (psi) 20,000 10,000 8,000 6,000 4,000 2,000- 1,000 30 32 34 36 38 40 42 (36+0.78 In s) Larson-Miller parameter w 1000arrow_forwardQ1Barrow_forward

- A stress element is shown. The material has a yield strength of 200 MPa, an ultimate strength of 275 MPa, and a Young’s Modulus of 207 GPa.arrow_forwardmaterial mechanicsarrow_forwardFind the maximum normal stress in the bar pictured below. The parameter values are listed in the table. W2 P parameter value units དྷདྷ་ W1 30 mm W2 40 mm t 5 mm r 10 mm d 20 mm P 8 KN The maximum normal stress is σmax kd MPa. 080 BY NO SA 2021 Cathy Zupke Parrow_forward

- answer as soon as soon as possiblearrow_forwardA steel bolt of 6 mm in diameter has a tensile load of 40 kN. Find the average tensile stress at the section M and the screwed section N, where the diameter at the root of the thread is 2. 4 mm as shown in Figure QI.2. (6) M - 40 kN 40 kN - 4 mm diameter 6 mm diameter Figure Q1.2: Steel boltarrow_forwardQ2/ A force P = 1 KN applied to a right bar suspended by three wires, as shown below. all wires are of equal size and the same material. for each wire, A = 80 mm , E =200 GPa , and L =4 m. If initially, there were no slack in the wires, how will the applied load distribute between the wires? 200 100 100 4000 mm mm mm mmarrow_forward

- D 12KN B A 10KN 28kN + + 60KN 44kN + 120cm 80cm Ост 40cm Figure 1 a) Draw a Free Body Diagram for each section of the member above. b) Determine the force acting on the section BC. c) Draw a Normal Force Diagram for the figure above. d) Calculate the stress induced in the member BC if the diameter of the rod is 55.2791mm. e) Determine the total elongation of the rod.arrow_forwardi li. الامتحان هو سؤالان فقط Q. 1: If a material is cast iron (ultimate tensile strength = 300 Mpa, ultimate compressive strength - 900 Mpa) and the stress state at a point is shown in Fig. 1. Using a graphical method, find safety factor against static failure using 100 Mpa (a) Rankine failure theory (b) Coloumb - Mohr theory (c) Modified Coloumb - Mohr theory 50 Мра إضافة ملف Q.2 For a rotating shaft of diameter 15 mm as shown in Fig. 2. If the material is AISI-1045 CD, Find the safety factor II >arrow_forwardAL: 1₂ The above figure (not drawn to scale) shows a rod made up of two cylindrical sections of the same material. The left cylinder has diameter d, = 30mm and length 4 = 150mm. The right cylinder has diameter dy=10mm and length = 150mm. The rod is subjected to a force F = 50KN. Find the total extension in the rod, AL, given that E = 203kN/mm². Enter your answer in mm to 5 decimal places in the box below: mm -Farrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY