Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

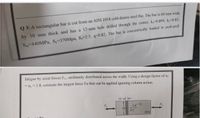

Transcribed Image Text:Q 3\ A rectangular bar is cut from an AISI 1018 cold-drawn steel flat. The bar is 60 mm wide

by 10 mm thick and has a 12-mm hole drilled through the center, k,-0.899, k,=0.85.

Su 440MPA, Sy-370Mpa, K-2.5, q-0.82, The bar is concentrically loaded in push-pull

fatigue by axial forces Fa, uniformly distributed across the width. Using a design factor of nf

= n, = 1.8, estimate the largest force Fa that can be applied ignoring column action.

10- -

12

F.

60

1018

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A bracket is under a loading condition shown below. It's made from a steel with yield strength (Sy) of 42 ksi and ultimate tensile strength (Sut) of 76 ksi. The diameter is 0.42 in and b = 1.75 in, with the load P fluctuate between 15 lbs (tension) and -5 lbs (compression). Using the modified Goodman or Gerber criterion, determine the fatigue factor of safety based on infinite life. If infinite life is not predicted, estimate the number of cycles to failure. Also check for yielding.arrow_forwardRequired information The cold-drawn AISI 1040 steel bar shown in the figure is subjected to an axial load that fluctuates from 8 kN to 30 kN. Use the Modified Goodman criterion and estimate the fatigue factor of safety based on achieving infinite life and the yielding factor of safety. 25 mm 10mm -6-mm D. What is the number of cycles to failure for this part? The number of cycles is 120000arrow_forwardA cylindrical steel bar 8 mm in diameter is loaded 1000 cycles per day with a load of 15560 N. How long until fatigue failure takes place? Note: stress force/area 500 450 400 350 Steel Allby 300 250 200 150 Brass Alloy 100 50 1.00E-07 Cycles to Failure, N 1.00E+04 1.00E+05 1.00E-06 1.00E+08 100E+09 1.00E+10 , The bar should not fatigue. ) The bar will fail in one cycle. ) 100 days ) 1000 days Stress Amplitude, MPaarrow_forward

- 12. An aluminum sleeve is held between the head and the nut of a steel bolt. The temperature is raised 40°F from 60°F after the nut is turned 45° against the sleeve from loose contact therewith. Calculate the stresses in the sleeve and the bolt. BOLT IS 1/2" DIA, 16 THREADS/ IN. E(ALUM.) 10 x 106 psi E (STEEL)= 30×106 psi Coefficient of linear expansion STEEL: 6.5 x 10-6 °/°F ALUM: 12 x 10-6/Farrow_forward01: A hollow steel tube (1) with an outside diameter of 2.75 in. and a wall thickness of 0.25 in, is fastened to a solid aluminum rod (2) that has a 2 in. diameter and a solid aluminum rod (3) that has a 1.375 in. diameter (E -30,000 ksi, E-10,000 ksil. The bar is loaded as shown in figure below, Determine: (1) the displacement of point D with respect to the fixed support at A. (2) the maximum normal stress in the entire axial assembly. (3) the normal strain in the steel tube (1). 34 kips 18 kips 25 kips 18 kips 34 kips 60 in. 40 in. 30 in.arrow_forward1) The cantilever bracket is bolted to a column with three M12 x 1.75 ISO 5.8 bolts. The bracket is made from AISI 1020 hot-rolled steel. Holes for M12 X 1.75 bolts 8 mm thick Find the factors of safety for the following failure modes: shear of 36 | 12 kN bolts, bearing of bolts, bearing of bracket, and bending of bracket. 32 64 Solution: 36 200 Colummarrow_forward

- Solve pleasearrow_forwardThe round cross-sectional bar is cut from an AISI 1020 colddrawn steel with a diameter of 25 mm. The bar is loaded at its end with a completely reversed load Fmin = 5 kN, Fmax = -3 kN. Using a design factor of nd = 1.2, what will be the maximum length of the bar that prevents failure using Modified Goodman criteria? What length must be used if a more conservative criteria is used?arrow_forwardAn AISI 1035 CD steel tube has an OD = 45 mm and a wall thickness of 5 mm. What maximum external pressure can this tube withstand if the largest principal normal stress is not to exceed 80 % of the minimum yield strength of the material? Assume ?? = 0.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY