Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

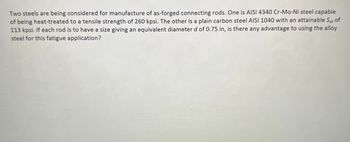

Transcribed Image Text:Two steels are being considered for manufacture of as-forged connecting rods. One is AISI 4340 Cr-Mo-Ni steel capable

of being heat-treated to a tensile strength of 260 kpsi. The other is a plain carbon steel AISI 1040 with an attainable Sut of

113 kpsi. If each rod is to have a size giving an equivalent diameter d of 0.75 in, is there any advantage to using the alloy

steel for this fatigue application?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 5 steps with 18 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A rectangular bar is cut from an AISI 1020 cold-drawn steel flat. The bar is 2.500 in wide by 4/8 in thick and has a 0.500-in-dia. hole drilled through the center as depicted in Table A-15-1. The bar is concentrically loaded in push-pull fatigue by axial forces Fa, uniformly distributed across the width. Using a design factor of na = 2, estimate the largest force Fa that can be applied ignoring column action. What is the largest force that can be applied to the part? (Round the final answer to three decimal places.) The largest force that can be applied is kips.arrow_forwardA rectangular bar is cut from an AISI 1020 cold-drawn steel flat. The bar is 2.500 in wide by 4/8 in thick and has a 0.500-in-dia. hole drilled through the center as depicted in Table A-15–1. The bar is concentrically loaded in push-pull fatigue by axial forces Fa, uniformly distributed across the width. Using a design factor of na = 2, estimate the largest force Fa that can be applied ignoring column action. What are the values of the theoretical stress-concentration factor, the notch sensitivity, and the fatigue stress-concentration factor? The value of the theoretical stress-concentration factor is The value of the notch sensitivity is (Round the final answer to three decimal places.) The value of the fatigue stress-concentration factor is (Round the final answer to three decimal places.)arrow_forwardA bar AISI 1035 steel forged and heat treated with minimum yield strength of 570MPa is subjected to bending moment of 290Nm and a torsional moment of 310Nm. Assuming a factor of safety of 2, determine the diameter of rod using the following theories of failure (i) Maximum Shear stress theory and (ii) Distortion Energy theory (iii) Maximum stress theory, also specify which diameter is considered as safearrow_forward

- A right angle bracket arm experiences a downward normal force F(t) which cycles continuously between a minimum of 100 Lbs to a maximum of 400 Lbs. The machined part is made from 4140 steel, quenched & tempered at 800°F (Table A-21). Determine the factor of safety of the 5/8- inch diameter shaft at point A based on a life >10 million cycles using the DE - ASME-Elliptic Fatigue Failure Theory. Consider 90 % reliability and room temperatures. Assume stress concentrations, Kf = Kt = 1.7 and Kfs = Kts = 1.4 at point A. List governing equations and show all work.arrow_forwardThe round cross-sectional bar is cut from an AISI 1020 colddrawn steel with a diameter of 25 mm. The bar is loaded at its end with a completely reversed load Fmin = 5 kN, Fmax = -3 kN. Using a design factor of nd = 1.2, what will be the maximum length of the bar that prevents failure using Modified Goodman criteria? What length must be used if a more conservative criteria is used?arrow_forwardI need help solving this problemarrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY