Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN: 9781305387102

Author: Kreith, Frank; Manglik, Raj M.

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Question

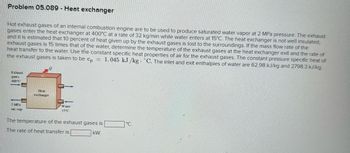

Transcribed Image Text:Problem 05.089 - Heat exchanger

Hot exhaust gases of an internal combustion engine are to be used to produce saturated water vapor at 2 MPa pressure. The exhaust

gases enter the heat exchanger at 400°C at a rate of 32 kg/min while water enters at 15°C. The heat exchanger is not well insulated,

and it is estimated that 10 percent of heat given up by the exhaust gases is lost to the surroundings. If the mass flow rate of the

exhaust gases is 15 times that of the water, determine the temperature of the exhaust gases at the heat exchanger exit and the rate of

heat transfer to the water. Use the constant specific heat properties of air for the exhaust gases. The constant pressure specific heat of

the exhaust gases is taken to be cp 1.045 kJ/kg "C. The inlet and exit enthalpies of water are 62.98 kJ/kg and 2798.3 kJ/kg.

=

Exhaust

gases

400°C

T

2 MPa

sat. vap.

Heat

exchanger

Water

15°C

The temperature of the exhaust gases is

The rate of heat transfer is

kW.

°C.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- A well-insulated heat exchanger is to heat water (cp = 4.18 kJ/kg-°C) from 25°C to 60°C at a rate of 0.5kg/s. %3D The heating is to be accomplished by geothermal water (cp = 4.31 kJ/kg-°C) available at 140°C at a mass flow rate of %3D 0.5 kg/s. What is the temperature of exit Brine. Water 25°C Brine 140°C 60°Carrow_forward6. A heat exchanger was installed purposely to cool 0.50 kg of gas per second. Molecular weight is 28 and k=1.32. The gas is cooled from 150 deg C to 80 deg C. Water is available at the rate of 0.30 kg/s and at a temperature of 12 deg C. Calculate the exit temperature of the water.arrow_forwardAmmonia and air pass through the heat exchanger. While the ammonia is entering as a superheated vapor at 16 bar pressure and 60C temperature it is leaving as a saturated liquid at the same pressure but unknown temperature. The ammonia mass flow rate is 400 kg/hour. Air is flowing backward and is heated from 17C to 42C at the constant pressure of 2 bars. NOTE: Find air properties from https://www.peacesoftware.de/einigewerte/luft_e.html a.Draw the sketch of the heat exchanger showing all thermodynamic parameters (P, T, etc.) Please show all steps of solutionarrow_forward

- Exhaust gases from a power plant are used to preheat air in a cross- flow heat exchanger. The exhaust gases enter the heat exchanger at 450°C and leave at 200°C. The air enters the heat exchanger at 70°C, leaves at 250°C, and has a mass flow rate of 10 kg/s. Assume the properties of the exhaust gases can be approximated by those of air. The overall heat transfer coefficient of the heat exchanger is 154 W/m²K. Calculate the heat exchanger surface area required if the air is unmixed and the exhaust gases are mixed .CPair = 1030 J/kg k Power plant Exhaust in, 450°C Exhaust gases Heat exchanger Air in, 70°C Air out, 250 ℃ Air intakes E Outarrow_forwardWater is used in a heat exchanger to cool 5 kg/s of air from 400 to 200 C. Calculate the minimum mass flow rate of the water if Twater =10 C.arrow_forwardA boiler has a mass flow rate of 3 tons/hour of feed water at a temperature of 28 C and a pressure of 1 atm. This water is pumped to a pressure of 30 atm assuming a constant temperature. Pump efficiency is 90%. The water leaving this pump is heated in an Economizer heat exchanger to its saturation point temperature in the saturated water phase? What is the rate of heat supplied by the Economizer to heat the pump exit feedwater to the above conditionsarrow_forward

- Question attachedarrow_forward. The exhaust gas regenerator (counter-flow heat exchanger) for a gas turbinehandles 1.9 kg/sec of air from its compressor and heats it by means of 2.2 kg/secof hot exhaust gas. Exhaust gas enters the regenerator at 596°C and leaves at312°C. Compressed air enters the regenerator at 220°C. For this temperaturerange a constant pressure specific heat for the exhaust has may be estimated at1090 J/kg-°C. Assume no heat transfer other than between the generator fluids.Determine the log mean temperature difference for the exchanger, °CA. 16.98 B. 26.98 C. 36.98 D. 46.98arrow_forwardProblem 4. Consider a steam turbine in which steam enters at 10.45 MPa and 780 K with a flow rate of 38.739 kg/s. A portion of the steam is extracted from the turbine after partial expansion at three different locations as shown in the sketch. The extracted steam is then led to various heat exchangers. The mass flow rates and the temperatures and pressures at each extraction point are given in the following table: Extraction Location m (kg/s) P (MPa) T (K) 4.343 3.054 620 Steam turbine Inlet 4.345 0.332 482 3 2.871 0.136 x = 0.949 The remaining wet steam exits the turbine at 11.5 kPa with a quality of 0.88. Estimate the power produced by the turbine assuming adiabatic operation and neg- ligible kinetic and potential energies for all streams. Exit 12 3 Extraction locatione 123arrow_forward

- Using that information and this table For the average monthly rate of geothermal heat available, determine, for the real case: in a tabular format and show sample calculation for one month. the necessary monthly average mass flow rate (in kg/s) of the refrigerant that must be pumped through the heat exchanger to collect the thermal energy from the available geothermal hot water flow rate if the hot water was cooled by 5°C. What should be the flow capacity (in kg/s) of feed pump of the ORC heat engine that you are designing and the monthly average net electric power generation capacity (in kW). 2. the monthly average net electric power generation capacity (in kW) and yearly average net electrical power generation capacity (in kW).arrow_forwardpart a b and carrow_forwardgive me solution math not explinarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi...Mechanical EngineeringISBN:9781305387102Author:Kreith, Frank; Manglik, Raj M.Publisher:Cengage Learning

Principles of Heat Transfer (Activate Learning wi...Mechanical EngineeringISBN:9781305387102Author:Kreith, Frank; Manglik, Raj M.Publisher:Cengage Learning

Principles of Heat Transfer (Activate Learning wi...

Mechanical Engineering

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Cengage Learning