Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

I need help solving problems 7, 8, and 9 pertaining to the print provided below.

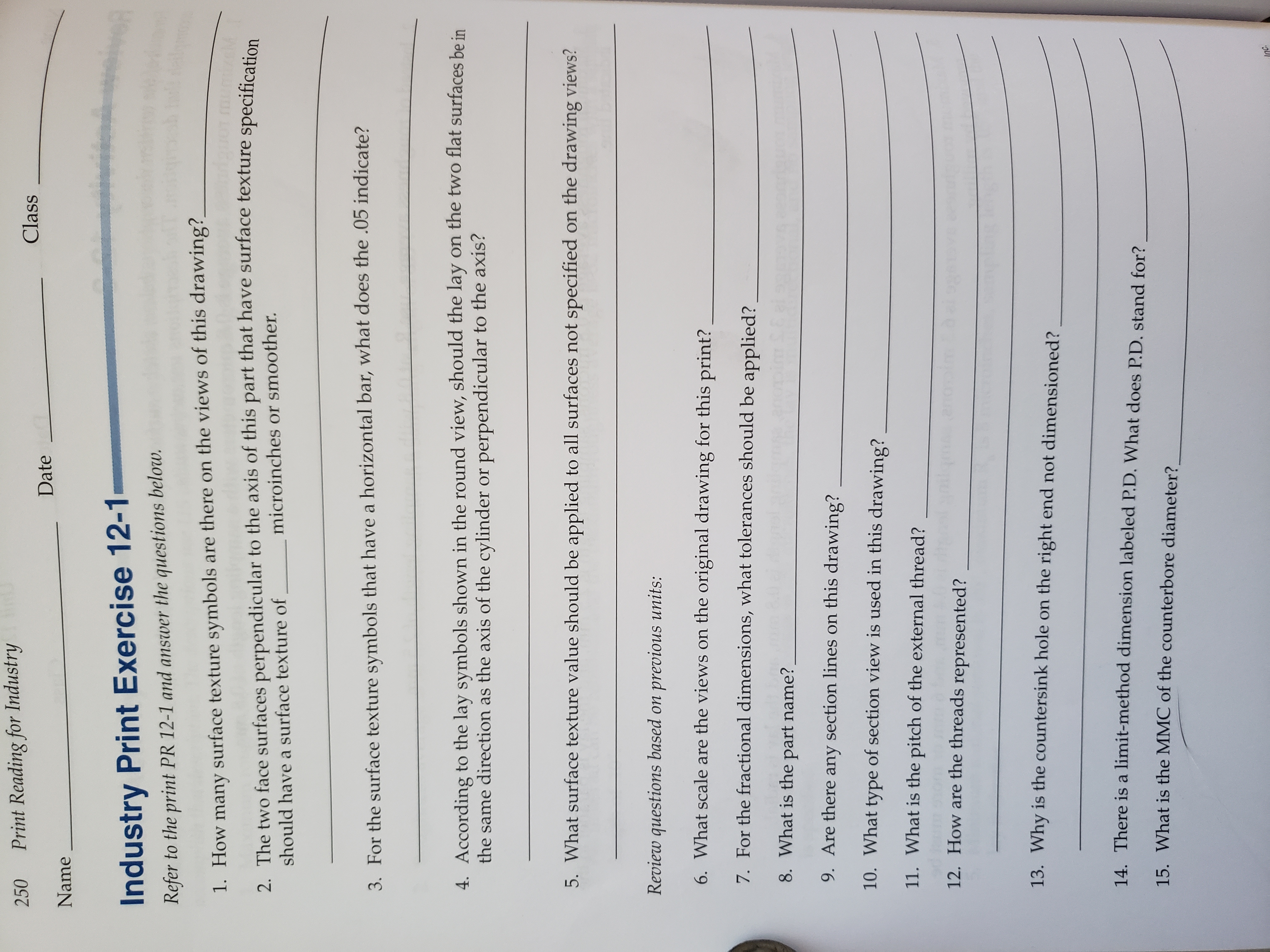

Transcribed Image Text:Print Reading for Industry

250

Class

Date

Name

Industry Print Exercise 12-1

Refer to the print PR 12-1 and answer the questions below.

1. How many surface texture symbols are there on the views of this drawing?

2. The two face surfaces perpendicular to the axis of this part that have surface texture specification

microinches or smoother.

should have a surface texture of

3. For the surface texture symbols that have a horizontal bar, what does the .05 indicate?

on the two flat surfaces be in

4. According to the lay symbols shown in the round view, should the lay

the same direction as the axis of the cylinder or perpendicular to the axis?

5. What surface texture value should be applied to all surfaces not specified on the drawing views?

Review questions based on previous units:

6. What scale are the views on the original drawing for this print?

7. For the fractional dimensions, what tolerances should be applied?

8. What is the part name?

9. Are there any section lines on this drawing?

10. What type of section view is used in this drawing?

11. What is the pitch of the external thread?

12. How are the threads represented?

13. Why is the countersink hole on the right end not dimensioned?

14. There is a limit-method dimension labeled P.D. What does P.D. stand for?

15. What is the MMC of the counterbore diameter?

Inc.

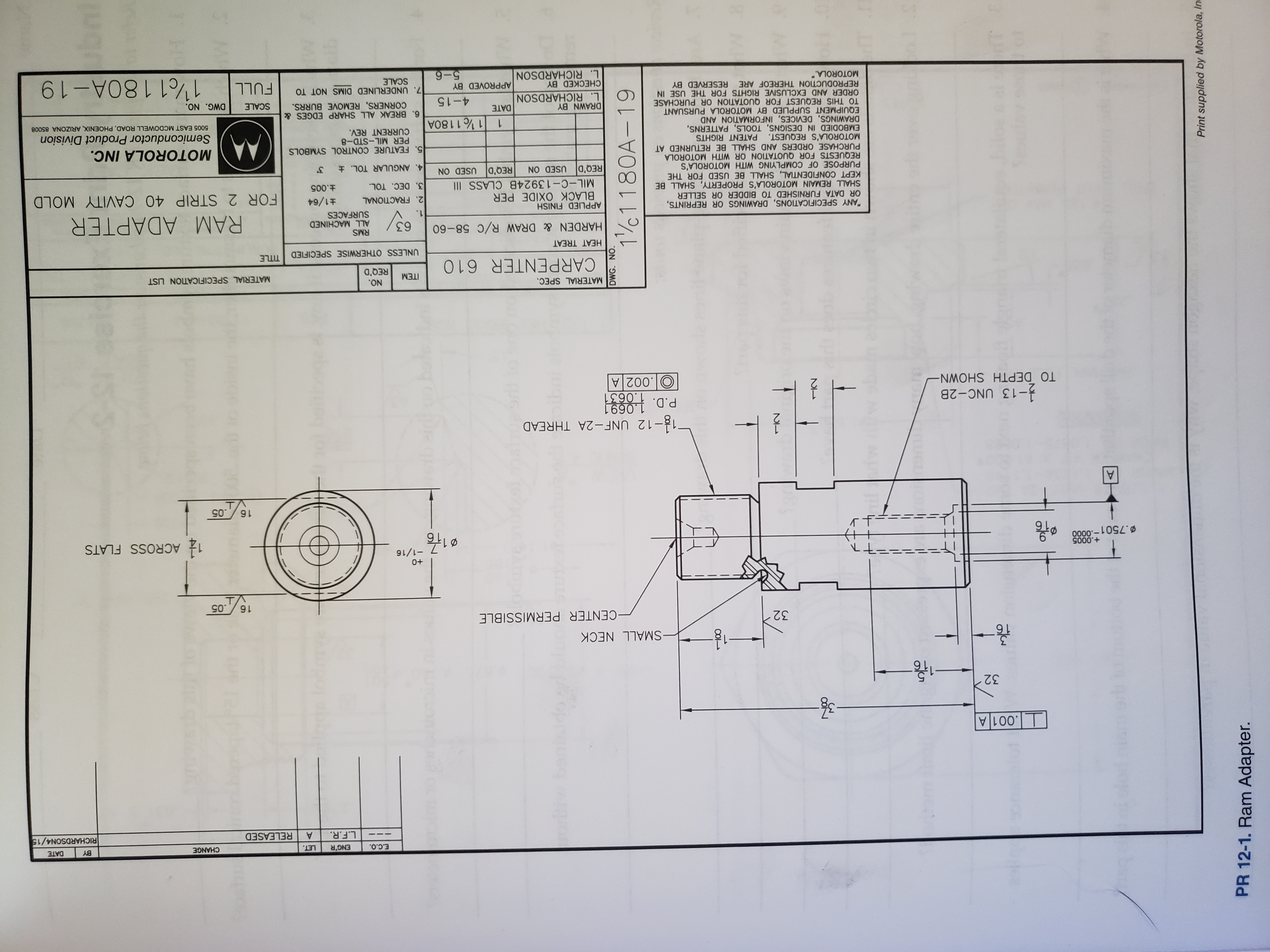

Transcribed Image Text:DWG. NO.

11180A-19

1100

12

oe & al ectT

Print supplied by Motorola, In

PR 12-1. Ram Adapter.

E.C.O.

ENG'R

LET.

CHANGE

BY

DATE

L.F.R.

RELEASED

RICHARDSON4/15

.001 A

32

3

16

-SMALL NECK

32

-CENTER PERMISSIBLE

.05

T

0+

-1/16

+.0005

D.7501-0000

1:

116

ACROSS FLATS

+

왕이

16.05

A

12-12 UNF-2A THREAD

P.D. 1.0691

1.0631

-13 UNC-2B

TO DEPTH SHOWN -

O.002 A

MATERIAL SPEC.

NO.

ITEM

MATERIAL SPECIFICATION LIST

REQ'D

CARPENTER 610

UNLESS OTHERWISE SPECIFIED TITLE

HEAT TREAT

RMS

ALL MACHINED

SURFACES

HARDEN& DRAW R/C 58-60

63

RAM ADAPTER

1.

"ANY SPECIFICATIONS, DRAWINGS OR REPRINTS,

OR DATA FURNISHED TO BIDDER OR SELLER

SHALL REMAIN MOTOROLA'S PROPERTY, SHALL BE

KEPT CONFIDENTIAL, SHALL BE USED FOR THE

PURPOSE OF COMPLYING WITH MOTOROLA'S

REQUESTS FOR QUOTATION OR WITH MOTOROLA

PURCHASE ORDERS AND SHALL BE RETURNED AT

MOTOROLA'S REQUEST. PATENT RIGHTS

EMBODIED IN DESIGNS, TOOLS, PATTERNS,

DRAWINGS, DEVICES, INFORMATION AND

EQUIPMENT SUPPLIED BY MOTOROLA PURSUANT

TO THIS REQUEST FOR QUOTATION OR PURCHASE

ORDER AND EXCLUSIVE RIGHTS FOR THE USE IN

REPRODUCTION THEREOF ARE RESERVED BY

MOTOROLA."

APPLIED FINISH

BLACK OXIDE PER

2. FRACTIONAL

3. DEC. TOL

1/64

FOR 2 STRIP 40 CAVITY MOLD

MIL-C-13924B CLASS II

t.005

REQ'D USED ON

REQ'D USED ON

4. ANGULAR TOL. t

MOTOROLA INC.

5. FEATURE CONTROL SYMBOLS

PER MIL-STD-8

CURRENT REV.

Semiconductor Product Division

1 / 1 180A

5005 EAST MCDOWELL ROAD, PHOENIX, ARIZONA 85008

DRAWN BY

L. RICHARDSON

6. BREAK ALL SHARP EDGES &

CORNERS, REMOVE BURRS.

DATE

4-15

SCALE

DWG. NO.

7. UNDERLINED DIMS NOT TO

SCALE

1/01 180A-19

CHECKED BY

APPROVED BY

FULL

L. RICHARDSON

9-9

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Thank you for your response. Please continue to provide the solution to the remainder of Part 1 (d and e).arrow_forwardHandwriting not allow please And give me complete answerarrow_forwardI asked for problems 6 and 7 to be answered, but I did not get a properly structured answered as the example shows on problem number 1. Here is the link to the questions I already had answered, could you please rewrite the answer so its properly answered as the example shows (Problem 1)? https://www.bartleby.com/questions-and-answers/it-vivch-print-reading-for-industry-228-class-date-name-review-activity-112-for-each-local-note-or-c/cadc3f7b-2c2f-4471-842b-5a84bf505857arrow_forward

- I want to explain how to count j1 (half joints) and j2 (full joints) in the degree of freedom and when i increase a number or decrease a number when counting like this drawing. I want all the rules related to counting the point with an explanation (mechanical system) plssarrow_forwardQuestion 4 a) Each cylinder in a four-cylinder car engine has a bore diameter of 63.53 mm and the stroke for each piston is 175.00 mm. Calculate the cubic capacity of the engine in cm? and calculate the clearance volume per cylinder for a compression ratio, r, of 6.25. b) The bore diameter of each cylinder in a six-cylinder four-stroke internal combustion engine is 32 mm and the stroke of each piston is 125 mm. During testing., the engine runs at 1450 revolutions per minute (rpm) with a pressure-volume indicator diagram showing a mean net area of 2.90 cm and a diagram length of 0.85 cm. The pressure scale on the indicator diagram is set to 165 kN/m per cm. Calculate the mean effective pressure (m.e.p) and the indicated power in kilowatts (kW) developed by this six-cylinder four-stroke engine. Give your answer to 2 decimal c) A hollow connecting rod has an inner diameter of 26.25 mm and is subjected to an axial tensile load of 500 MN. If the maximum allowable stress for this hollow rod…arrow_forward3darrow_forward

- Please answer in the column by using the answer provided.arrow_forwardI was given this image for the purpose of studying for an upcoming exam. No additional info was given. Any suggestions on how to study for potential questions that could be asked about this image?arrow_forwardAt operating stress of 420MPa, the number of cycles to fail a specimen is 65 cycles. At operating stress of 360MPa, the number of cycles to fail the specimen is 390 cycles, and at operating stress of 130MPa, the number of cycles to fail the specimen is 11,900 cycles. A test sequence as follows is designed: first, operating stress of 420MPa for 7 cycles, second, operating stress of 360MPa for 65 cycles, and third, operating stress of 130MPa for 325 cycles. Determine at what number of cycle and which operating stress level the specimen would be expected to fail if the above sequence is repeated.arrow_forward

- Part 2 Set up a spreadsheet solution to this problem. This will require that you derive one formula to express the relationship between the friction coefficient, the spring constant, and the spring compression; and a second formula to find the cost of using different slide and spring types. Set up your spreadsheet as shown below. You can fill in the "Acceptable?" column manually, rather than using a formula. Turn in a copy of your spreadsheet/Matlab work (solve for $) Friction Spring Constant Spring Compression M k 0.1 0.1 0.1 0.2 0.2 0.2 50 100 150 50 100 150 4 Part 3 Your boss has decided to look at a second option. The spring mechanism will be replaced by a drop box. After leaving the slide, the blocks will travel 5 horizontal feet through the air and pass through a hole into the drop box. Using the slide you selected above, determine how far below the slide (h) to place the hole in the drop box. Yo = 5.2017/5 BLADE 2 RAMPE SLIDE 8⁰ SLIDE Acceptable? (Yes or No) $' Cost 51 In DROP…arrow_forwardHelp me Part E!!! Answer it correctly!!! Make sure you solve work on hand!!! Answer correctly Please!!!!!!!arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY