Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

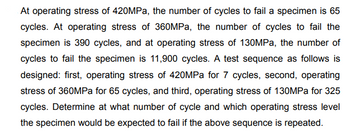

Transcribed Image Text:At operating stress of 420MPa, the number of cycles to fail a specimen is 65

cycles. At operating stress of 360MPa, the number of cycles to fail the

specimen is 390 cycles, and at operating stress of 130MPa, the number of

cycles to fail the specimen is 11,900 cycles. A test sequence as follows is

designed: first, operating stress of 420MPa for 7 cycles, second, operating

stress of 360MPa for 65 cycles, and third, operating stress of 130MPa for 325

cycles. Determine at what number of cycle and which operating stress level

the specimen would be expected to fail if the above sequence is repeated.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 4 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- The following curve is a result of a tensile test. The gauge length was 2 in, and the specimen diameter was 0.505 in The fracture area was round with a diameter of 0.391 in. Remember to com 20000 Force (pounds force) 15000 10000 5000 0 16. The yield strength is 0 0.2% O 80,000 pl O 12.000 p 060,000 pl 85,000 p 0.1 0.2 Extension (inch) 0.3 0.4arrow_forwardThe results of a tensile test are: Diameter of the specimen Gauge length Load at limit of Proportionality Extension at the limit of Proportionality Maximum Load : 10mm :40 mm : 70kN :0.08mm. :100 kN Calculate stress at limit of proportionality and young's modulus.arrow_forwardQUESTION The following data were obtained during a tension test of a low carbon steel specimen having a gauge length of 100 mm. At the point where the stress strain curve deviated from linearity, the load was 35KN, the gauge length was 102.5 mm and the diameter of the specimen was 1.6 mm. Before necking began, loads of 45 KN and 55 KN produced gauge lengths of 103.4 mm and 107.7 mm respectively. Calculate (a) The Modulus of elasticity (b) The Strainhardening exponentarrow_forward

- (d) Following experimental data (TableQ1b) has obtained from the torsion test for the specimen dimension given in Table Q1a. Determine the material of a circular bar. (Take the material Poisson's Ratio as 0.32) Table Q1a Specimen Dimensions Dimensions Material Diameter (mm) 6 Length (mm) 77.15 TableQ1b Experimental Results from Torsion test Angular Deflection Degree Radian Torque/Nm 0.5 0.008727 0.06 1 0.017453 0.47 1.5 0.02618 0.76 2 0.034907 1.01 2.5 0.043633 1.32 3 0.05236 1.65 3.5 0.061087 1.99 4 0.069813 2.32 4.5 0.07854 2.66 5 0.087267 3.00 5.5 0.095993 3.33 6 0.10472 3.64 10 0.174533 5.92 20 0.349066 7.74 30 0.523599 8.07 40 0.698132 8.17 50 0.872665 7.93 60 1.047198 8.10 70 1.221731 8.2 80 1.396264 8.4 90 1.570797 8.24 100 1.74533 8.7 110 1.919863 8.7 120 2.094396 8.7 180 3.141594 9.02 240 4.188792 9.11 300 5.23599 9.48 360 6.283188 9.51 420 7.330386 9.71arrow_forward1. A tensile test was conducted on a metal "505" specimen and the following stress-strain curves were generated, both curves generated from the same set of data. Use the graphs to fill in the mechanical properties of the material tested in the box below. Don't forget units! Stress vs Strain Stress, psi Stress, psi 80000 70000 60000 50000 40000 30000 20000 10000 0 0.00 80000 70000 60000 50000 40000 30000 20000 10000 0.02 0 0.000 0.002 0.04 0.004 0.06 0.006 0.08 0.10 Strain Stress vs Strain 0.008 0.12 Elastic Modulus, E: 0.2% Offset Yield Strength, oo: Tensile Strength, ou: Breaking Strength, of: % Elongation: 0.14 0.010 0.012 0.014 Strain 0.16 0.18 0.016 0.018 0.20 0.020arrow_forwardplease wright by handarrow_forward

- The answer is one of the options below please solve carefully and circle the correct option Please write clear .arrow_forwardQ19 and Q20arrow_forwardA tensile test was performed on a metal specimen with a diameter of 1/2 inch and a gage length (the length over which the elongation is meas- ured) of 4 inches. The data were plotted on a load-displacement graph, P vs. AL. A best-fit line was drawn through the points, and the slope of the straight-line portion was calculated to be P/AL = 1392 kips/in. What is the modulus of elasticity? BIarrow_forward

- I need the answer as soon as possiblearrow_forwardQ1/ The table below shows the values of stress amplitude and life cycles : Fatigue strength Sf (Mpa) Number of cycles (Nf) 474 111 417 496 352 3002 316 7065 290 21930 262 66075 The test were done, to estimate the failure, on un-notched axially load specimens under zero mean stress. Calculate a and b using the stress -life equation.arrow_forward2. The Goodman diagram relates oa and Om for fatigue failure after a specific number of cycles Nf, where da is the cyclic stress amplitude, and om the mean stress. For a steel specimen it is found that oa = a (0).[1- (om/OTS)] where OTS is the metal's tensile stress (375MPa), and a (0)~0.450TS is the 10' cycle fatigue limit at zero mean stress. Assuming the specimen is cycled repeatedly between 0 stress and a peak stress, what is the maximum peak stress if failure in < 107 cycles is to be avoided?arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY