Principles of Accounting Volume 2

19th Edition

ISBN: 9781947172609

Author: OpenStax

Publisher: OpenStax College

expand_more

expand_more

format_list_bulleted

Question

carefully check details and give nas

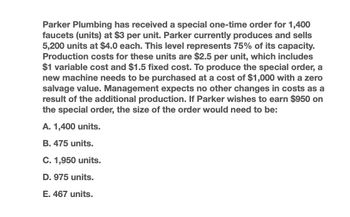

Transcribed Image Text:Parker Plumbing has received a special one-time order for 1,400

faucets (units) at $3 per unit. Parker currently produces and sells

5,200 units at $4.0 each. This level represents 75% of its capacity.

Production costs for these units are $2.5 per unit, which includes

$1 variable cost and $1.5 fixed cost. To produce the special order, a

new machine needs to be purchased at a cost of $1,000 with a zero

salvage value. Management expects no other changes in costs as a

result of the additional production. If Parker wishes to earn $950 on

the special order, the size of the order would need to be:

A. 1,400 units.

B. 475 units.

C. 1,950 units.

D. 975 units.

E. 467 units.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- Vollmer Manufacturing makes three components for sale to refrigeration companies. The components are processed on two machines: a shaper and a grinder. The times (in minutes) required on each machine are as follows: The shaper is available for 120 hours, and the grinder for 110 hours. No more than 200 units of component 3 can be sold, but up to 1,000 units of each of the other components can be sold. In fact, the company already has orders for 600 units of component 1 that must be satisfied. The profit contributions for components 1, 2, and 3 are 8, 6, and 9, respectively. a. Formulate and solve for the recommended production quantities. b. What are the objective coefficient ranges for the three components? Interpret these ranges for company management. c. What are the right-hand-side ranges? Interpret these ranges for company management. d. If more time could be made available on the grinder, how much would it be worth? e. If more units of component 3 can be sold by reducing the sales price by 4, should the company reduce the price?arrow_forwardDimitri Designs has capacity to produce 30,000 desk chairs per year and is currently selling all 30,000 for $240 each. Country Enterprises has approached Dimitri to buy 800 chairs for $210 each. Dimitris normal variable cost is $165 per chair, including $50 per unit in direct labor per chair. Dimitri can produce the special order on an overtime shift, which means that direct labor would be paid overtime at 150% of the normal pay rate. The annual fixed costs will be unaffected by the special order and the contract will not disrupt any of Dimitris other operations. What will be the impact on profits of accepting the order?arrow_forwardRemarkable Enterprises requires four units of part A for every unit of Al that it produces. Currently, part A is made by Remarkable, with these per-unit costs in a month when 4,000 units were produced: Variable manufacturing overhead is applied at $1.60 per unit. The other $0.50 of overhead consists of allocated fixed costs. Remarkable will need 8,000 units of part A for the next years production. Altoona Corporation has offered to supply 8,000 units of part A at a price of $8.00 per unit. If Remarkable accepts the offer, all of the variable costs and $2,000 of the fixed costs will be avoided. Should Remarkable accept the offer from Altoona Corporation?arrow_forward

- Power Corp. makes 2 products: blades for table saws and blades for handsaws. Each product passes through the sharpening machine area, which is the chief constraint during production. Handsaw blades take 15 minutes on the sharpening machine and have a contribution margin per blade of $15. Table saw blades take 20 minutes on the sharpening machine and have a contribution margin per blade of $35. If it is assumed that Power Corp. has 5,000 hours available on the sharpening machine to service a minimum demand for each product of 4,000 units, how much will profits increase if 200 more hours of machine time can be obtained?arrow_forwardPower Corp. makes 2 products: blades for table saws and blades for handsaws. Each product passes through the sharpening machine area, which is the chief constraint during production. Handsaw blades take 15 minutes on the sharpening machine and have a contribution margin per blade of $15. Table saw blades take 20 minutes on the sharpening machine and have a contribution margin per blade of $35. If it is assumed that Power Corp. has 5,000 hours available on the sharpening machine to service a minimum demand for each product of 4,000 units, how many of each product should be made?arrow_forwardBox Springs, Inc., makes two sizes of box springs: twin and double. The direct material for the twin is $25 per unit and $40 s used in direct labor, while the direct material for the double is $40 per unit, and the labor cost is $50 per unit. Box Springs estimates it will make 5,000 twins and 9,000 doubles in the next year. It estimates the overhead for each cost pool and cost driver activities as follows: How much does each unit cost to manufacture?arrow_forward

- Cinnamon Depot bakes and sells cinnamon rolls for $1.75 each. The cost of producing 500,000 rolls in the prior year was: At the start of the current year, Cinnamon Depot received a special order for 18,000 rolls to be sold for $1.50 per roll. The company estimates it will incur an additional $1,000 in total fixed costs in order to lease a special machine that forms the rolls in the shape of a heart per the customers request. This order will not affect any of its other operations. Should the company accept the special order? (Show your work.)arrow_forwardPhillips HVAC and Plumbing has received a special one-time order for 1,500 faucets (units) at $5 per unit. Phillips currently produces and sells 7,500 units at $6.00 each. This level represents 75% of its capacity. Production costs for these units are $4.50 per unit, which includes $3.00 variable cost and $1.50 fixed cost. To produce the special order, a new machine needs to be purchased at a cost of $1,000 with a zero salvage value. Phillips management expects no other changes in costs as a result of the additional production. Should the Phillips accept the special order? 1)No, because additional production would exceed capacity. 2)Yes, because incremental costs exceed incremental revenues. 3)Yes, because incremental revenue exceeds incremental costs. 4)No, because incremental costs exceed incremental revenue. 5)No, because the incremental revenue is too low.arrow_forwardMinor Electric has received a special one-time order for 1,500 light fixtures (units) at $5 per unit. Minor currently produces and sells 7,500 units at $6.00 each. This level represents 75% of its capacity. Production costs for these units are $4.50 per unit, which includes $3.00 variable cost and $1.50 fixed cost. To produce the special order, a new machine needs to be purchased at a cost of $1,000 with a zero salvage value. Management expects no other changes in costs as a result of the additional production. If Minor wishes to earn $1,250 on the special order, the size of the order would need to be:arrow_forward

- Theta company has received a special one-time order for 1,500 light fixtures (units) at P15 per unit. It currently produces and sells 7,500 units at 16.00 each. This level represents 75% of its capacity. Production costs for these units are P19.50 per unit, which includes 13.00 variable cost and 6.50 fixed cost. To produce the special order, a new machine needs to be purchased at a cost of P725 with a zero salvage value. Management expects no other changes in costs as a result of the additional production. If the company wishes to earn 1,375 on the special order, the size of the order would need to be: 1) 2,100 units. 2) 4,200 units. 3) 100 units. 4) 1,050 units. 5) 935 units.arrow_forwardProvide answer for the following Questionarrow_forwardThe Mighty Music Company produces and sells a desktop speaker for $200. The company has the capacity to produce 60,000 speakers each period. At capacity, the costs assigned to each unit are as follows: Unit-level costs Product-level costs Facility-level costs The company has received a special order for 11,000 speakers. If this order is accepted, the company will have to spend $20,000 on additional costs. Assuming that no sales to regular customers will be lost if the order is accepted, at what selling price will the company be indifferent between accepting and rejecting the special order? Multiple Choice O O $96.82 $146.82 $104.32 $95 $25 $15 $107.32arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

- Principles of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College

Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning

Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning Principles of Cost AccountingAccountingISBN:9781305087408Author:Edward J. Vanderbeck, Maria R. MitchellPublisher:Cengage Learning

Principles of Cost AccountingAccountingISBN:9781305087408Author:Edward J. Vanderbeck, Maria R. MitchellPublisher:Cengage Learning

Principles of Accounting Volume 2

Accounting

ISBN:9781947172609

Author:OpenStax

Publisher:OpenStax College

Essentials of Business Analytics (MindTap Course ...

Statistics

ISBN:9781305627734

Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. Anderson

Publisher:Cengage Learning

Principles of Cost Accounting

Accounting

ISBN:9781305087408

Author:Edward J. Vanderbeck, Maria R. Mitchell

Publisher:Cengage Learning