Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Topic Video

Question

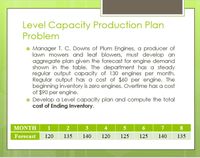

Transcribed Image Text:Level Capacity Production Plan

Problem

o Manager T. C. Downs of Plum Engines, a producer of

lawn mowers and leaf blowers, must develop an

aggregate plan given the forecast for engine demand

shown in the table. The department has a steady

regular output capacity of 130 engines per month.

Regular output has a cost of $60 per engine. The

beginning inventory is zero engines. Overtime has a cost

of $90 per engine.

o Develop a Level capacity plan and compute the total

cost of Ending Inventory.

MONTH

1

2

3

4

6

7

8.

Forecast

120

135

140

120

125

125

140

135

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- degree nozzle sprinklers, 180-degree nozzle sprinklers, and 360-degree nozzle sprinklers. Management has forecast demand for the next four years as follows: Plastic 90 Plastic 180 Plastic 360 Bronze 90 Bronze 180 Bronze 360 1 (IN 000s) 33 15 46 4 5 7 Plastic Demand for plastic sprinklers Percentage of capacity used Machine requirements Labor requirements Bronze YEARLY DEMAND 2 (IN 000s) 45 16 55 9 5 11 Both production lines can produce all the different types of nozzles. The bronze machines needed for the bronze sprinklers require three operators and can produce up to 11,000 sprinklers. The plastic injection molding machine needed for the plastic sprinklers requires three operators and can produce up to 180,000 sprinklers. Three bronze machines and only one injection molding machine are available. Demand for bronze sprinklers Percentage of capacity used Machine requirements Labor requirements What are the capacity requirements for the next four years? (Assume that there is no…arrow_forwardLMNO Gaskets has formulated a production plan for a product to meet demand over the upcoming four quarters. Demand in each of the four quarters and production, overtime, and subcontracting capacities are reported in the table below, in addition to the feasible production plan. The relevant costs are: • Regular time production cost is $10/unit. Overtime production cost is $14/unit. Subcontracting cost is $18/unit Inventory is held at a cost of $1/unit/quarter. • Units may be backordered at a cost of $4/unit/quarter. Production Resource Regular Time Q1 Overtime Q1 Subcontract Q1 Regular Time Q2 Overtime Q2 Subcontract Q2 Regular Time Q3 Overtime Q3 Subcontract Q3 Demand in Quarter Demand in Quarter Q2 0 20 0 550 Q1 550 230 0 0 0 0 40 40 0 860 250 470 0 40 0 1330 What is the inventory cost for the year? What is the backorder cost for the year? What is the total cost for the year? Q3 0 0 0 0 0 30 510 160 0 700 What is the total overtime production cost for the year? Capacity 550 250 500…arrow_forwardIt wouldnt let me take a screenshot of the table so I had to copy and paste it in here. My question is: How do you Calculate a moving average forecast using the last 2 and 4 dates of stay. What is the prediction for 7/1/2021 for each technique? Discussion Question 1 - 200 room hotel Forecasts MA 2 Errors MA 4 Errors ES (0.8) Errors ES (0.5) Errors Date Day of Week Rooms Sold MA 2 MA 4 ES (0.8) ES (0.5) AE APE AE APE AE APE AE APE 6/1/2021 Tuesday 123 6/2/2021 Wednesday 109 6/3/2021 Thursday 140 6/4/2021 Friday 199 6/5/2021 Saturday 179 6/6/2021 Sunday 140 6/7/2021 Monday 117 6/8/2021 Tuesday 132 6/9/2021 Wednesday 108 6/10/2021 Thursday 151…arrow_forward

- b) What are the components of service package! S. Prepare an aggregate plan for the following information of demand forecast as given in the table below. Period 1 Demand (units) 55 2 49 Regular Production Cost Overtime production Cost Regular Production capacity 3 60 4 57 5 45 : Rs 60 per unit : Rs 80 per unit : 50 units per period : Rs 5 per unit per period Inventory cost Overtime Production capacity: 10 Units per period : Rs 150 per unit : Unlimited : Nil 6 60 7 8 50 65 9 55 Subcontracting cost Subcontracting capacity Beginning Inventory Use regular production and supplement using inventory, overtime and subcontracting.arrow_forwardWhat is CAPACITY REQUIREMENTS FORECASTING?arrow_forwardThe S&OP team at Kansas Furniture, led by David Angelow, has received estimates of demand requirements as shown in the table. Assuming one-time stockout costs for lost sales of $125 per unit, Kinventory carrying costs of $25 per unit per month, and zero beginning and ending inventory, evaluate the following plan on an incremental cost basis: Plan B: Vary the workforce to produce the prior month's demand. Demand was 1,300 units in June. The cost of hiring additional workers is $30 per unit produced. The cost of layoffs is $65 per unit cut back. (Enter all responses as whole numbers.) Note: Both hiring and layoff costs are incurred in the month of the change (i.e., going from production of 1,300 in July to 1200 in August requires a layoff (and related costs) of 100 units in August). Stockouts (Units) Month 1 July Demand 1200 Hire Production (Units) Layoff Ending (Units) Inventory 2 August 1300 3 September 1200 4 October 1700 5 November 1650 6 December 1650arrow_forward

- Solve all this question compulsory........arrow_forward1. What factors should be considered when selecting the appropriate capacity cushion? Howdoes the choice of capacity cushion relate to other decisions in operations management?To other functional areas? 2. Capacity planning requires a demand forecast for an extended period of time into thefuture. What concerns would you have regarding an extended forecast as a capacityplanner?arrow_forwardJAYB, manager of a Fabrication company, has the following aggregate demand requirements and other data for the upcoming four quarters. Table 5: Forecast and cost information [Jadual 5: Maklumat Ramalan dan kos] Quarter [Suku] Demand [Permintaan] Previous quarter's output [Keluaran suku sebelumnya] 1,500 units 1 1,400 Beginning inventory [Inventori awal] 200 units 2 1,000 Hiring workers [Pengambilan pekerja] RM6 per unit 3 1,500 Laying off workers [Pembuangan pekerja] RM11 per unit 4 1,300 Unit cost [Kos unit] RM30 per unit With the information given, JAYB wants you to calculate the total cost of using chase strategy by hiring and layoff workers.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.