Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

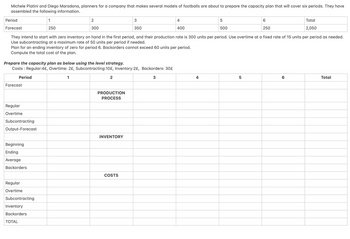

Transcribed Image Text:Michele Platini and Diego Maradona, planners for a company that makes several models of footballs are about to prepare the capacity plan that will cover six periods. They have

assembled the following information.

1

250

2

300

4

400

They intend to start with zero inventory on hand in the first period, and their production rate is 300 units per period. Use overtime at a fixed rate of 15 units per period as needed.

Use subcontracting at a maximum rate of 50 units per period if needed.

Plan for an ending inventory of zero for period 6. Backorders cannot exceed 60 units per period.

Compute the total cost of the plan.

Period

Forecast

Prepare the capacity plan as below using the level strategy.

Costs: Regular:4£, Overtime: 2£, Subcontracting:10£, Inventory:2£, Backorders: 30£

1

3

Period

Forecast

Regular

Overtime

Subcontracting

Output-Forecast

Beginning

Ending

Average

Backorders

Regular

Overtime

Subcontracting

Inventory

Backorders

TOTAL

2

PRODUCTION

PROCESS

INVENTORY

3

350

COSTS

4

5

500

LO

5

6

250

(O

Total

2,050

Total

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 2 images

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

can you explain what that implies? for example if you were to write a short note on your results

Solution

by Bartleby Expert

Follow-up Question

Prepare the capacity plan using the chase strategy, and compute the costs.

Solution

by Bartleby Expert

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

can you explain what that implies? for example if you were to write a short note on your results

Solution

by Bartleby Expert

Follow-up Question

Prepare the capacity plan using the chase strategy, and compute the costs.

Solution

by Bartleby Expert

Knowledge Booster

Similar questions

- Capacity Requirements Planning Abe is typically scheduled to operate 4 machines at his workstation for 8 hours per day, 5 days per week. During every 8 hours of scheduled work, Abe takes 45 minutes of break. He must perform 20 minutes of maintenance on each machine (separately) during every 8 hours of scheduled work. Abe is unable to process work while he is performing maintenance. Abe’s company is making some changes to the maintenance schedule. The changes will result in a new weekly capacity of 6000 minutes when Abe is scheduled for a 40-hour work week. The following jobs are to be done at the workstation next week (times are in minutes): Job # Units Setup Time Run Time/Unit A 840 25 3 B 152 50 6 C 525 60 4 D) Given the new weekly capacity of 6000 minutes, what is the load% for next week?arrow_forwardWhich approach to process planning is more useful in a time-sharing environment?arrow_forwardMaple Leaf Founda ry, owned by Ahmet Satir, producescast-iron ingots according to a 3-month capacity plan. Thecost of labor averages $100 per regular shift hour and $140 perovertime (O.T.) hour. Inventory carrying cost is thought to be$4 per labor-hour of inventory carried. There a re 50 direct laborhours of inventory left over from March. For the next 3 months,demand and capacity (in labor-hours) are as follows: Develop an aggregate p lan for the 3-month period using thetransportation method.arrow_forward

- A barbershop has been using a level workforce of barbers five days per week, Tuesday through Saturday. The barbers have considerable idle time on Tuesday through Friday, with certain peak periods during the lunch hours and after 4 p.m. each day. On Friday afternoon and all day Saturday, all the barbers are very busy, with customers waiting a substantial amount of time and some customers being turned away. What options should this barbershop consider for aggregate planning? Howwould you analyze these options? What data should be collected, and how should the options be compared?arrow_forwardProblem #1: Extension of the solved problem in the class The washing machine plant is interested in determining work force and production levels for the next 8 months. Forecasted demands for Jan-Aug, are: 420, 280, 460, 190, 310, 145, 110, 125. Starting inventory at the end of December is 200. The firm would like to have 100 units on hand at the end of August. Suppose we are told that over a period of 40 days, the plant had 38 workers who produced 520 units. Assume we are given the following number of working days per month (January to August): 22, 16, 23, 20, 21, 22, 21, 22. The holding cost (per unit per month): $8.50, hiring cost per worker: $800, firing cost per worker: $1,250, payroll cost: $75/worker/day, and shortage cost: $50 unit short/month. The company has 40 workers at the end of December. We solved this problem in class and obtained a value of K = 0.3421 units/worker/day. In addition, we developed a constant workforce plan with 46 workers over the planning horizon and…arrow_forwardPlease dont give answer in image format . Do type the answer !arrow_forward

- Up, Up, and Away is a producer of kites and wind socks. Relevant data on the bottleneck operation in the shop for the upcoming fiscal year are given in the following table: (i Item Demand forecast Lot size Standard processing time Standard setup time Kites 30,000 units/year 15 units 0.4 hour/unit 3.0 hours/lot Wind Socks 15,000 units/year 80 units 1.0 hour/unit 4.0 hours/lot The shop works two shifts per day, 8 hours per shift, 220 days per year. Currently, the company operates four machines, and desires a 25 percent capacity cushion. How many machines should be purchased to meet the upcoming year's demand without resorting to any short-term capacity solutions? The number of additional machines required is. (Enter your response rounded up to the next whole number.)arrow_forwardTailwind, Inc., produces high-quality but expensive training shoes for runners. The Tailwind shoe, which sells for $210, contains both gas- and liquid-filled compartments to provide more stability and better protection against knee, foot, and back injuries. Manufacturing the shoes requires 10 separate tasks. There are 400 minutes available for manufacturing the shoes in the plant each day. Daily demand is 60. The information for the tasks is as follows: Performance Time Task Must Follow This Task ABCDEFGHI · Task (in minutes) А В Е Н 1 -324-325- - A B B C, D A F G E, H J 3 | Total 25 Required: a. Draw the precedence diagram showing the task precedence and their times b. Determine the cycle time associated with the rate of output required. c. What is the theoretical minimum number of work stations required to satisfy this output rate? d. Allocate the tasks to work stations taking into consideration the precedence requirements and using the LOT rule to break ties between feasible tasks.…arrow_forwardThe table gives the total cost schedule for oil changes at the local Jiffy Lube. What is Jiffy Lube's total fixed cost?arrow_forward

- Processing Capacity in Operational Analysis. Please calculate where is the Bottleneck. Please show how to calculate in an Excel spreadsheet.arrow_forwardExplain Sales and Operations Planning with example?arrow_forwardThe Morning Brew Coffee Shop sells Regular, Cappuccino, and Vienna blends of coffee. The shop's current daily labor cost is $320, the equipment cost is $125, and the overhead cost is $225. Daily demands, along with price and material costs per beverage, are given below: Regular Vienna Cappuccino Coffee coffee Beverages sold 400 100 200 Price per beverage $2.00 Material per beverage ($) $0.50 $3.00 $0.75 $4.00 $1.25 Harald Luckerbauer, the manager at Morning Brew Coffee Shop, would like to understand how adding Eiskaffee (a German coffee beverage of chilled coffee, milk, sweetener, and vanilla ice cream) will alter the shop's productivity. Her market research shows that Eiskaffee will bring in new customers and not cannibalize current demand. Assuming that the new equipment is purchased before Eiskaffee is added to the menu, Harald has developed new average daily demand and cost projections. The new equipment cost is $200, and the overhead cost is $350. Modified daily demands, as well…arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.