Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

Transcribed Image Text:HI

F.

R

mheducation.com/ext/map/index.html?_con%3con&external_browser%3D0&launchUrl=https%253A%252F%252Fnewconnect.mheduca.. h

= 我

Exam i

Saved

Help

Save & Exit

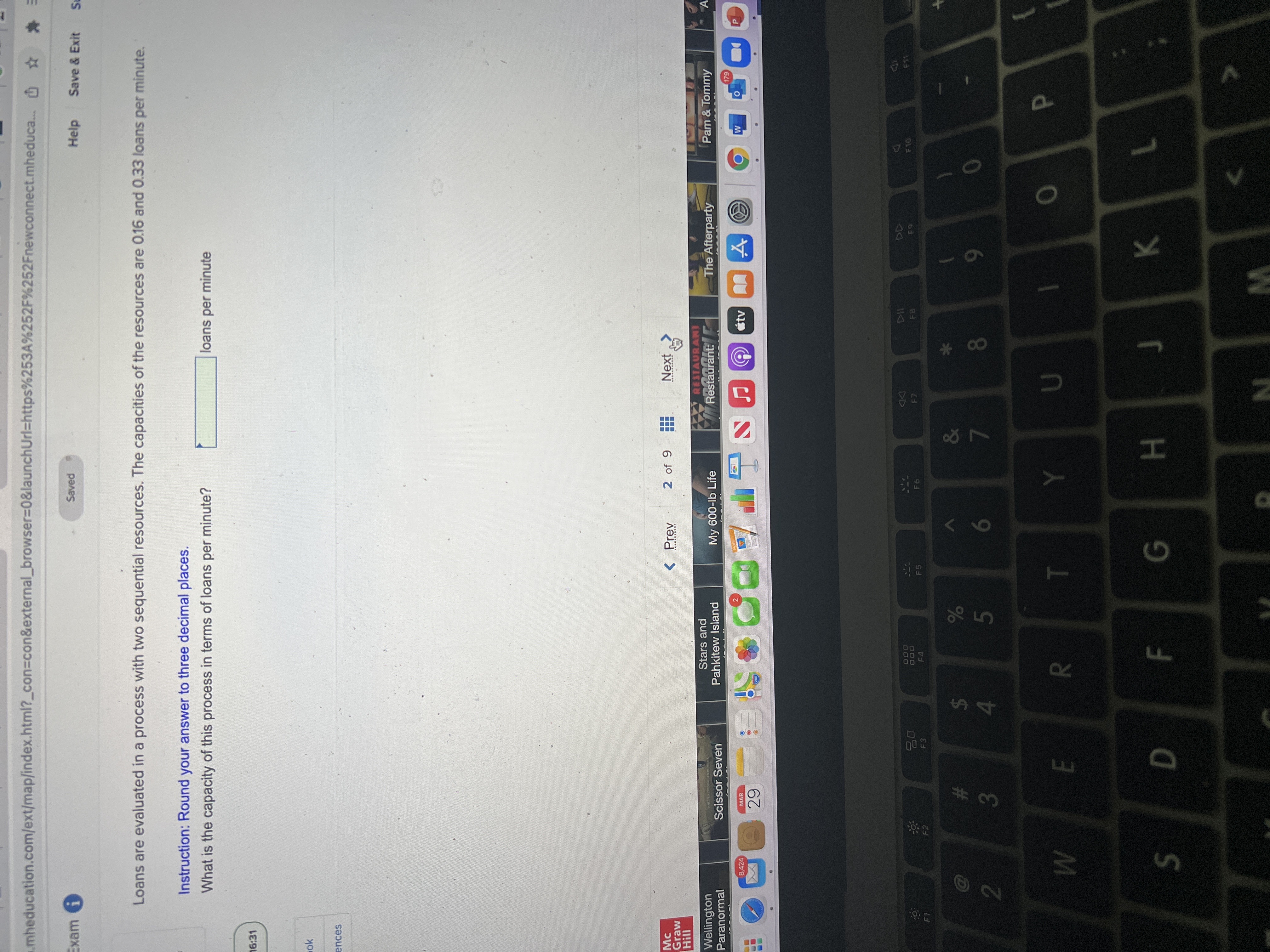

Loans are evaluated in a process with two sequential resources. The capacities of the resources are 0.16 and 0.33 loans per minute.

Instruction: Round your answer to three decimal places.

What is the capacity of this process in terms of loans per minute?

loans per minute

16:31

ok

ences

< Prev

2 of 9

Next>

Graw

II!H

RESTAURANT

Stars and

Pahkitew Island

Pam & Tommy

A.

Wellington

Paranormal

Restaurant:

The Afterparty

ANCTA DCINSL AnM Ststs

Scissor Seven

My 600-lb Life

67

8,424

O Ctv

MAR

P.

DD

F11

000

F 4

F8

OLA

F5

64

&

#3

3.

*

1

2$

5

7.

6

4.

9

2.

|

J

K

71

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- A production process at Brianna Bryant Manufacturing is shown in the figure below. The drilling operation occurs separately from, and simultaneously with, the sawing and sanding, which are independent sequential operations. A product needs to go through only one of the three assembly operations (the operations are in parallel). 6 units/hr 2.5 units/hr Sawing Sanding Q Assembly 0.8 units/hr Welding 5 units/hr Assembly 0.8 units/hr Drilling 2.1 units/hr a) is the bottleneck. b) The bottleneck time is minutes per unit (round your response to two decimal places). c) The throughput time of the overall system is minutes (round your response to two decimal places). Assembly 0.8 units/hr d) If the firm operates 11 hours per day, 20 days per month, the monthly capacity of the manufacturing process is units (enter your response as a whole number).arrow_forwardParty Apparel Inc. has 20 operators and work 8 hours a day, 5 days a week. They specialize in making formal party attire. The standard minute value to finish one of their lace formal gowns = 48 minutes. Assume that their actual capacity = max capacity. They just received an order for 1000 of these lace gowns. How many days will it take to complete this order? Round your answer to the nearest whole number, but do not round until your final answer. Group of answer choices 5 7 9 3arrow_forwardHi, I'm stuck on the remaining parts of this Operations Management problem. Please help. Thanks!arrow_forward

- Kingcade Corporation keeps careful track of the time required to fill orders. Data concerning a particular order appear below: Wait time Process time Inspection time Move time Queue time The throughput time was: Multiple Choice 33.1 hours 4.7 hours 28.4 hours 14.3 hours Hours 18.8 1.6 0.6 2.5 9.6arrow_forwardA work cell in a local manufacturer has a workstation with 4 machines that form a line (Machine 1-Machine 2-Machine 3-Machine 4). Each unit needs to pass through each machine in order to be completed. Each machine has a production capacity of four units per hour. What is the process time of the work cell in minutes per unit? 15 4 8 16arrow_forwardOrder 1 2 3 4 5 Time Since Order Arrived (hours ago) 3 1 0 6 5 You answered Sequence Order The due dates reflect the need for the order to be at its next operation. Develop separate schedules by using the FCFS and EDD rules. Compare the schedules on the basis of average flow time and average past due hours. Using the FCFS (first come, first served) decision rule for sequencing the orders, the order is Sequence Order Estimated Machine Time (hours) 15 9 7 10 3 1 5 Rule EDO FCFS 4 4 Using the EDD (earliest due date) decision rule for sequencing the orders, the order is (to resolve a tie, use order in which the orders were received) ¹2 1 4 2 3 Due Date (hours from now) 5 5 3 18 20 21 12 The average flow time and average past due hours for each option (enter your responses are real numbers rounded to two decimal place Average Flow Time Average Past Due Hoursarrow_forward

- A work cell is required to make 100 computerized diagnostic assemblies (for installation into hybrid automobiles) each day. The cell currently works an eight hour shift, of which seven hours is available for productive work. These assemblies require five operations, with times of 1.5, 1.8, 1.4, 1.5, and 1.9 minutes each. What is takt time for this cell? How many workers will be needed?arrow_forwardNote:- Do not provide handwritten solution. Maintain accuracy and quality in your answer. Take care of plagiarism. Answer completely. You will get up vote for sure.arrow_forwardIn Continuous manufacturing system, we need: Special purpose machines and Skilled labours ✔ Highly skilled labours and special machine tools General purpose machines and unskilled laborers. O Unskilled labours and semi automatic machinesarrow_forward

- A manufacturer's average WIP inventory for Part #2934 is 755 parts. The workstation produces parts at the rate of 295 parts per day. Use the Excel template Little's Law to find the average time a part spends in this workstation. Round your answer to two decimal places. daysarrow_forwardFollowing are products required for 22days period for 8 hours a day working hour. Product A = 12000 Product B = 8000 Product C = 6000 Produce levelled scheduling with small batch size. Show the calculationarrow_forwardA process is accomplished in 4 sequential steps- S1, S2, S3 and S4. The lead times (in minutes) and the number of resources for every step are indicated in the table below. Sub - Process Time (min) No of resources S1 12 1 S2 8 1 S3 16 1 S4 10 1 Assuming infinite demand, what is the process flow rate? {keep the time dimension as minutes for this, and answer in decimals). Hi all, I do not know how to answer this questions. Please review and advise. Thank youarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.