FINANCIAL ACCOUNTING

10th Edition

ISBN: 9781259964947

Author: Libby

Publisher: MCG

expand_more

expand_more

format_list_bulleted

Question

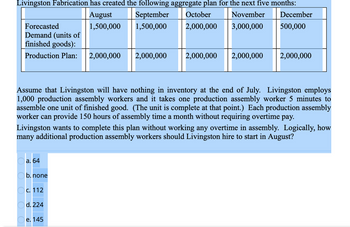

Transcribed Image Text:Livingston Fabrication has created the following aggregate plan for the next five months:

August

September

November

1,500,000

1,500,000

3,000,000

Forecasted

Demand (units of

finished goods):

Production Plan: 2,000,000

2,000,000

a. 64

October

2,000,000

b. none

c. 112

d. 224

e. 145

2,000,000 2,000,000

December

500,000

Assume that Livingston will have nothing in inventory at the end of July. Livingston employs

1,000 production assembly workers and it takes one production assembly worker 5 minutes to

assemble one unit of finished good. (The unit is complete at that point.) Each production assembly

worker can provide 150 hours of assembly time a month without requiring overtime pay.

2,000,000

Livingston wants to complete this plan without working any overtime in assembly. Logically, how

many additional production assembly workers should Livingston hire to start in August?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Similar questions

- Pridgeon Corporation plans to sell 23,000 units during August. If the company has 8,000 units on hand at the start of the month, and plans to have 9,000 units on hand at the end of the month, how many units must be produced during the month? O 24,000 O 22,000 O 32,000 O 31,000arrow_forwardWright Lighting Fixtures forecasts its sales in units for the next four months as follows: 20,000 22,000 19,500 18,000 March April May June Wright maintains an ending inventory for each month in the amount of two and one-half times the expected sales in the following month. The ending inventory for February (March's beginning inventory) reflects this policy. Materials cost $7 per unit and are paid for in the month after production. Labor cost is $11 per unit and is paid for in the month incurred. Fixed overhead is $19,000 per month. Dividends of $21,400 are to be paid in May. The firm produced 19,000 units in February. Complete a production schedule and a summary of cash payments for March, April, and May. Remember that production in any one month is equal to sales plus desired ending inventory minus beginning inventory. Note: Input all amounts as positive values except Beginning inventory values under Production Schedule which should be entered with a minus sign. Leave no cells blank…arrow_forwardCousin Eddy provides you with his sales forecast for the next four months: April May 750 June July 790 Sales (Units) 670 The company wants to end each month with ending finished goods Inventory equal to 40% of next month's forecasted sales. Finished goods inventory on April 1 is 268 units. Assume July's budgeted production is 700 units. In addition, each finished unit requires four pounds of raw materials and the company wants to end each month with raw materials inventory equal to 30% of next month's production needs. Beginning raw materials inventory for April was 842 pounds. Assume direct materials cost $5 per pound. Required: For May, how many units must be produced? (Hint: This is your production budget) Submit your answer below 700 with all work submitted via email.arrow_forward

- Carlos Cavalas, the manager of Echo Products' Brazilian Division, is trying to set the production schedule for the last quarter of the year. The Brazilian Division had planned to sell 69,850 units during the year, but by September 30 only the following activity had been reported: Inventory, January 1 Production Sales Inventory, September 30 The division can rent warehouse space to store up to 30,700 units. The minimum inventory level that the division should carry is 2,300 units. Mr. Cavalas is aware that production must be at least 5,940 units per quarter in order to retain a nucleus of key employees. Maximum production capacity is 45,700 units per quarter. Demand has been soft, and the sales forecast for the last quarter is only 20,900 units. Due to the nature of the division's operations, fixed manufacturing overhead is a major element of product cost. Required production Required: 1-a. Assume that the division is using variable costing. How many units should be scheduled for…arrow_forwardLi Company manufactures a product requiring 2 pounds of raw material for each finished unit. Raw materials inventory had a balance of on March 1 was 7,000 pounds. The company wants to maintain an ending inventory equal to 40% of the next month’s production needs. Production for March and April is projected to be 4,000 and 5,000 units, respectively. How many pounds of raw material must be purchased in March?arrow_forwardBalmforth Products, Inc. makes and sells a single product called a Bik. It takes three yards of Material A to make one Bik. Budgeted production of Biks for the next five months is as follows: February March. 14,000 units 15,500 units April.. 11,900 units May June. 12,600 units 14,500 units The company wants to maintain monthly ending inventories of Material A equal to 20% of the following month's production needs. On January 31, this target had not been attained since only 2,000 yards of Material A were on hand. The cost of Material A is $0.80 per yard. The company wants to prepare a Direct Materials Purchases Budget. The total cost of Material A to be purchased in February is: $45,200 O $34,320 O $42,900 O $39.440arrow_forward

- ed GreenThumb Organic Fertilizer Company plans to sell 210,000 units of finished product in July and anticipates a growth rate in sales of 3 percent per month. The desired monthly ending inventory in units of finished product is 90 percent of the next month's estimated sales. There are 189,000 finished units in inventory on June 30. Each unit of finished product requires 5 pounds of raw material at a cost of $1.35 per pound. There are 750,000 pounds of raw material in inventory on June 30. Required: 1. Compute the company's total required production in units of finished product for the entire three-month period ending September 30. Note: Round all intermediate calculations and your final answer to the nearest unit. 2. Independent of your answer to requirement 1, assume the company plans to produce 680,000 units of finished product in the three- month period ending September 30, and to have raw-material inventory on hand at the end of the three-month period equal to 25 percent of the…arrow_forwardOak Industrial has estimated that production for the next five quarters will be:. Production Information 1st quarter, 2020 44,100 units 2nd quarter, 2020 40,000 units 3rd quarter, 2020 48,200 units 4th quarter, 2020 37,600 units 1st quarter, 2021 45,700 units Finished units of production require 6 pounds of raw material per unit. The raw material cost is $7 per pound. There is $277,830 of raw material on hand at the beginning of the first quarter, 2020. Oak desires to have 15 percent of next quarter's material requirements on hand at the end of each quarter.Prepare quarterly direct materials purchases budgets for Oak Industrial for 2020.arrow_forwardThe following information is located in the production department of Mindy Ca Second First Quarter 14,300 Quarter Third Quarter Fourth Quarter 21,000 22,500 21,300 Units produced Other information found in the production department includes: Prior Year Ending RM Inventory Prior Year Ending A/P Pounds of RM per unit The ending raw material inventory per month should be 25% of the following month's production needs. The desired ending inventory for the fourth quarter is 3,700 pounds. Management plans to pay for 70% of the raw material purchases in the month bought and 30% in the following month. Direct Materials Budget Question: Given the data, the second quarter direct materials budget should be: Costs of Raw Materials per pound 5. $ Cost of DM Purchased: 10,725 11,775 First Second Quarter Quarter Third Quarter Fourth Quarter $ 4.50 $ 4.50 $ 4.50 $ 4.50arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning,

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning, Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning,

Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning, Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON

Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education

Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Accounting

Accounting

ISBN:9781337272094

Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.

Publisher:Cengage Learning,

Accounting Information Systems

Accounting

ISBN:9781337619202

Author:Hall, James A.

Publisher:Cengage Learning,

Horngren's Cost Accounting: A Managerial Emphasis...

Accounting

ISBN:9780134475585

Author:Srikant M. Datar, Madhav V. Rajan

Publisher:PEARSON

Intermediate Accounting

Accounting

ISBN:9781259722660

Author:J. David Spiceland, Mark W. Nelson, Wayne M Thomas

Publisher:McGraw-Hill Education

Financial and Managerial Accounting

Accounting

ISBN:9781259726705

Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting Principles

Publisher:McGraw-Hill Education