Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

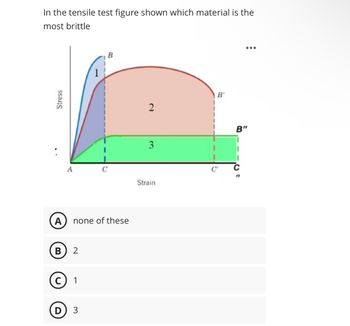

Brittle

Transcribed Image Text:In the tensile test figure shown which material is the

most brittle

Stress

1

B

2

B'

3

B"

A

Strain

A

none of these

B

2

(C) 1

D 3

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- A brass alloy to be used for a spring application must have a modulus of resilience of at least 0.75 MPa (110 psi). What must be its minimum yield strength? ( Ebrass = 97 ? 109 ???)arrow_forwardwhat is the equation and the units of measure for ductility?arrow_forward4. The mechanical properties of a given titanium alloy (Ti-6Al-4V) are E = 114 GPa, σy = 880 MPa and Kic = 75 MPa√m. What is the approximate plastic zone size? How large must a part be made if we want to test its K₁ using LEFM?arrow_forward

- Find the tensile toughness for a metal alloy with modulus of elasticity of 103 ???. Assume the plastic deformation begins at a strain value of 0.007 and fracture occurs at a strain value of 0.60. Assume also that fracture occurs at the point where necking begins and that the Κ and ? values are 1520 ??? and 0.15 respectively.arrow_forwardO The following engineering stress-strain data were obtained for a 0.2% C plain-carbon steel. (i) Plot the engineering stress-strain curve. (ii) Determine the ultimate tensile strength of the alloy. (iii) Determine the percent elongation at fracture. Engineering Engineering Engineering Engineering Stress Strain Stress Strain (ksi) (in./in.) (ksi) (in./in.) 76 0.08 30 0.001 75 0.10 55 0.002 73 0.12 60 0.005 69 0.14 68 0.010 65 0.16 72 0.020 56 0.18 74 0.040 51 0.19 75 0.060 (Fracture)arrow_forward3. Calculate the tensile modulus (G) of a 1-cm poly(methyl methacrylate) (CAS# 9011-14-7) rod with a tensile stress of 69.1 MPa and an elongation of 2.6%.arrow_forward

- I need the answer as soon as possiblearrow_forward296 8-10 A 0.505-in.-diameter metal bar with a 2-in. gage length o is subjected to a tensile test. The following measurements are made in the plastic region: 8-13 Chapter 8 Strain Hardening and Annealing Figure 8-23 shows a plot of the natural log- arithm of the true stress versus the natural logarithm of the true strain for a Cu-30% Zn sample tested in tension. Only the plastic portion of the stress strain curve is shown. Determine the strength coefficient K and the work-hardening exponent n. Change in Force Gage length Diameter (lb) (in.) (Al) (in.) 21 27,500 0.2103 0.4800 27,000 0.4428 0.4566 20 25,700 0.6997 0.4343 8-11 Determine the strain-hardening exponent for the metal. Is the metal most likely to be FCC, BCC, or HCP? Explain. A 1.33-cm-diameter metal bar with a 3-cm gage length (10) is subjected to a ten- sile test. The following measurements are made in the plastic region: In [True stress (Pa)] 18 16 -2.5 -2.0 -1.5 -1.0 -0.5 -0.0 In (True strain) Figure 8-23 The natural…arrow_forwardthis is material science questionarrow_forward

- FRACTURE TOUGHNESSarrow_forward2arrow_forwardThank you for answering this question. Please you specify each step as soon as possible. Good Luck! Thank you. Find the maximum biaxial stress,ox= -20, oy=-30, o > 0, that one can apply to a 60° lamina of glass/epoxy. Use maximum stress theory. Strength values of glass/epoxy: (6,Jult = 1062 MPa, (6,)ult= 610 MPa, (02)ult = 30 MPa, (o2Jult = 118 MPa, (T12)ult= 72 MPaarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY