Cornerstones of Cost Management (Cornerstones Series)

4th Edition

ISBN: 9781305970663

Author: Don R. Hansen, Maryanne M. Mowen

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Question

please fill out the table

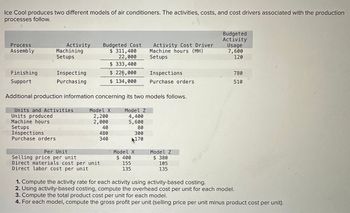

Transcribed Image Text:Ice Cool produces two different models of air conditioners. The activities, costs, and cost drivers associated with the production

processes follow.

Process

Assembly

Activity

Machining

Setups

Budgeted Cost

$ 311,400

22,000

$ 333,400

Finishing

Inspecting

$ 226,000

Support

Purchasing

$ 134,000

Budgeted

Activity

Activity Cost Driver

Machine hours (MH)

Usage

7,600

Setups

120

Inspections

780

Purchase orders

510

Additional production information concerning its two models follows.

Units and Activities

Units produced

Model X

Model Z

2,200

4,400

Machine hours

Setups

Inspections

Purchase orders

2,000

5,600

40

80

480

300

340

4170

Per Unit

Selling price per unit

Model X

$ 400

Model Z

$ 380

Direct materials cost per unit

155

105

Direct labor cost per unit

135

135

1. Compute the activity rate for each activity using activity-based costing.

2. Using activity-based costing, compute the overhead cost per unit for each model.

3. Compute the total product cost per unit for each model.

4. For each model, compute the gross profit per unit (selling price per unit minus product cost per unit).

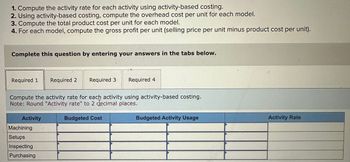

Transcribed Image Text:1. Compute the activity rate for each activity using activity-based costing.

2. Using activity-based costing, compute the overhead cost per unit for each model.

3. Compute the total product cost per unit for each model.

4. For each model, compute the gross profit per unit (selling price per unit minus product cost per unit).

Complete this question by entering your answers in the tabs below.

Required 1

Required 2 Required 3

Required 4

Compute the activity rate for each activity using activity-based costing.

Note: Round "Activity rate" to 2 decimal places.

Activity

Machining

Setups

Inspecting

Purchasing

Budgeted Cost

Budgeted Activity Usage

Activity Rate

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- Larsen, Inc., produces two types of electronic parts and has provided the following data: There are four activities: machining, setting up, testing, and purchasing. Required: 1. Calculate the activity consumption ratios for each product. 2. Calculate the consumption ratios for the plantwide rate (direct labor hours). When compared with the activity ratios, what can you say about the relative accuracy of a plantwide rate? Which product is undercosted? 3. What if the machine hours were used for the plantwide rate? Would this remove the cost distortion of a plantwide rate?arrow_forwardPlease see the pictures for info on questions 1 and 2. See below for format of questions 3 and 4: 3) Per Unit Direct Materials Direct Labor Overhead Product Cost per Unit Model X Model Z 4) Per Unit Selling Price Product cost per unit Gross Profit Model X Model Zarrow_forwardForner, Inc., manufactures and sells two products: Product Z1 and Product Z8. The company has an activity-based costing system with the following activity cost pools, activity measures, and expected activity Estimated Expected Activity Activity Overhead Activity Cost Pools Labor-related Measures Cost Product Z1 Product Z8 Total DLHS $112,190 40,440 609,770 600 2,000 Machine setups Оrder size 2,600 1,200 6, 200 setups 500 700 MHs 3,000 3,200 $762,400 The activity rate for the Machine Setups activity cost pool under activity-based costing is closest to: Multiple Cholce $203.26 per setup $190.55 per setup $122.97 per setup 92 F AQI 61 nere to search DELLarrow_forward

- Way Cool produces two different models of air conditioners. The company produces the mechanical systems in its components department. The mechanical systems are combined with the housing assembly In Its finishing department. The activities, costs, and drivers associated with these two manufacturing processes and the production support process follow. Process Activity Components Changeover Machining Setups Finishing Welding Support Inspecting Rework Purchasing Providing space Providing utilities Units produced Welding hours Batches Number of inspections Machine hours Setups Rework orders Purchase orders Required 1 Overhead Cost $ 559,650 411,510 74,000 $1,045,160 $ 288,640 257,600 55,000 601,240 $ $ 194,540 30,800 37,960 $ 263,300 Additional production Information concerning its two product lines follows. Required 2 Model 145 1,200 1,200 455 475 3,350 20 150 365 Driver Number of batches Machine hours Number of setups Required 3 Welding hours Number of inspections Rework orders Purchase…arrow_forwardForner, Incorporated, manufactures and sells two products: Product 21 and Product Z8. The company has an activity-based costing system with the following activity cost pools, activity measures, and expected activity: Activity Cost Pools Labor-related Machine setups Order size Multiple Choice Activity Measures DLHS setups MHS $7129 per MH Estimated Expected Activity Overhead Cost Product 21 Product 28 $ 109,600 51,690 808,470 $ 969,760 4,800 700 2,800 The activity rate for the Order Size activity cost pool under activity-based costing is closest to: 2,400 300 3,500 Total 7,200 1,000 6,300arrow_forwardForner, Inc., manufactures and sells two products: Product Z1 and Product Z8. The company has an activity-based costing system with the following activity cost pools, activity measures, and expected activity: Estimated Expected Activity Activity Cost Pools Activity Measures Overhead Cost Product Z1 Product Z8 Total Labor-related DLHs $ 112,190 600 2,000 2,600 Machine setups setups 40,440 500 700 1,200 Order size MHs 609,770 3,000 3,200 6,200 $ 762,400 The activity rate for the Order Size activity cost pool under activity-based costing is closest to: Multiple Choice $56.10 per MH $293.23 per MH $76.24 per MH $98.35 per MHarrow_forward

- Forner, Inc., manufactures and sells two products: Product Z1 and Product Z8. The company has an activity-based costing system with the following activity cost pools, activity measures, and expected activity: Expected Activity Estimated Activity Overhead Activity Cost Pools Measures Cost Product Z1 Product Z8 Total Labor-related $ 124,400 6,000 DLHS 3,000 9,000 Machine setups setups 58,660 700 600 1,300 Order size MHs 917,480 3,800 3,000 6,800 $1,100,540 The activity rate for the Order Sıze activity cost pool under activity-based costing is closest to: Multiple Cholce $59.53 per MH $193.87 per MH $143.55 per MH $134.92 per MHarrow_forwardThe following table presents the activities and activity drivers that LampPlus uses in manufacturing Product 1 and Product 2. Complete the table: Activity Design Preparation Machining Finishing Inspection Packaging Shipping Cost Activity Driver $ 39,060 Design time $ 67,650 Labor hours 105,200 Machine hours $ Batches Units Orders $ 12,720 Packages Driver Usage Prod. 1 840 3,130 209 76 Prod. 2 1,330 hours hours 300 56 Activity Rate $ $ $ $ /hour /hour 20 /hour 50 /batch 17 /unit 302 /order /package Activity Cost:Prod. 1 $ $ $ $ 34,430 31,200 Activity Cost:Prod. 2 9,690 $ 12,986 $ 19,720 3,600arrow_forwardSensor Systems manufactures an optical switch that it uses in its final product. The switch has the following manufacturing costs per unit: LOADING... (Click the icon to view the costs.) Direct materials $7.00 Direct labor 2.00 Variable overhead 8.00 Fixed overhead 6.50____________________________ Manufacturing product cost $23.50__________________________ _________________________________ LOADING... (Click the icon to view additional information.) Another company has offered to sell Sensor Systems the switch for $19.00 per unit. If Sensor Systems buys the switch from the outside supplier, the idle manufacturing facilities cannot be used for any other purpose, yet none of the fixed costs are avoidable. Prepare an outsourcing analysis to determine whether Sensor Systems should make or buy the switch. (For the Difference column, use a minus sign or parentheses only when the cost of outsourcing…arrow_forward

- Sanjay Company manufactures a product in a factory that has two producing departments, Assembly and Painting, and two support departments, S1 and S2. The activity driver for S1 is square footage, and the activity driver for S2 is number of machine hours. The following data pertain to Sanjay: Line Item Description SupportDepartmentsS1 SupportDepartmentsS2 ProducingDepartmentsAssembly ProducingDepartmentsPainting Direct costs $200,000 $140,000 $115,000 $96,000 Normal activity: Square footage — 500 1,875 625 Machine hours 337 — 3,200 12,800arrow_forwardGourmet Master, Inc., uses activity-based costing to determine the cost of its stainless steel ovens. Activity-based product cost information is as follows: Activity Activity-BaseUsage (hrs. per unit) x Activity Rateper Hour = Activity Cost Fabrication 0.75 $24.00 $18.00 Assembly 1.50 20.00 30.00 Inspection 0.30 25.00 7.50 Moving 0.25 12.00 3.00 Total activity cost per unit $58.50 These activities only include the labor portion of the cost. Fabrication is the cutting and shaping of metal to be used in the assembly of the ovens. If the metal is not fabricated properly, additional time is required during final assembly to trim and adjust the metal pieces to fit properly. This has been a problem in Assembly. Management proposes improvements in Fabrication requiring the fabrication work to be done slower, but more accurately. As a result, the time in fabrication will increase to an hour per unit. However, because of the additional care, the…arrow_forwardUnder an activity based costing system, what is the per-unit overhead cost of Zarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage LearningPrinciples of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage LearningPrinciples of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...

Accounting

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Cengage Learning

Principles of Accounting Volume 2

Accounting

ISBN:9781947172609

Author:OpenStax

Publisher:OpenStax College

Managerial Accounting: The Cornerstone of Busines...

Accounting

ISBN:9781337115773

Author:Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:Cengage Learning