FINANCIAL ACCOUNTING

10th Edition

ISBN: 9781259964947

Author: Libby

Publisher: MCG

expand_more

expand_more

format_list_bulleted

Question

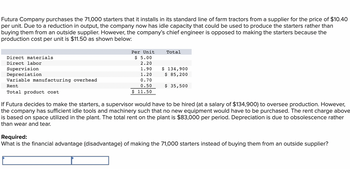

Transcribed Image Text:Futura Company purchases the 71,000 starters that it installs in its standard line of farm tractors from a supplier for the price of $10.40

per unit. Due to a reduction in output, the company now has idle capacity that could be used to produce the starters rather than

buying them from an outside supplier. However, the company's chief engineer is opposed to making the starters because the

production cost per unit is $11.50 as shown below:

Direct materials

Direct labor

Supervision

Depreciation

Variable manufacturing overhead

Rent

Total product cost

Per Unit

$ 5.00

2.20

1.90

1.20

0.70

0.50

$ 11.50

Total

$ 134,900

$ 85,200

$ 35,500

If Futura decides to make the starters, a supervisor would have to be hired (at a salary of $134,900) to oversee production. However,

the company has sufficient idle tools and machinery such that no new equipment would have to be purchased. The rent charge above

is based on space utilized in the plant. The total rent on the plant is $83,000 per period. Depreciation is due to obsolescence rather

than wear and tear.

Required:

What is the financial advantage (disadvantage) of making the 71,000 starters instead of buying them from an outside supplier?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

Knowledge Booster

Similar questions

- The Molding Division of Cotwold Company manufactures a plastic casing used by the Assembly Division. This casing is also sold to external customers for $36 per unit Variable costs for the casing are $12 per unit, and fixed cost is $5 per unit Cotwold executives would like for the Molding Division to transfer 19,000 units to the Assembly Division at a price of $30 per unit. Assume that the Molding Division has excess capacity, but the Assembly Division requires the casing to be made from a specific blend of plastics. This would raise the variable cost per unit to $33 Required: 1. Should the Molding Division accept the $30 transfer price proposed by management? 2. Determine the minimum transfer price that it will accept. 3. Determine the mutually beneficial transfer price so that the two divisions equally split the profits from the transferarrow_forwardLuca Inc. has received a special order for 2,000 units of its product at a special price of $75. The product normally sells for $100 and has the following manufacturing costs: Assume that Luca Inc. has sufficient capacity to fill the order without harming normal production and sales. If Luca Inc. accepts the order, what effect will the order have on the company's short-term profit? Per Unit Direct materials $30 Direct labor $20 Variable manufacturing overhead $15 Fixed manufacturing overhead $25 a. $50,000 decrease b. $30,000 increase c. $20,000 increase d. $30,000 decreasearrow_forwardFutura Company purchases the 66,000 starters that it installs in its standard line of farm tractors from a supplier for the price of $13.20 per unit. Due to a reduction in output, the company now has idle capacity that could be used to produce the starters rather than buying them from an outside supplier. However the company's chief engineer is opposed to making the starters because the production cost per unit is $14.10 as shown below. Direct materials Direct labor Supervision Depreciation Variable manufacturing overhead Rent Total product cost Per unit $ 7.00 2.50 1.90 1.40 0.70 0.60 $14.10 Total Financial (disadvantage) $125,400 $ 92,400* $ 39,600 If Futura decides to make the starters, a supervisor would have to be hired (at a salary of $125,400) to oversee production. However, the company has sufficient idle tools and machinery such that no new equipment would have to be purchased. The rent charge above is based on space utilized in the plant. The total rent on the plant is…arrow_forward

- Nonearrow_forwardCarla Vista Company has decided to introduce a new product that can be manufactured by either a capital-intensive method or a labour-intensive method. The manufacturing method will not affect the quality of the product. The estimated manufacturing costs under the two methods are as follows: Capital-Intensive Labour-Intensive Direct materials $5.50 per unit $10.75 per unit Direct labour $4.00 per unit $9.00 per unit Variable overhead $3.50 per unit $7.25 per unit Fixed manufacturing costs $2,423,040 $1,488,000 Carla Vista's market research department has recommended an introductory unit sales price of $32. The incremental selling expenses are estimated to be $481,920 annually, plus $2 for each unit sold, regardless of the manufacturing method. (a) * Your answer is incorrect. Calculate the estimated break-even point in annual unit sales of the new product if Carla Vista Company uses (1) the capital- intensive manufacturing method, or (2) the labour-intensive manufacturing method.arrow_forwardFutura Company purchases the 71,000 starters that it installs in its standard line of farm tractors from a supplier for the price of $12.70 per unit. Due to a reduction in output, the company now has idle capacity that could be used to produce the starters rather than buying them from an outside supplier. However, the company's chief engineer is opposed to making the starters because the production cost per unit is $12.90 as shown below: Direct materials Direct labor Supervision Depreciation Variable manufacturing overhead Rent Total product cost Per Unit $ 6.00 3.00 1.50 1.30 0.70 0.40 $12.90 Total $ 106,500 $ 92,300 $ 28,400 If Futura decides to make the starters, a supervisor would have to be hired (at a salary of $106,500) to oversee production. However, the company has sufficient idle tools and machinery such that no new equipment would have to be purchased. The rent charge above is based on space utilized in the plant. The total rent on the plant is $84,000 per period.…arrow_forward

- Asbury Coffee Enterprises (ACE) manufactures two models of coffee grinders. Personal and Commercial. The Personal grinders have a smaller capacity and are less durable than the Commercial grinders. ACE only recently began producing the Commercial model. Since the introduction of the new product, profits have been steadily declining, although sales have been increasing. The management at ACE believes that the problem might be in how the accounting system allocates costs to products. The current system at ACE allocates manufacturing overhead to products based on direct labor costs. For the most recent year, which is representative, manufacturing overhead totaled $1,929,000 based on production of 30,000 Personal grinders and 10,000 Commercial grinders. Direct costs were as follows: Direct materials Direct labor Cost Driver Number of production runs Quality tests performed Shipping orders processed Total overhead Management has determined that overhead costs are caused by three cost…arrow_forwardCrane Company has decided to introduce a new product. The new product can be manufactured by either a capital-intensive method or a labor-intensive method. The manufacturing method will not affect the quality of the product. The estimated manufacturing costs by the two methods are as follows. Direct materials Direct labor Variable overhead Fixed manufacturing costs (a) Capital-Intensive $6.00 per unit $7.00 per unit $4.00 per unit $3,200,000 Crane' market research department has recommended an introductory unit sales price of $40.00. The selling expenses are estimated to be $622,000 annually plus $2.00 for each unit sold, regardless of manufacturing method. 1. Capital-intensive manufacturing method. 2. Labor-intensive manufacturing method. Break-even point in units Labor-Intensive $7.00 per unit $10.00 per unit $5.50 per unit Calculate the estimated break-even point in annual unit sales of the new product if Crane Company uses the: $2,028,500 Capital-Intensive Labor-Intensivearrow_forwardFutura Company purchases 80,000 starters from a supplier at $9.90 per unit that it installs in farm tractors. Due to a reduction in output, the company now has enough idle capacity to produce the starters rather than buying them from the supplier. However, the company's chief engineer is opposed to making the starters because the production cost per unit is $10.80, as shown below: Direct materials Direct labor Supervision Depreciation Variable manufacturing overhead Per Unit Total $ 4.00 2.20 1.90 $ 152,000 1.50 $ 120,000 0.70 0.50 $ 10.80 $ 40,000 Rent Total product cost If Futura decides to make the starters, a supervisor would be hired (at a salary of $152,000) to oversee production. However, the company has sufficient idle tools and machinery such that no new equipment would have to be purchased. The rent charge above is based on space utilized in the plant. The total rent on the plant is $87,000 per period. Required: What is the financial advantage (disadvantage) of making the…arrow_forward

- Futura Company purchases the 66,000 starters that it installs in its standard line of farm tractors from a supplier for the price of $12.10 per unit. Due to a reduction in output, the company now has idle capacity that could be used to produce the starters rather than buying them from an outside supplier. However, the company's chief engineer is opposed to making the starters because the production cost per unit is $13.10 as shown below: Direct materials. Direct labor Supervision Depreciation Variable manufacturing overhead Rent Total product cost Per Unit $ 7.00 2.20 1.80 1.20 0.40 0.50 $ 13.10 Total $ 118,800 $ 79,200 $ 33,000 If Futura decides to make the starters, a supervisor would have to be hired (at a salary of $118,800) to oversee production. However, the company has sufficient idle tools and machinery such that no new equipment would have to be purchased. The rent charge above is based on space utilized in the plant and can't be avoided. The total rent on the plant is $81,000…arrow_forwardArtisan Metalworks has a bottleneck in their production that occurs within the engraving department. Jamal Moore, the COO, is considering hiring an extra worker, whose salary will be $54,000 per year, to solve the problem. With this extra worker, the company could produce and sell 2,900 more units per year. Currently, the selling price per unit is $26.00 and the cost per unit is $7.65. Direct materials $3.40 Direct labor 1.00 Variable overhead 0.45 Fixed overhead (primarily depreciation of equipment) 2.80 Total $7.65 Using the information provided, calculate the annual financial impact of hiring the extra worker. Profit $ 765 X Increasearrow_forwardAsbury Coffee Enterprises (ACE) manufactures two models of coffee grinders: Personal and Commercial. The Personal grinders have a smaller capacity and are less durable than the Commercial grinders. ACE only recently began producing the Commercial model. Since the introduction of the new product, profits have been steadily declining, although sales have been increasing. The management at ACE believes that the problem might be in how the accounting system allocates costs to products. The current system at ACE allocates manufacturing overhead to products based on direct labor costs. For the most recent year, which is representative, manufacturing overhead totaled $2,145,000 based on production of 30,000 Personal grinders and 10,000 Commercial grinders. Direct costs were as follows: Direct materials Direct labor Personal $ 1,451,400 1,038,000 Commercial $ 702,000 749,500 Total $ 2,153,400 1,787,500 Management has determined that overhead costs are caused by three cost drivers. These…arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning,

AccountingAccountingISBN:9781337272094Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.Publisher:Cengage Learning, Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning,

Accounting Information SystemsAccountingISBN:9781337619202Author:Hall, James A.Publisher:Cengage Learning, Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON

Horngren's Cost Accounting: A Managerial Emphasis...AccountingISBN:9780134475585Author:Srikant M. Datar, Madhav V. RajanPublisher:PEARSON Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education

Intermediate AccountingAccountingISBN:9781259722660Author:J. David Spiceland, Mark W. Nelson, Wayne M ThomasPublisher:McGraw-Hill Education Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Financial and Managerial AccountingAccountingISBN:9781259726705Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting PrinciplesPublisher:McGraw-Hill Education

Accounting

Accounting

ISBN:9781337272094

Author:WARREN, Carl S., Reeve, James M., Duchac, Jonathan E.

Publisher:Cengage Learning,

Accounting Information Systems

Accounting

ISBN:9781337619202

Author:Hall, James A.

Publisher:Cengage Learning,

Horngren's Cost Accounting: A Managerial Emphasis...

Accounting

ISBN:9780134475585

Author:Srikant M. Datar, Madhav V. Rajan

Publisher:PEARSON

Intermediate Accounting

Accounting

ISBN:9781259722660

Author:J. David Spiceland, Mark W. Nelson, Wayne M Thomas

Publisher:McGraw-Hill Education

Financial and Managerial Accounting

Accounting

ISBN:9781259726705

Author:John J Wild, Ken W. Shaw, Barbara Chiappetta Fundamental Accounting Principles

Publisher:McGraw-Hill Education