Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

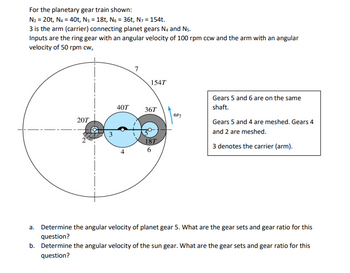

Transcribed Image Text:For the planetary gear train shown:

N₂ = 20t, N4 = 40t, N5 = 18t, №6 = 36t, N7 = 154t.

3 is the arm (carrier) connecting planet gears N4 and N5.

Inputs are the ring gear with an angular velocity of 100 rpm ccw and the arm with an angular

velocity of 50 rpm cw,

154T

40T

36T

W7

20T

3

18T

6

Gears 5 and 6 are on the same

shaft.

Gears 5 and 4 are meshed. Gears 4

and 2 are meshed.

3 denotes the carrier (arm).

a. Determine the angular velocity of planet gear 5. What are the gear sets and gear ratio for this

question?

b. Determine the angular velocity of the sun gear. What are the gear sets and gear ratio for this

question?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- For the planetary gear train shown: N₂ = 20t, N₁ = 40t, N₁ = 18t, N₁ = 36t, N₁ = 154t. 3 is the arm (carrier) connecting planet gears N, and Ns. Inputs are the ring gear with an angular velocity of 100 rpm cow and the arm with an angular velocity of 50 rpm cw, 1547 407 367 Gears 5 and 6 are on the same shaft. 207 Gears 5 and 4 are meshed. Gears 4 and 2 are meshed. 187 3 denotes the carrier (arm). a. Determine the angular velocity of planet gear 5. What are the gear sets and gear ratio for this question? b. Determine the angular velocity of the sun gear. What are the gear sets and gear ratio for this question?arrow_forwardI need the answer as soon as possiblearrow_forwardFor the simple gear train shown, calculate the torque ratio (VR). 130 rpm Wout Input Output Teeth N = 20 N = 45 %3D N = 95 %Darrow_forward

- The following data refer to two meshing involute gears of 20° pressure angle: Number of teeth on pinion 20, speed ratio = 2, speed of pinion = 250 rpm, module = 12 mm The addendum of each wheel is such that the path of approach and path of recess on each side are half of the maximum possible length. 1) Illustrate the value of addendum for both wheels, 2) Identify the length of arc of contact, and, 3) Formulate the free body diagrams for wheels in connection.arrow_forwardAnswer d and earrow_forwardA planetary gear train has Nsun = 30, Nplanet = 60, a module of 3 mm, a 20o pressure angle and is to transmit 5 kW. What torque can be delivered by the armature if the sun is driven at 1500 rpm and the ring is stationary?arrow_forward

- Question 1: The figure shows a 16T 20° straight bevel pinion driving a 32T gear, and the location of the bearing centerlines. Pinion shaft a receives 2.5 hp at 248 rev/min. Determine the bearing reactions at A and B if A is to take both radial and thrust loads. On-Screen Keyboard Esc 1 3. 4 5 6.arrow_forwardFor the complex gear train shown, calculate the torque ratio (TR). W2 = W3 W4 130 rpm N, = 45 N2 = 90 =80 N3 = 20arrow_forward3. For the following planetry gear train determine the following -Internal gear connected to drive shaft, 427 Sun gear: -Planet pinions, 127 Planet carrier connected to transmission Figure not to scale. N2 = 24 teeth, Input to Sun gear: w₂ = 100 rpm ccw, T₂ = 1000 lbf-in Input to Ring gear: ws = 240 rpm cw a. Determine the angular velocity of the carrier. (units and direction). b. Determine the torque on the arm.arrow_forward

- A 10 pitch pinion with 20 teeth mates with a gear having 80 teeth The pinion rotates at 3,000 RPM. The gear pair is to be installed in a rectangular housing where a minimum of 0.20 in clearance botween the gears and housing is requirod. Specify the dimensions X and Y as shown in tho figure below Note: This question requires a file attachinent, which can be pdf, ipeg. word, excol or power point. Show all your calculations. Handwritten calculations are acceptable. 0.20 in 0.20 In 0.20 in GEAR PINION N, 20arrow_forwardThe figure shows a double-reduction helical gearset. Pinion 2 is the driver, and it receives a torque of 1200 Ibf • in from its shaft in the direction shown. Pinion 2 has a normal diametral pitch of 8 teeth/in, 14 teeth, and a normal pressure angle of 20° and is cut right-handed with a helix angle of 30°. The mating gear 3 on shaft b has 36 teeth. Gear 4, which is the driver for the second pair of gears in the train, has a normal diametral pitch of 3 teeth/in, 15 teeth, and a normal pressure angle of 20° and is cut left-handed with a helix angle of 15°. Mating gear S has 45 teeth. Find the magnitude and direction of the force exerted by the bearings C and D on shaft b if bearing C can take only a radial load while bearing D is mounted to take both radial and thrust loads.arrow_forwardDesign a compound gear train with a +120:1 ratio and diametral pitch of 5 teeth/inch. Assume ø= 20° and avoiding interference between pinion and gear; i.e., use Table 9-5a page 495. Draw a front-view using circle template or compass and a top-view using a ruler. N2 = 15T N3 = 30T N4 = 15T N5 = 45T N6 = 16T N7 = 64T Ng = 16T N9 = 80T Answer: d2 = 3" d3 = 6" d4 = 3" ds = 9" do = 3.2" d7 = 12.8" dg = 3.2" d9 = 16"arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY