Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

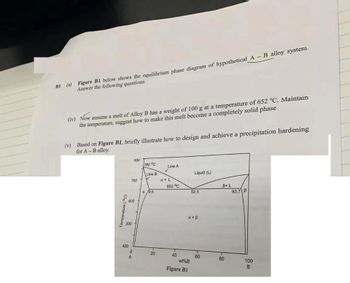

Transcribed Image Text:BI (a) Figure BI below shows the equilibrium phase diagram of hypothetical A - B alloy system.

Answer the following questions.

(iv) Now assume a melt of Alloy B has a weight of 100 g at a temperature of 652 °C. Maintain

the temperature, suggest how to make this melt become a completely solid phase

(v) Based on Figure B1, briefly illustrate how to design and achieve a precipitation hardening

for A-B alloy.

Temperature (°C)

8

700

600

500

400

800

OA

760 °C

Line B

a/9.5

20

Line A

a + L

650 °C

40

Liquid (L)

wt%B

Figure B1

52.5

a + B

60

B+L

80

93.7 B

100

B

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- In Figure 1 (phase diagram), an alloy composition of 95 wt% Mg and 5 wt% Al is cooled from 700 C to 475 C. An analysis of the resulting ε solid-phase composition reveals that it has a higher Mg content than is anticipated by the phase diagram.a) Explain why this might be the case and how your reasoning results in the higher-than-expected Mg content.b) Provide a sketch showing the likely distribution of Mg content within the volume of ε solid-phase.arrow_forwardReferring to Figure 1, please answer the following [NOTE: SHOW YOUR WORK on Figure 1]:a. provide the specific name for the phase boundary lines denoted by A and B. b. identify the phases present at equilibrium in the phase fields denoted by C, D, and E. c. identify the specific name for the point denoted by F. d. What is the maximum solid solubility of Mg in Al? At what temperature does it occur? e. An Al-Mg alloy (10 wt% Mg, 90 wt% Al) is heated slowly (to insure equilibrium) from a temperature of 200 C: i. At what temperature does the first liquid phase form? ii. What is the composition of the liquid phase at the temperature in part i.? iii. At what temperature does complete melting (no solid phase remaining) occur? iv. What is the composition of the last solid remaining prior to complete melting? f. Using the equilibrium phase diagram of Figure 1, identify the phases present, their compositions, and their relative mass fractions at equilibrium for a 70 wt% Mg – 30 wt% Al…arrow_forwardGiven the equilibrium phase diagram (a) below, briefly describe the mechanisms of precipitation hardening/strengthening of an aluminium alloy making reference to the transitions shown in (b) below to X, X to A, X to D, A to B and A to C. а +0 D B Time (a) (b) - anedua Temperaturearrow_forward

- Consider the binary alloy phase diagram shown schematically below. The left-hand side denotes phase a, and the right-hand side the phase ß. The intermediate region is a coexistence regime with both a and ß phases. The three points 1, 2 and 3 in the coexistence region are at 22.8 wt% A, 28.2 wt% A, and 33.7 wt % A respectively. If the points on the phase boundaries L and R are at 20 wt% A and 39 wt % A, respectively, what is the fraction of a phase at 1, 2 and 3? (This question has only one correct answer) T(°C) A-B binary alloy 1400 Coexistence region 3 1 2 1100 B 20 % 40 % Weight % Aarrow_forwardUsing the isothermal transformation diagram given in Figure 2 for a specific material composition to answer the following (this is NOT an Fe-C steel!). NOTE: Assume that you begin with a single-phase sample of α at 790 C.a. What temperature on the diagram corresponds to the α-to-γ phase transformation temperature that would be found on an equilibrium phase diagram? Explain your answer. b. What temperature would provide the most rapid, isothermal phase transformation of α to γ? What would be the minimum time from onset of the phase transformation to its completion? c. On Figure 2, draw and label a cooling schedule (from 790 C) that will produce a single-phase α material at 100 C. How does the thickness of the piece of material influence your ability to create a single-phase α structure? d. Why does the time to initiate phase transformation become smaller as the temperature is reduced within the temperature range above the “nose” of the TTT diagram? Be specific, what process is…arrow_forwardCorrect and complete solution pleasearrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY