Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

question and answer attached.

could someone show clearer working and reasoning behind solotion

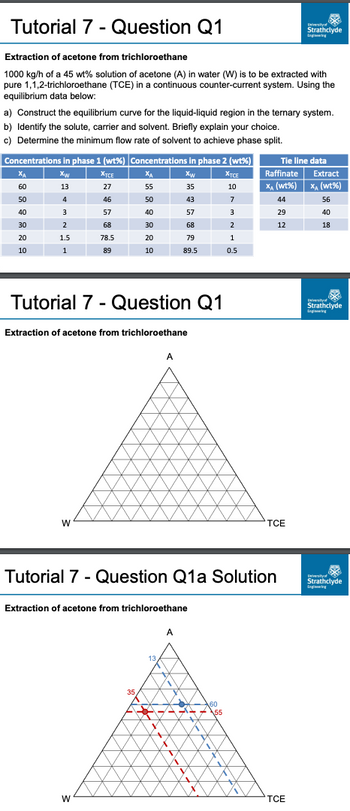

Transcribed Image Text:Tutorial 7 - Question Q1

Extraction of acetone from trichloroethane

1000 kg/h of a 45 wt% solution of acetone (A) in water (W) is to be extracted with

pure 1,1,2-trichloroethane (TCE) in a continuous counter-current system. Using the

equilibrium data below:

a) Construct the equilibrium curve for the liquid-liquid region in the ternary system.

b) Identify the solute, carrier and solvent. Briefly explain your choice.

c) Determine the minimum flow rate of solvent to achieve phase split.

Concentrations in phase 1 (wt%) Concentrations in phase 2 (wt%)

Xw

Xw

13

35

4

3

2

1.5

1

ХА

60

50

40

30

20

10

XTCE

27

46

57

68

78.5

89

W

Tutorial 7 - Question Q1

ХА

55

50

40

30

20

10

Extraction of acetone from trichloroethane

W

35

Extraction of acetone from trichloroethane

12

13.

A

30-

x

+

43

57

68

79

89.5

Tutorial 7 - Question Q1a Solution

A

X

A

V

4

K

X

60

A

55

XTCE

10

X

7

3

2

1

0.5

A

University of

Strathclyde

Engineering

Tie line data

Raffinate

Extract

X₁ (wt%) X₁ (wt%)

44

56

29

40

12

18

TCE

TCE

University of

Strathclyde

☆

University

Strathclyde

Engineering

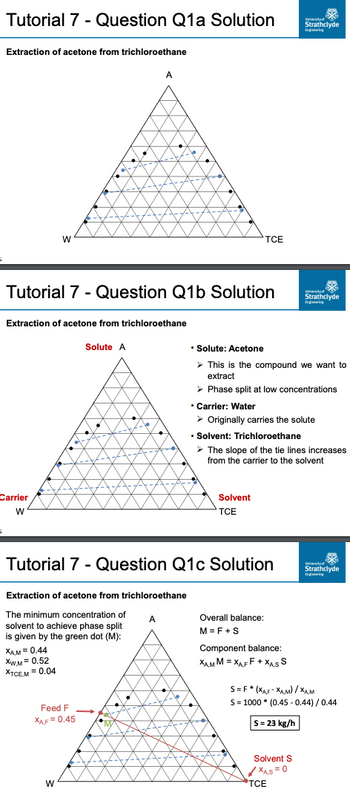

Transcribed Image Text:Tutorial 7 - Question Q1a Solution

Extraction of acetone from trichloroethane

W

Carrier

W

Tutorial 7 - Question Q1b Solution

Extraction of acetone from trichloroethane

d

4

W

Solute A

Feed F

XAF 0.45

.

.

Extraction of acetone from trichloroethane

The minimum concentration of

solvent to achieve phase split

is given by the green dot (M):

XAM = 0.44

XW.M= 0.52

XTCEM = 0.04

A

(.)

.

A

• Solute: Acetone

Tutorial 7 - Question Q1c Solution

TCE

. Solvent: Trichloroethane

This is the compound we want to

extract

> Phase split at low concentrations

• Carrier: Water

➤ Originally carries the solute

Solvent

TCE

The slope of the tie lines increases.

from the carrier to the solvent

Overall balance:

M=F+S

Component balance:

XAM M=XAFF+XAS S

Carathclyde

University of

University of

Strathclyde

Solvent S

✓✓XAS=0

TCE

S=F* (XAF-XAM)/XAM

S = 1000 (0.45-0.44) / 0.44

S = 23 kg/h

University of

Strathclyde

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 5 steps with 3 images

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

could you touch further on the last slide, where does the mixing point come from and also tie lines ?

Solution

by Bartleby Expert

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

could you touch further on the last slide, where does the mixing point come from and also tie lines ?

Solution

by Bartleby Expert

Knowledge Booster

Similar questions

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The