Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

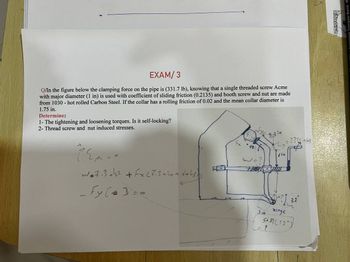

Transcribed Image Text:EXAM/3

Q/In the figure below the clamping force on the pipe is (331.7 lb), knowing that a single threaded screw Acme

with major diameter (1 in) is used with coefficient of sliding friction (0.2135) and booth screw and nut are made

from 1030 - hot rolled Carbon Steel. If the collar has a rolling friction of 0.02 and the mean collar diameter is

1.75 in.

Determine:

1- The tightening and loosening torques. Is it self-locking?

2- Thread screw and nut induced stresses.

w*7.3+² + Fx (7.3+1+6+43))

Fy (3

10

3.3 in

Fx 421

3.3 (sin(

'in

3 in

?) 32°

hinge

"Sin (12")

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Similar questions

- In the figure below the clamping force on the pipe is (331.7 lb), knowing that a single threaded screw Acme with major diameter (1 in) is used with coefficient of friction (0.2135). If booth screw and nut are made from 1030 - hot rolled Carbon Steel. Determine: 1- The tightening and loosening torques. 2- Thread screw and nut shear safety factors in case of double threads are in engagement. 3.3 in 2 7.2 in 32 3 in hingearrow_forwardIn the figure below the clamping force on the pipe is (331.7 lb), knowing that a single threaded screw Acme with major diameter (1 in) is used with coefficient of sliding friction (0.2135) and booth screw and nut are made from 1030- hot rolled Carbon Steel. If the collar has a rolling friction of 0.02 and the mean collar diameter is 1.75 in. Determine: 1- The tightening and loosening torques. Is it self-locking? 2- Thread screw and nut induced stresses. PEM.. w* 7.3 +4² +Fx (7.3 +²2₂ +6+43)] _Fy (3) Fx W=? 3.3 in L₁ 3 in = 3.3 (sin(4 32 hinge 552 (32)arrow_forwardHi, Please help with the question in the image, also if you need more points then please feel free, thanksarrow_forward

- If you are Sure then Only Attempt.arrow_forwardSituational Problem ( 3 - 4) An automobile engine develops 33.5 hp at 1,000 rpm. The clutch used to transmit this power in a single plate clutch with two pairs of contact surfaces. The coefficient of friction is 0.4 and the mean diameter of the disk is to be 190 mm. The average normal stress on the clutch lining is 120 kPa. 3. Determine the axial force to engage the clutch based on uniform wear. A. 1.57 kN B. 3.14 kN C. 5.28 kN D. 7.46 kNarrow_forwardQ1) The V thread of a screw jack has a single start with out side diameter 40 mm and 6 mm pitch. The angle of V is 55° and the load is carried on a swivel head of mean diameter 60 mm. the coefficient of friction between the nut and screw is 0.16 and that between the swivel head and the spindle is 0.1. Calculate the load required to be applied at the end of two levers each of effective length of 500 mm to raise an axial load of 1 KN and the efficiency of the lifting.arrow_forward

- 1. A collar is fitted as a tight fit on a solid shaft. In the measurement made before assembly, the outer diameter of the ring is dga=159.97 mm, the inner diameter is dgi= 100.03 mm, and the outer diameter of the shaft is dma= 100.048 mm. After assembly; a. What is the surface pressure between the shaft and the ring? b. What is the maximum shear stress? Given: Material pair steel/steel P E=2.1x10$ N/mm?, Tmax (1-Q¿)arrow_forwardi need the answer quicklyarrow_forwardInformation about the clamp assembly in the figure is given below. Thread diameter 12 mm, root diameter 10.16 mm, pitch 1.5 mm, screw profile angle 2α=60, friction surface of table A diameter 10 mm, friction between plate A-screw end surface coefficient 0.15 and screw-nut friction coefficient 0.15 is given. If a hand force of 200N is applied to the vise arm, if applied, a) How much force is applied to the clamped part. b) Calculate the efficiency of the vise.arrow_forward

- 1- A bush roller chain drive is used to transmit 4 kW of power from the driving shaft on a hydraulic motor runs at 1200 r.p.m to the driven shaft which runs at 350 r.p.m. The drive is required to operate continuously with drop lubrication and driven machine is such that load can be regarded as fairly constant. Design the chain drive by calculating leading dimensions, number of teeth on the sprockets taking into account that the available distance between the two shafts centers is 400mm + 4% no more no less.arrow_forwardSolve the following problem (NOTE: Use any reasonable DATA not given in the problem.)arrow_forwardsolve show all stepsarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY