Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

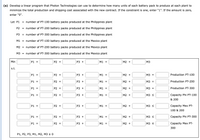

| (b) | Solve the linear program developed in part (a), to determine the optimal production plan. If the amount is zero, enter "0". | ||||||||||||||

|

|||||||||||||||

| Total Cost = __________$ | |||||||||||||||

| (c) | Use sensitivity analysis to determine how much the production and/or shipping cost per unit would have to change to produce additional units of the PT-100 in the Philippines plant. | ||||||||||||||

| If required, round your answer to two decimal digits. | |||||||||||||||

| At least $ _________/ unit. | |||||||||||||||

| (d) | Use sensitivity analysis to determine how much the production and/or shipping cost per unit would have to change to produce additional units of the PT-200 in the Mexico plant. | ||||||||||||||

| If required, round your answer to two decimal digits. | |||||||||||||||

| At least $ _______/ unit. |

Transcribed Image Text:Photon Technologies, Inc., a manufacturer of batteries for mobile phones, signed a contract with a large electronics manufacturer to produce three models of lithium-ion battery packs for a new line of phones. The contract calls for the following production quantities:

- **PT-100:** 200,000 units

- **PT-200:** 100,000 units

- **PT-300:** 150,000 units

Photon Technologies can manufacture the battery packs at manufacturing plants located in the Philippines and Mexico. The unit cost of the battery packs differs at the two plants due to differences in production equipment and wage rates. The unit costs for each battery pack at each manufacturing plant are listed below:

| Product | Philippines | Mexico |

|---|---|---|

| PT-100 | $0.95 | $0.98 |

| PT-200 | $0.98 | $1.06 |

| PT-300 | $1.34 | $1.15 |

The PT-100 and PT-200 battery packs are produced using similar production equipment available at both plants. However, each plant has a limited capacity for the total number of PT-100 and PT-200 battery packs produced. The combined PT-100 and PT-200 production capacities are 175,000 units at the Philippines plant and 160,000 units at the Mexico plant. The PT-300 production capacities are 75,000 units at the Philippines plant and 100,000 units at the Mexico plant. The cost of shipping from the Philippines plant is $0.15 per unit, and from the Mexico plant is $0.12 per unit.

Transcribed Image Text:**Linear Programming for Battery Pack Production Optimization**

Photon Technologies needs to determine the optimal number of battery packs to produce at each plant to minimize production and shipping costs. To achieve this, a linear program model is being developed.

**Variables Definition:**

- **P1** = Number of PT-100 battery packs produced at the Philippines plant

- **P2** = Number of PT-200 battery packs produced at the Philippines plant

- **P3** = Number of PT-300 battery packs produced at the Philippines plant

- **M1** = Number of PT-100 battery packs produced at the Mexico plant

- **M2** = Number of PT-200 battery packs produced at the Mexico plant

- **M3** = Number of PT-300 battery packs produced at the Mexico plant

**Objective:**

- Minimize the total number of battery packs produced: P1 + P2 + P3 + M1 + M2 + M3

**Subject to Constraints:**

1. **Production Constraints:**

- \( P1 + M1 =\) Production PT-100

- \( P2 + M2 =\) Production PT-200

- \( P3 + M3 =\) Production PT-300

2. **Capacity Constraints:**

- \( P1 + P2 + M1 + M2 \leq\) Capacity for Philippines PT-100 & 200

- \( P1 + P2 + M1 + M2 \leq\) Capacity for Mexico PT-100 & 200

- \( P3 + M3 \leq\) Capacity for Philippines PT-300

- \( P3 + M3 \leq\) Capacity for Mexico PT-300

3. **Non-negativity Constraints:**

- \( P1, P2, P3, M1, M2, M3 \geq 0\)

This linear program will help Photon Technologies decide on the number of units to produce at each location while minimizing associated costs.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- please answer within 30 minutes.arrow_forwardShoes Ltd. manufactures three items: Sneakers, Takkies and Sandals. The table below contains information regarding these products: Sneakers (R/ unit) Takkies (R/ unit) Sandals (R/ unit) Material cost 60 75 40 Labour cost 24 68 42 Variable overhead cost 7 12 16 Fixed overhead cost 36 23 11 Selling price per unit 870 990 650 Volume of production 12 000 28 500 31 200 Fixed overheads are allocated to products based on direct labour hours. Direct labour hours are constrained and therefore limited to 140 000 hours. The direct labour rate is R25 per hour. w Required: Q.3.1 Calculate the contribution margin per labour hour and then rank the products in order of profitability. Q.3.2 Calculate the number of units of each product that needs to be manufactured toarrow_forwardq9- Booktopia, a bookstore in Melbourne, has a new collection of 200 books to sell. The management staff need to make a decision about which price range to sell for. The prices need to be balanced between making a maximum profit, which might discourage sales, and making a minimum profit which will increase the number of books sold. The data is in the screenshot Use the 2 variable data table method to calculate the total profit for different percentages of books sold with different highest prices. Choose the correct results to fill in the table below. Note that you may need to adjust the Data Table in the screenshot on excel, including the percentages and prices.arrow_forward

- L. Houts Plastics is a large manufacturer of injection-molded plastics in North Carolina. An investigation of the company's manufacturing facility in Charlotte yields the information presented in the table below. How would the plant classify these items according to an classification system? (Round dollar volume to the nearest whole number and percentage of dollar volume to two decimal places.) Item number 2349 should be classified as Item Code Item number 8210 should be classified as 1289 2347 2349 2363 2394 2395 6782 7844 8210 8310 9111 L. Houts Plastics Charlotte Inventory Levels Value Dollar ($/unit) Volume Avg. Inventory (units) 400 300 120 75 89223 co 60 30 20 12 7 6 3.75 4.00 2.50 1.50 1.75 2.00 1.15 2.05 1.80 2.00 3.00 1,200 300 105 23 25 14 18 3,372 % of Dollar Volume 35.59 8.90 3.11 0.68 0.73 0 0.42 0.53 For the following three questions, consider only items 1289, 2349, and 8210 from the above table for relative classification (these are some of the items for which you…arrow_forwardPlease answer D & E.arrow_forwardThe table above provides the aggregate plan of production by a firm. It is known that the firm uses a level plan with lost sales, i.e., without backorders. Given this information, what is the number in the cell that says xx?arrow_forward

- 5 X Month fx B C D E F G H Problem 7 Given the following forecast and cost information, determine the total cost of a chase plan that uses regular time production output of 400 units per month, overtime is used when needed up to a maximum of 40 units per month, and subcontracting is used if additional units are needed to meet the forecast. 1 2 3 45 6 Font Forecast Cover 440 400 450 460 480 490 Totals Problem 6 Accessibility: Investigate √5 Level Production. Production Overtime Problem 7 Alignment Subcontr acting Inventory Total Holding Cost Problem 8 Problem 18 F Number Ty Costs Formatting Table Styles Production Costs. Regular Overtime Subcontracting $ 555 E 50.00 65.00 75.00 Regular Time Overtime Subcontracting Total Cost Marrow_forwardStandard Costing; Variance Analysis; Strategic Considerations In a Wall Street Journalarticle, the author notes that various retailers in the United States (e.g., Meijer, Gap, and OfficeDepot) are turning to consulting firms, such as Accenture, to develop engineered labor standards forcashiers and other retail workers. Monitoring labor-hour consumption (i.e., labor efficiency) undersuch standards involves timing from the first scan of an item in a customer’s purchase to the production of a sales receipt for the customer. A commentator for Meijer states that the system now in usehas enabled the company to more efficiently staff stores while concomitantly increasing customerservice ratings. A representative from another client of Accenture states that the new system allowsthe retailer to determine how many workers to schedule at a given time, resulting in a labor-costreduction of approximately 8%. Engineered standards were developed many years ago in a manufacturing environment, at…arrow_forwardThe Porsche Club of America sponsors driver education events that provide high-performance driving instruction on actual race tracks. Because safety is a primary consideration at such events, many owners elect to install roll bars in their cars. Deegan Industries manufactures two types of roll bars for Porsches. Model DRB is bolted to the car using existing holes in the car's frame. Model DRW is a heavier roll bar that must be welded to the car's frame. Model DRB requires 20 pounds of a special high alloy steel, 40 minutes of manufacturing time, and 60 minutes of assembly time. Model DRW requires 25 pounds of the special high alloy steel, 100 minutes of manufacturing time, and 40 minutes of assembly time. Deegan's steel supplier indicated that at most 36,000 pounds of the high-alloy steel will be available next quarter. In addition, Deegan estimates that 2,000 hours of manufacturing time and 1,700 hours of assembly time will be available next quarter. The profit contributions are $200…arrow_forward

- 19. SPRAY-PAINT INVENTORY The Graphic Hobby House made purchases of assorted colors of spray paint during the year as follows. Beginning inventory 200 cans at $2.20 March 400 cans at $2.40 May 700 cans at $2.00 August 500 cans at $2.30 November 300 cans at S2.60 At the end of the year, they had 450 cans of spray paint in stock. (a) Find the inventory value using the weighted-average method. (b) Find the inventory value using the FIFO method. (c) Find the inventory value using the LIFO method.arrow_forwardGreen Gardens' owner has asked your advice about a possible problem at his business. Over the last 6 months the large-sized lawn and garden inventory (ie, tables, chairs, planters, etc.) has appeared to be short. The inventory records that employees use to determine what is on hand show that more inventory is available than can actually be located. This has cause frustration and mis-trust in the inventory records for the sales employees. The owner realizes that the problem is bigger than just frustrated employees. He is afraid that inventory is being stolen, a problem he didn't think possible given that these are large items that are not easily moved. Requirements: Provide the owner with two internal controls that he could implement to reduce the likelihood of theft of the lawn and garden inventory.arrow_forwardSpecialty Toys, Inc., sells a variety of new and innovative children's toys. Management learned that the preholiday season is the best time to introduce a new toy, because many families use this time to look for new ideas for December holiday gifts. When Specialty discovers a new toy with good market potential, it chooses an October market entry date. In order to get toys in its stores by October, Specialty places one-time orders with its manufacturers in June or July of cach year. Demand for children's toys can be highly volatile. If a new toy catches on, a sense of shortage in the marketplace often increases the demand to high levels and large profits can be realized. However, new toys can also flop, leaving Specialty stuck with high levels of inventory that must be sold at reduced prices. The most important question the company faces is deciding how many units of a new toy should be purchased to meet anticipated sales demand. If too few are purchased, sales will be lost; if too many…arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.