Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

thumb_up100%

I need help with the constraint and how to solve the probelm on excel

**Map Explanation:**

The map illustrates the logistics network across Ohio with the following key points:

- **Factories**:

- **Toledo** (marked by a red dot in the northwest)

- **Cleveland** (marked by a red dot in the northeast)

- **Steubenville** (marked by a red dot in the east)

- **Distribution Centers**:

- **Marion** (marked by a red dot in the center-north)

- **Newark** (marked by a red dot in the center-east)

- **Retail Stores**:

- **Columbus** (marked by a red dot in the center)

- **Dayton** (marked by a red dot in the southwest)

These locations will serve as the points in your network model to facilitate the efficient transportation and distribution of products within Ohio.](https://content.bartleby.com/qna-images/question/45f8be63-7838-4070-8d43-b73244fc7649/9b91a44a-0243-4134-8342-db9fa0ab71ba/qx39a4_thumbnail.png)

Transcribed Image Text:### Problem 2 – Network Model

You've just started a job at a company that produces and distributes products around Ohio. Your boss is struggling with the logistics of shipping your products in the most cost-effective way possible. She has tasked you with creating a network model in Excel to help her out.

Your logistics network consists of three factories, two distribution centers, and two retail stores. The factories are located in Toledo, Cleveland, and Steubenville, OH. The distribution centers are located in Marion and Newark, OH. The retail locations are located in Columbus and Dayton, OH. A map of these nodes can be seen below:

**Map Explanation:**

The map illustrates the logistics network across Ohio with the following key points:

- **Factories**:

- **Toledo** (marked by a red dot in the northwest)

- **Cleveland** (marked by a red dot in the northeast)

- **Steubenville** (marked by a red dot in the east)

- **Distribution Centers**:

- **Marion** (marked by a red dot in the center-north)

- **Newark** (marked by a red dot in the center-east)

- **Retail Stores**:

- **Columbus** (marked by a red dot in the center)

- **Dayton** (marked by a red dot in the southwest)

These locations will serve as the points in your network model to facilitate the efficient transportation and distribution of products within Ohio.

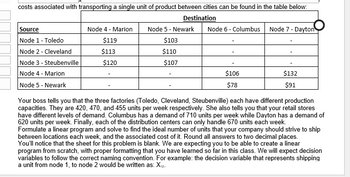

Transcribed Image Text:### Transportation Cost Optimization Problem

In this problem, we are focusing on optimizing the transportation costs associated with shipping products between different cities. The table below details the transportation costs for a single unit of product between various source nodes and destination nodes.

#### Cost Table

| Source | Node 4 - Marion | Node 5 - Newark | Node 6 - Columbus | Node 7 - Dayton |

|--------------|------------------|------------------|-------------------|------------------|

| **Node 1 - Toledo** | $119 | $103 | - | - |

| **Node 2 - Cleveland** | $113 | $110 | - | - |

| **Node 3 - Steubenville** | $120 | $107 | - | - |

| **Node 4 - Marion** | - | - | $106 | $132 |

| **Node 5 - Newark** | - | - | $78 | $91 |

Note: A dash ("-") indicates that no direct shipping cost is available between those nodes.

### Problem Description

Your task involves optimizing the shipping schedule and costs between these nodes. There are three factories located in:

- Toledo

- Cleveland

- Steubenville

The production capacities for these factories are as follows:

- **Toledo:** 420 units per week

- **Cleveland:** 470 units per week

- **Steubenville:** 455 units per week

The demand at the retail stores in different locations is also provided:

- **Columbus:** 710 units per week

- **Dayton:** 620 units per week

Each distribution center can handle a maximum of 670 units per week.

### Problem-solving Task

Formulate a linear program to determine the optimal number of units your company should ship between these locations to minimize costs. Compute the associated cost and present your answers to two decimal places.

### Instructions for Formulation

1. **Decision Variables:**

- Represent shipping from node \( i \) to node \( j \) using \( X_{ij} \).

- Example: Shipping a unit from Node 1 (Toledo) to Node 2 (Cleveland) will be denoted as \( X_{12} \).

2. **Objective Function:**

- Minimize the total transportation cost.

3. **Constraints:**

- Production

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 4 images

Knowledge Booster

Similar questions

- Gerald Glynn manages the Michaels Distribution Center. After careful examination of his database information, he has determined the daily requirements for part-time loading dock personnel. The distribution center operates 7 days a week, and the daily part-time staffing requirements are Day M T W Th F S Su Requirements 7 3 5 5 6 2 2 Find the minimum number of workers Glynn must hire. Prepare a workforce schedule for these individuals so that each will have 2 consecutive days off per week and all staffing requirements will be satisfied. Give preference to the S-Su pair in case of a tie. (Note: If there is a tie that cannot be broken by following the preference to the S-Su pair, choose the pair closest to the beginning of the considered week.) Part 2 The minimum number of workers is _________workers. (Enter your response as a…arrow_forwardI need help finding the answer for this problemarrow_forwardA renowned chocolatier, Francesco Schroeder, makes three kinds of chocolate confectionery: artisanal truffles, handcrafted chocolate nuggets, and premium gourmet chocolate bars. He uses the highest quality of cacao butter, dairy cream, and honey as the main Ingredients. Francesco makes his chocolates each morning, and they are usually sold out by the early afternoon. For a pound of artisanal truffles, Francesco uses 1 cup of cacao butter, 1 cup of honey, and 1/2 cup of cream. The handcrafted nuggets are milk chocolate and take 1/2 cup of cacao, 2/3 cup of honey, and 2/3 cup of cream for each pound. Each pound of the chocolate bars uses 1 cup of cacao butter, 1/2 cup of honey, and 1/2 cup of cream. One pound of truffles, nuggets, and chocolate bars can be purchased for $35, $25, and $20, respectively. A local store places a daily order of 10 pounds of chocolate nuggets, which means that Francesco needs to make at least 10 pounds of the chocolate nuggets each day. Before sunrise each…arrow_forward

- allons of deionized water from each wholesaler to each distribution center is shown in the following table: Question Viewer a. Which of the following statements regarding setting up the tableau for the optimal solution for this problem is true? B. The sum of supply capacities is greater than the sum of demands, so a dummy distribution center is needed. C. The sum of supply capacities is less than the sum of demands, so a dummy wholesaler is needed. b. What is the total cost of the solution? The optimal cost is $ ((Enter your response rounded to the nearest dollar.)arrow_forwardJohn is travelling from home in Sydney to a hotel in Perth. Three stopovers on the way a number of choices of towns for each stop only one hotel to choose from in each town, except for Perth, where there are three hotels (J, K, and L) to choose from Each trip has a different distance resulting in a different cost (petrol) (cost is marked by each arc) Hotels have different costs (cost is marked by each node (town)) ● ● ● The goal is to select a route to and a hotel in Perth so that the overall cost of the trip is minimized. Use dynamic programming (forward recursion) to solve this problem by constructing the usual tables for each stage. Stage: 0 (Sydney) 1 Petrol cost start 22 8 12 Hotel cost 70 80 B 80 25 10 2 50 A E 70 30 10 18 8 7 3 50 F 70 70 H 60 8 10 10 4 (Perth) 50 13 K 10 15 L 60 70arrow_forwardThe manager of a company wishes to assign three jobs to four machines on one-on-one basis. The cost of each job on each machine if given on the following table. Solve it through Branch and Bound on Assignment Problem.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.