Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

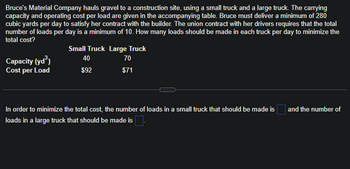

Transcribed Image Text:Bruce's Material Company hauls gravel to a construction site, using a small truck and a large truck. The carrying

capacity and operating cost per load are given in the accompanying table. Bruce must deliver a minimum of 280

cubic yards per day to satisfy her contract with the builder. The union contract with her drivers requires that the total

number of loads per day is a minimum of 10. How many loads should be made in each truck per day to minimize the

total cost?

Capacity (yd³)

Cost per Load

Small Truck Large Truck

40

70

$92

$71

In order to minimize the total cost, the number of loads in a small truck that should be made is and the number of

loads in a large truck that should be made is

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Similar questions

- Stooge Enterprises (Stooges) manufactures wooden mallets for commercial and residentialapplications. Stooges landed a major contract as a supplier to Slapsticks, Inc., a leading retailer inseveral major cities throughout the upper Midwest. Because of the large volume of demand,Stooges has to expand its manufacturing operation to three shifts and hire additional workers.Not long after Stooges began mallets to Slapsticks, it began receiving some complaints about mallethead diameters. This problem was somewhat alarming to Stooges, because its reputation as a highquality manufacturer was the principal reason that it was selected as a supplier to Slapsticks.Stooges placed a great deal of confidence in its manufacturing capability because of its well trainedand dedicated employees, and it never felt the need to consider formal process control approaches.In view of the recent complaints, the company president suspected that the expansion to a three-shift operation and the pressures to produce…arrow_forwardA wait and see capacity strategy minimizes the chances of lost sales due to insufficient capacity. true falsearrow_forwardA company operates 8 hours per shift, two shifts per day, five days a week with 12 hours maintenance per week and other downtime of 2 hours per week. What is the effective capacity in hours per week? Moving to thearrow_forward

- using spreadsheet models Using the Reciprocal Method allocate service centre costs Manufacturing $910,000 Assembly $175,000 Maintenance $472,000 Robotics $675,000 Department No. of Maintenance Jobs No. of Robotic Machines Manufacturing 265 16 Assembly 75 52 Maintenance 10 Robotics 28arrow_forwardd CE Additional Algo 5-11 Attrition Losses and Yields A process has three resources and two types of flows. The first flow has a demand of 20 units per day, and the second flow has a demand of 40 units per day. The first flow type visits all three resources, while the second flow type only visits the first and the third resources. The capacity is 100 units per day at the first resource, 40 units per day at the second resource, and 70 units per day at the third resource. 1. What is the demand total for each resource? Note: Do not round intermediate calculations. Resource Resource 1 Resource 2 Resource 3 Resource Resource 1 Resource 2 Resource 3 Type 1 20 20 20 Implied Utilization Actual Flow Rate 1 Actual Flow Rate 2 Type 2 2. What is the implied utilization for each resource? Note: Round your answers to 2 decimal places. 40 TO 40 Demand Total 3. What is the actual flow rate for each flow? Note: Round your answers to 2 decimal places.arrow_forwardT F Capacity is the degree to which input resourcesare physically changed by the conversion process.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.