Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

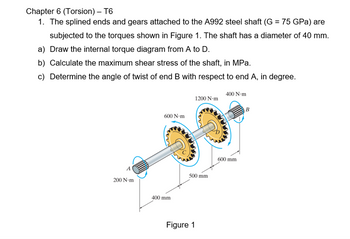

Transcribed Image Text:Chapter 6 (Torsion) - T6

1. The splined ends and gears attached to the A992 steel shaft (G = 75 GPa) are

subjected to the torques shown in Figure 1. The shaft has a diameter of 40 mm.

a) Draw the internal torque diagram from A to D.

b) Calculate the maximum shear stress of the shaft, in MPa.

c) Determine the angle of twist of end B with respect to end A, in degree.

200 N-m

600 N-m

400 mm

400 N-m

1200 N-m

500 mm

Figure 1

600 mm

B

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Similar questions

- The figure shows a rotating geared system. A torque of 3N is applied to an input gear in order to accelerate a flywheel at 0.1 rad/s2. The input gear has 11 teeth, and the output gear has 99 teeth. What is the flywheel's inertia? T=3N O O Input gear 11 teeth. Output gear 99 teeth 270 kgm² 57 kgm2 2.7 kgm2 Don't Know 27 kgm2 Flywheel 0.1 rad/s²arrow_forwardHomework helparrow_forwardMechanicsarrow_forward

- The two solid shafts are connected by the gears shown. The motor constantly supplies 20 kW of power at 15 Hz to system at A. The yield shear stress is 140 MPa for shaft (1) and 220 MPa for the shaft (2), and over all factor of safety is 2. a) Find the diameter of both shafts. b) If the modulus of rigidity of shaft (2) G is 77.2 GPa, calculate the relative angle of twist D with respect to C. 30 teeth B (1) 48 teeth Tp 0.8 marrow_forwardKindly write legibly. Thank you. Missing value is 170arrow_forwardPlease I want answer of that question from these choicesarrow_forward

- 400 mm Fr= 800 150mm C 600 N -Fa = 400 150mm Ft = Draw bending torsional moments, shear forces and normal force diagrams for the given gear shaft system.arrow_forwardParvinbhaiarrow_forwardThe shaft shown in the figure is machined from AISI 1040 CD steel. The shaft rotates at 1600 rpm and is supported in rolling bearings at A and B. The applied forces are F₁ = 1600 lbf and F2 = 640 lbf. A steady torque of 1600 lbf-in is being transmitted through the shaft between the points of application of the forces. 1 / in ] A in [lin -10 in- F₁ in F₂ -10 in- All fillets in R. 12in] 3 in The value of the notch sensitivity is The value of the fatigue stress concentration factor is in NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. What is the value of the theoretical stress concentration factor for torsion, the notch sensitivity, and the fatigue stress concentration factor? (You must provide an answer before moving to the next part.) The value of the theoretical stress concentration factor for torsion isarrow_forward

- pls expalin to me step by step and write clearly. i will rate your answer immediately thanksarrow_forwarda) Figure Q5 shows a 1.4 m long steel shaft that consists of a hollow segment AB and a solid segment BC. The shaft is fixed at C and is subjected to two external torques TA and TB at points A and B, respectively. The torque developed at the fixed end C is 750 kN.m in the direction as indicated in the figure. i) Determine the values of TA and TB if the corresponding angle of twist of end A is zero. ii) Calculate the maximum shear stress developed in the shaft. Give your comment whether the shaft will fail or not if the allowable shear stress of the shaft is 75 MPa. 750 kN.m 1.4 m 0.8 m C 160 mm B Тв 200 mm- ΤΑ Section a-a Figure Q5 = [Ans: a) i) T 332 kN.m, TB=1082 kN.m, ii) TCB,max = 60 MPa, TBA,max=45 MPa]arrow_forwardThe spur gear arrangement shown in the figure has a pinion (diver Gear A) that rotates at 625 rpm, an idler Gear B and a driven gear (Gear C). The gears have a module of 5 mm and a pressure angle of 20 degrees. Given the number of teeth as shown in the figure, determine: i) ii) iii) The pitch diameters of each of the gears. The torque that each shaft is required to transmit. The forces on each of the gears 40 teeth 490⁰ B 70 teeth 50 teetharrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY