Concept explainers

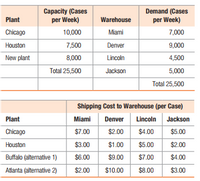

The Giant Farmer Company processes food for sale

in discount food stores. It has two plants: one in

Chicago and one in Houston. The company also oper-

ates warehouses in Miami, Florida; Denver, Colorado;

Lincoln, Nebraska; and Jackson, Mississippi. Forecasts

indicate that demand soon will exceed supply and that

a new plant with a capacity of 8,000 cases per week is

needed. The question is where to locate the new plant.

Two potential sites are Buffalo, New York, and Atlanta,

Georgia. The two tables at the bottom of this page give

data on capacities,

costs that have been gathered.

For each alternative new plant location, determine the ship-

ping pattern that will minimize total transportation costs.

Where should the new plant be located?

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

- Explain the a ssumptions behind the center-of-gravity method. How can the model be used in a service facility location?arrow_forwardWhat are the advantages and disadvantages of using the weighted factor method, centre of gravity method and location break even analysis in operations management when looking at locationsarrow_forwardb. An operations manager has narrowed down the search for a new King Kola plant to three locations. Fixed and variable costs follow. Location Fixed Cost Variable Cost A $100,000 $10 B $150,000 $7 C $200,000 $5 600 Annual 500 Cost ($000) 400 300 200 100 6 8 10 14 16 18 20 0 (000s of units) i. Plot the total cost curves in the chart provided above and identify the range over which each location would be best. ii. Use break-even analysis to calculate exactly the break-even quantity that defines each range.arrow_forward

- Discuss why quality of life issues should be considered in the facility location decisions ?arrow_forwardA manager has received an analysis of several cities being considered for a new officecomplex. The data (10 pts maximum) are as follows:Location AlternativesFactors A B CBusiness Service 7 6 6Community Services 5 6 7Real Estate Cost 5 8 7Construction Cost 6 7 6Cost of Living 2 7 8Taxes 6 5 4Transportation 7 7 8a. If the manager weights the factors equally, how would the locations stack up in terms of their composite factor rating scores?b. If business services and construction costs are given weights that are double the weights of the other factors, how would the locations stack uparrow_forwardOP i need all solution please help......arrow_forward

- Ching-Chang Kuo is considering opening a new foundryin Denton, Texas; Edwardsville, Illinois; or Fayetteville, Arkansas, to produce high-quality rifle sights. He has assem-bled the following fixed-cost and variable-cost data: PER-UNIT COSTS LOCATION FIXED COSTPER YEAR MATERIALVARIABLELABOR OVERHEADDenton $200,000 $ .20 $ .40 $ .40Edwardsville $180,000 $ .25 $ .75 $ .75Fayetteville $170,000 $1.00 $1.00 $1.00a) Graph the total cost lines.b) Over what range of annual volume is each facility goingto have a competitive advantage?c) What is the volume at the intersection of the Edwardsvilleand Fayetteville cost lines?arrow_forwardA producer of pottery is considering the addition of a new plant to absorb the backlog of demand that now exists. The primary location being considered will have the following cost structures as shown in the table. The producer knows there is a big order or order contract that will be awarded by the giant retail WalWal. The producer is not certain as what capacity production is to produce. It all depends on WalWal’s contract. The producer has also been informed, the first batch of pottery is required to ship in a very tight time frame from the first production run. The producer decides to plan ahead and select the best production process to set up for manufacturing. Process 1 Process 2 Process 3 Ann. Fixed Cost $ 7,017 9,035 14,251 variable cost $/unit 1.05 0.78 0.63 The producer wants you to help them to identify at what range of production quantity (Q) for Process 1, Process 2, and Process 3 is best to adopt.Enter Q range with whole number and use…arrow_forwardA producer of pottery is considering the addition of a new plant to absorb the backlog of demand that now exists. The primary location being considered will have fixed costs of $11,152 per month and variable costs of $1.23 per unit produced. Each item is sold to retailers at a price that averages $2.07 a) The volume per month is required in order to break even = Blank 1 (in whole number) b) The profit or loss would be realized on a monthly volume of 61,000 units Blank 2 c) The volume is needed to obtain a profit of $16,000 per month = Blank 3 (in whole number) d) The volume is needed to provide revenue of $23,000 per month = Blank 4 (in whole number)arrow_forward

- (use excel to show formulas used) Amazing is evaluating three locations for a second headquarters. Costs for construction at location A are $18,900,000, Location B are $21,700,000 and Location C are $23,300,000. Variable costs for Location A are $16, Location B are $14 and Location C are $12. The company plans to sell products for $27. What is the break-even point for each location?arrow_forwardDecision factors Amazon might consider before choosing a city to locate their new Headquarters - Please explain each factor in detail. Cost-Effective land Skilful labours residing nearby to Headquarters. Potential for growth Demographic Accessibility and Parking Proximity to other businesses and services Building's infrastructure Competitionarrow_forwardWhen placing a new medical clinic, the county healthcommissioner, Vicky Luo, wishes to consider three sites. Thepertinent da ta a re given in the fo llowing table. Which is thebest site (assuming a higher weight is more desirable than alower one)?arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.