Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

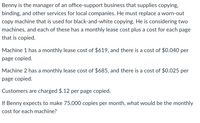

Transcribed Image Text:Benny is the manager of an office-support business that supplies copying,

binding, and other services for local companies. He must replace a worn-out

copy machine that is used for black-and-white copying. He is considering two

machines, and each of these has a monthly lease cost plus a cost for each page

that is copied.

Machine 1 has a monthly lease cost of $619, and there is a cost of $0.040 per

page copied.

Machine 2 has a monthly lease cost of $685, and there is a cost of $0.025 per

page copied.

Customers are charged $.12 per page copied.

If Benny expects to make 75,000 copies per month, what would be the monthly

cost for each machine?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- A steel production plant manufactures bands and coils which sell at a profit of $25 and $30 per ton,respectively. The production rate of the plant for bands is 200 tons/hr, and that for coils is 140 tons/hr.Based on the market analysis, it has been identified that the weekly demand is at most 6000 tons and4000 tons for bands and coils, respectively . The plant operates for a maximum of 40 hours per week. 1. In Microsoft Excel, formulate a linear programming model instance for this problem, then solve. 2. Assume that the products need to be painted after manufacturing, and the painting departmentcan paint at a rate of 600 tons per hour for bands and 400 tons per hour for coils. The paintingdepartment works only for 20 hours. Update the linear programming model instance to accom-modate this requirement, and re-solve the problem. 3. The plant is planning to introduce another product “rods” to its production mix with the followingparameters:•Profit/ton = $40•Production volume = 150…arrow_forwardCharles Lackey operates a bakery in Idaho Falls, Idaho. Because of its excellent product and excellent location, demand has increased by 45% in the last year. On far too many occasions, customers have not been able to purchase the bread of their choice. Because of the size of the store, no new ovens can be added. At a staff meeting, one employee suggested ways to load the ovens differently so that more loaves of bread can be baked at one time. This new process will require that the ovens be loaded by hand, requiring additional manpower. This is the only production change that will be made in order to meet the increased demand. The bakery currently makes 1,500 loaves per month. Employees are paid $8 per hour. In addition to the labor cost, Charles also has a constant utility cost per month of $550 and a per loaf ingredient cost of $0.40. Current multifactor productivity for 640 work hours per month = loaves/dollar (round your response to three decimal places).arrow_forwardMultiple Choice: If the bakery had to produce at least one chocolate cake for every four apple pies, which of the following constraints represents better such a condition? Here: C is chocolate cakes, and A is apple pies. C+A <= 4 C+A >= 4 4C >= A None C >= 4Aarrow_forward

- . An airline company must plan its fleet capacity and its long-term schedule of aircraft usage. For one flight segment, the average number of customers per day is 70, which represents a 65 percent utilization rate of the equipment assigned to the flight segment. If demand is expected to increase to 84 customers for this flight segment in 3 years, what capacity requirement should be planned? Assume that management deems that a capacity cushion of 25 percent is appropriate.arrow_forwardSolve the question below using the attached excel templates with formulas for renting both slow and fast copies (labeled in the excel tabs). Question: The Decision Sciences Department is trying to determine whether to rent a slow or a fast copier. The department believes that an employee’s time is worth $15 per hour. The slow copier rents for $4 per hour, and it takes an employee an average of 10 minutes to complete copying. The fast copier rents for $15 per hour, and it takes an employee an average of six minutes to complete copying. On average, four employees per hour need to use the copying machine. (Assume the copying times and interarrival times to the copying machine are exponentially distributed.) Which machine should the department rent to minimize expected total cost per hour?arrow_forwardThe manager of a car wash must decide whether to have one or two wash lines. One line will mean a fixed cost of $6,000 a month, and two lines will mean a fixed cost of $10,500 a month. Each line would be able to process 15 cars an hour. Variable costs will be $3 per car, and revenue will be $5.95 per car. The manager projects an average demand of between 14 and 18 cars anhour. Would you recommend one or two lines? The car wash is open 300 hours a month.arrow_forward

- 14arrow_forwardA Company Is Considering Buying One Of The Following Two Machines. Show the complete solution for each question.arrow_forwardMcDonalds has a drive-through window and, during peak lunch times, can handle a maximum of 85 cars per hour with one person taking orders, assembling them, and acting as cashier. The average sale per order is $12.00. A proposal has been made to add two additional workers and divide the tasks among the three. One will take orders, the second will assemble them, and the third will act as a cashier. With this system, it is estimated that 120 cars per hour can be serviced. Use productivity arguments to recommend whether or not to change the current system. Hint: Productivity = revenue/labor dollararrow_forward

- Create a Crow’s Foot notation ERD to support the following business operations: Create a Crowsfoot notation ERD to support the following business operations: - A friend of yours has opened Marshfield Electronics and Repairs (MER) to repair smartphones, laptops, tablets, and MP3 players. She wants you to create a database to help her run her business. When a customer brings a device to MER for repair, data must be recorded about the customer, the device, and the repair (also referred to as repair request). Completing each repair request can involve multiple services (e.g. glass replacement, battery replacement, cleaning. Some services require parts. The customer’s name, address, and a contact phone number must be recorded. For the device to be repaired, the type of device, model, and serial number are recorded (or verified if the device is already in the system). Each repair request is given a reference number, which is recorded in the system along with the date of the request, and a…arrow_forwardThe city of Winnipeg is considering whether to build a new public ice rink. This rink would have a capacity of 800 ice skaters per day, and the proposed admission fee is $6 per individual per day. The estimated cost of the ice rink, averaged over the life of the rink, is $4 per ice skater per day. The city of Winnipeg has hired you to assess this project. Fortunately, Ottawa already has an ice rink, and the city of Ottawa has randomly varied the price of that rink to find how price affects usage. The results from their study follow: Ice rink price Number of ice skaters per day $8 $10 $4 $6 $2 per day 500 200 1100 800 1400 a. If the ice rink is built as planned, what would be the net benefit per day from the ice rink? What is the consumer surplus for ice skaters? b. Given this information, is an 800-ice rink the optimally sized ice rink for Winnipeg to build? Explain.arrow_forwardSolve the question below using the attached excel templates with formulas for renting both slow and fast copies (labeled in the excel tabs). Question: The Decision Sciences Department is trying to determine whether to rent a slow or a fast copier. The department believes that an employee’s time is worth $15 per hour. The slow copier rents for $4 per hour, and it takes an employee an average of 10 minutes to complete copying. The fast copier rents for $15 per hour, and it takes an employee an average of six minutes to complete copying. On average, four employees per hour need to use the copying machine. (Assume the copying times and interarrival times to the copying machine are exponentially distributed.) Which machine should the department rent to minimize expected total cost per hour?arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.