Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

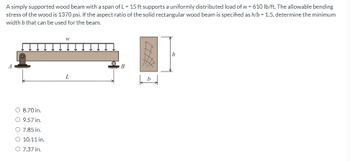

Transcribed Image Text:A simply supported wood beam with a span of L = 15 ft supports a uniformly distributed load of w = 610 lb/ft. The allowable bending

stress of the wood is 1370 psi. If the aspect ratio of the solid rectangular wood beam is specified as h/b = 1.5, determine the minimum

width b that can be used for the beam.

O 8.70 in.

O 9.57 in.

O 7.85 in.

O 10.11 in.

O 7.37 in.

W

L

B

b

h

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 9 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- M = 2. A beam of length 10 m and of uniform rectangular section is supported at its ends and carries uniformly distributed load over the entire length. Calculate the depth of the section if the maximum permissible bending stress is 16 N/mm² and central deflection is not to exceed 10 mm. Take the value of E = 1.2 × 104 N/mm². Use the following g equations: w.L² 8 ус W.L 161 8 d = 2 W.L 8 == WL³ 5 384 ΕΙ (: W = w.L)arrow_forwardDetermine the minimum depth, h, of the beam to the nearest 4 kip/ft 1/8" that will safely support the loading shown. The allowable bending stress is oallow = 21 ksi and the allowable shear stress is 12 ft 6 ft = 10 ksi. The beam has a Tallow uniform thickness of 3".arrow_forwardA simply supported wood beam with a span of L = 14 ft supports a uniformly distributed load w. The beam width is b = 7 in. and the beam height is h = 14 in. The allowable bending stress of the wood is 810 psi. Determine the magnitude of the maximum load w that may be carried by the beam. Answer: w = Mi lb/ft.arrow_forward

- A simply supported wood beam with a span of L-9 ft supports a uniformly distributed load w. The beam width is b-5 in, and the beam height is h=9 in. The allowable bending stress of the wood is 980 psi. Determine the magnitude of the maximum load w that may be carried by the beam. Answer: W- i| 1 lb/ft.arrow_forwardA beam fabricated from western white pine has been reinforced by bonding steel strips on its top and bottom 1.5 ksi in the surfaces as shown. If the design is limited to wood = 1.5 ksi in the wood and a steel wood and steel = 35.6 ksi in the steel, determine the maximum bending moment if the beam bends about its vertical axis of symmetry. L3 Given: • L₁= 10 in • L₂ L₂ = 0.9 in • L3= 5.3 in Mmar SEHERAPECES SANTREMANEN La prender PERANAN PE P number (rtol-0.01, atol=1e-05) STEEL E WOOD N.A. L₁ kip. in L₂ L₂ Phuarrow_forwardI want the correct answers pleasearrow_forward

- Pls help ASAParrow_forwardDetermine from the beam and the loads shown: Reactions on supports Shear force diagram Bending moment diagram The neutral axis The moment of inertia The first moment of area Consider a section located 1100 mm from point A. Determine: The maximum normal stress of the section The maximum shear stress of the section Deflection The slopearrow_forwardA beam fabricated from western white pine has been reinforced by bonding steel strips on its top and bottom surfaces as shown. If the design is limited to a wood 1 ksi in the wood and steel = 34.4 ksi in the steel, determine the maximum bending moment if the beam bends about its horizontal axis of symmetry. Given: • L₁ = 11.2 in • L₂ = 1.7 in • L3 = 4.3 in Mmar STEEL N.A. Pa WOOD number (rtol=0.01, atol=1e-05) 1 -L3 1 1 1 1 1 1 L₂ L₁ L2 kip. in earrow_forward

- Determine the maximum bending stress (in psi) in the beam and its location as generated from the loading condition with the beam cross-section shown below. 2 kip/ft -5 ft- -5 ft 30 kip-ft -5 ft- B 12"- 6" AXarrow_forwardDetermine the maximum bending moment magnitude for the beam shown below. Use a = 16 ft, b = 6 ft, and w = 10 kips/ft. The reaction forces for this beam are Ay = 68.7 kips and By = 151.2 kips. B |C a b. Answer: Mmax = i kip-ftarrow_forwardThe T-beam is made from two plates welded together as shown. Determine the maximum uniform distributed load w that can be safely supported on the beam if the allowable bending stress is allow = 159 MPa and the allowable average shear stress is Tallow = 71 MPa. [w = 11.4 kN/m] A -1.5 m -1.5 m- 200 mm T 20 mm 200 mm 20 mmarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY