Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

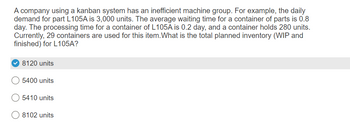

Transcribed Image Text:A company using a kanban system has an inefficient machine group. For example, the daily

demand for part L105A is 3,000 units. The average waiting time for a container of parts is 0.8

day. The processing time for a container of L105A is 0.2 day, and a container holds 280 units.

Currently, 29 containers are used for this item.What is the total planned inventory (WIP and

finished) for L105A?

8120 units

5400 units

5410 units

8102 units

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps

Knowledge Booster

Similar questions

- true or false- Five different products on a pallet being moved, is equal to one unit load.arrow_forwardUsage at a work center is 300 parts per day, and a standard container holds 25 parts. It takesan average of .12 day for a container to complete a circuit from the time a kanban card isreceived until the container is returned empty. Compute the number of kanban cards (containers) needed if X = .20.arrow_forwardMarkland First National Bank of Rolla utilizes kanban techniques in its check processing facility. The following information is known about the process. Each kanban container can hold 25 checks and spends 24 minutes a day in processing and 2 hours a day in materials handling and waiting. Finally, the facility operates 24 hours per day and utilizes a policy variable for unforeseen contingencies of 0.20. a. If there are 29 kanban containers in use, the current daily demand of the check processing facility is units. (Enter your response rounded to the nearest whole number.)arrow_forward

- A company using a kanban system has an inefficient machine group. For example, the daily demand for part L105A is 3,000 units. The average waiting time for a container of parts is 0.8 day. The processing time for a container of L105A is 0.2 day, and a container holds 270 units. Currently, 20 containers are used for this item.a. What is the value of the policy variable, a?b. What is the total planned inventory (work-in-process and finished goods) for item L105A?c. Suppose that the policy variable, a, was 0. How many containers would be needed now? What is the effect of the policy variable in this example?arrow_forwardWork-in-process inventory is devoted to maintenance, repair, and operating materials. A True B Falsearrow_forwardIn which ways, if any, are the following systems analogous to kanban: returning empty bottles to the supermarket and picking up filled ones; running a hot dog stand at lunchtime; withdrawing money from a checking account; raking leaves into bags?arrow_forward

- Please do not give solution in image format thanku response asaparrow_forward29 Meritor is so pleased with the outcome from previous suggestions that the consultants are invited back for more work. The consultants now suggest a more complete robotic automation of the making of muffler assemblies and also a reduction in container size to five per container. Meritor implements these suggestions and the result is that the muffler assembly fabrication cell now averages approximately 20 assemblies per hour, and the catalytic converter assembly cell can now respond to an order for a batch of catalytic converters in one hour. The safety stock remains at 11.5 percent. How many kanban cards are needed? Note: Round up your answer to the next whole number.arrow_forwardCompute Lead Time Jackson Fabricators Inc. machines metal parts for the automotive industry. Under the traditional manufacturing approach, the parts are machined through two processes: milling and finishing. Parts are produced in batch sizes of 80 parts. A part requires 2 minutes in milling and 6 minutes in finishing. The move time between the two operations for a complete batch is 7 minutes. Under the lean philosophy, the part is produced in a cell that includes both the milling and finishing operations. The operating time is unchanged; however, the batch size is reduced to 5 parts and the move time is eliminated. Determine the value-added, non-value-added, and total lead times, and the value-added ratio under the traditional and lean manufacturing methods. If reguired, round percentages to one decimal place. Traditional Philosophy Lean Manufacturing Philosophy Value-added time 8 V min 8 V min Non-value-added time 632 X min 48 x min Total lead time 640 x min 56 x min Value-added ratio…arrow_forward

- The White Tooth Device Company is a manufacturer of high-end electric toothbrushes. For each toothbrush, there is a sequence of assembly steps performed by five workers. Each worker does two tasks. Inventory buffers are allowed between workers. (a) What is the capacity and cycle time of this process? (b) What is the idle time of each worker if the process operates at full capacity? (c) Suppose two workers could be hired, F and G, and they take the same time to complete tasks as the current five workers. F and G can be assigned to work on the same pair of tasks as one of the current workers. For example, F could be assigned tasks T1 and T2 (just like worker A) while G is assigned T5 and T6 (just like worker C). They cannot be assigned tasks that are currently assigned to two workers. For example, F cannot be assigned to tasks T2 and T3 (because they are currently being done by workers A and B). What is the capacity of this process with workers F and G included?arrow_forwardMarkland First National Bank of Rolla utilizes kanban techniques in its check processing facility. The following information is known about the process. Each kanban container can hold 25 checks and spends 24 minutes a day in processing and 2 hours a day in materials handling and waiting. Finally, the facility operates 24 hours per day and utilizes a policy variable for unforeseen contingencies of 0.20. a. If there are 29 kanban containers in use, the current daily demand of the check processing facility is 6,000 units. (Enter your response rounded to the nearest whole number.) b. If the muda or the waste in the system were eliminated completely, whole number.) containers would then be needed. (Enter your response rounded up to the nextarrow_forwardA Printed Circuit Board (PCB) machine installs integrated circuits onto a board. Before starting to produce a board, the PCB machine requires a 20-minute setup. Once in production, the PCB machine requires only 0.15 minute per board. Assume there is ample demand. Currently, the PCB machine produces 500 boards between setups. Given this operating process, what is the capacity of the PCB machine (in boards per minutes)? answer:_________boards per minutearrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.