Cornerstones of Cost Management (Cornerstones Series)

4th Edition

ISBN: 9781305970663

Author: Don R. Hansen, Maryanne M. Mowen

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Question

Right Answer

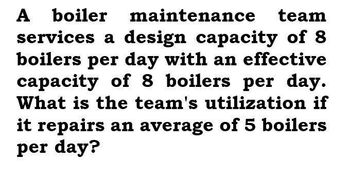

Transcribed Image Text:A boiler

maintenance

team

services a design capacity of 8

boilers per day with an effective

capacity of 8 boilers per day.

What is the team's utilization if

it repairs an average of 5 boilers

per day?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- A boiler maintenance team services a design capacity of 8 boilers per day with an effective capacity of 8 boilers per day. What is the team's utilization if it repairs an average of 5 boilers per day?solve this problemarrow_forwardSolve this Accounting problemarrow_forwardA manual assembly line is being designed for a product with annual demand = 100,000 units. The line will operate 50 wks/year, 5 shifts/wk, and 7.5 hr/shift. Work units will be attached to a continuously moving conveyor. Work content time = 42.0 min. Assume line efficiency E = 0.97, balancing efficiency Eb = 0.92, and repositioning time Tr = 6 sec. Determine: (a) hourly production rate to meet demand, (b) number of workers required.arrow_forward

- Assume that the inspection activity has an expected cost of 120,000. Expected direct labor hours are 3,000, and expected number of inspections is 600. The best activity rate for inspection is as follows: a. 40 per inspection b. 40 per hour c. 200 per inspection d. 200 per hourarrow_forwardThe management of Hartman Company is trying to determine the amount of each of two products to produce over the coming planning period. The following information concerns labor availability, labor utilization, and product profitability: Labor-Hours Required(hours/unit) Department Product 1 Product 2 Hours Available A 1.00 0.35 95 B 0.30 0.20 36 C 0.20 0.50 50 Profit contribution/unit $30.00 $15.00 (a) Develop a linear programming model of the Hartman Company problem. Solve the model to determine the optimal production quantities of products 1 and 2. If required, round your answer to two decimal places. Product 1 Product 2 Production (b) In computing the profit contribution per unit, management does not deduct labor costs because they are considered fixed for the upcoming planning period. However, suppose that overtime can be scheduled in some of the departments. Which departments would you recommend scheduling for…arrow_forwardJoey is trying hard to make a sale and is happy to help you gather info on the MD64s. After a long phone chat, you have the following information. MD64 Purchase Price $ 750,000 Annual Utilization (hrs/yr) 2,000 Expected Life (yrs) 7 Salvage Value 24 200,000 Annual Cost Fuel, Oil, Grease, etc. 75,000 Lifetime Cost of Repairs $ 750,000 Capacity (tons) 64 Cycle Time (min) 12 The quarry as a whole works 50 mins of each hour. Calculate the hourly rates for the MD64 haulers, the production rate, and the unit cost each can achieve. MD64arrow_forward

- Labor cost for set-up is $500/hour. The plant plans on level material use and operates 50 days per year to satisfy an annual demand of 5000 units. Dailty production is projected to be 1000 units and lot size is 700. Annual holding cost per unit is projected to be $25. Calculate the time it takes to setup.arrow_forwardNash Corporation manufactures and sells custom snowmobiles. From the time an order is placed till the time the snowmobile reaches the customer averages 50 days. This 50 days is spent as follows: Wait time: 10 days Move time: 5 days Process time: 15 days Queue time: 15 days Inspection time: 5 days What is Nash's manufacturing cycle efficiency (MCE) for its snowmobiles?arrow_forwardA manager must decide which type of machine to buy, A, B, or C. Machine costs (per individual machine) are as follows: Machine Cost A $ 60,000 B $ 50,000 C $ 60,000 Product forecasts and processing times on the machines are as follows: PROCCESSING TIME PER UNIT (minutes) Product AnnualDemand A B C 1 16,000 3 4 4 2 10,000 6 5 1 3 15,000 1 3 6 4 17,000 5 3 4 a. Assume that only purchasing costs are being considered. Compute the total processing time required for each machine type to meet demand, how many of each machine type would be needed, and the resulting total purchasing cost for each machine type. The machines will operate 10 hours a day, 240 days a year. (Enter total processing times as whole numbers. Round up machine quantities to the next higher whole number. Compute total purchasing costs using these rounded machine quantities. Enter the resulting total purchasing cost as a whole number. Omit the "$" sign.) Total…arrow_forward

- Your plant produces 134 snowmobiles per month. Direct costs are $2,540 per snowmobile. The monthly overhead is $87,000. What is the average cost per snowmobile with overhead? Solve the problemarrow_forwardCrystal Pools estimates overhead will utilize 250,000 machine hours and cost $750,000. It takes 2 machine hours per unit, direct material cost of $14 per unit, and direct labor of $20 per unit. What is the cost of each unit produced?arrow_forwardA process costs $200 to set up. The run time is 5 minutes per piece and the run costis $30 per hour. Determine the following:a. The fixed cost.b. The variable cost.c. The total cost and unit cost for a lot of 600.d. The total cost and unit cost for a lot of 1200.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning Excel Applications for Accounting PrinciplesAccountingISBN:9781111581565Author:Gaylord N. SmithPublisher:Cengage LearningPrinciples of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College

Excel Applications for Accounting PrinciplesAccountingISBN:9781111581565Author:Gaylord N. SmithPublisher:Cengage LearningPrinciples of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning Principles of Cost AccountingAccountingISBN:9781305087408Author:Edward J. Vanderbeck, Maria R. MitchellPublisher:Cengage Learning

Principles of Cost AccountingAccountingISBN:9781305087408Author:Edward J. Vanderbeck, Maria R. MitchellPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...

Accounting

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Cengage Learning

Excel Applications for Accounting Principles

Accounting

ISBN:9781111581565

Author:Gaylord N. Smith

Publisher:Cengage Learning

Principles of Accounting Volume 2

Accounting

ISBN:9781947172609

Author:OpenStax

Publisher:OpenStax College

Managerial Accounting: The Cornerstone of Busines...

Accounting

ISBN:9781337115773

Author:Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:Cengage Learning

Principles of Cost Accounting

Accounting

ISBN:9781305087408

Author:Edward J. Vanderbeck, Maria R. Mitchell

Publisher:Cengage Learning