Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

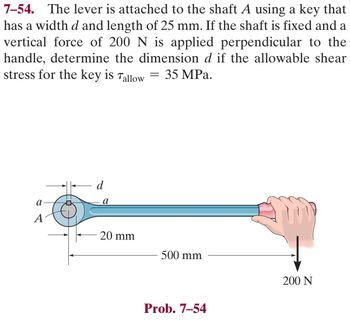

Transcribed Image Text:7-54. The lever is attached to the shaft A using a key that

has a width d and length of 25 mm. If the shaft is fixed and a

vertical force of 200 N is applied perpendicular to the

handle, determine the dimension d if the allowable shear

stress for the key is Tallow

35 MPa.

a

A

d

a

20 mm

=

500 mm

Prob. 7-54

200 N

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 14 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- 7-54. The lever is attached to the shaft A using a key that has a width d and length of 25 mm. If the shaft is fixed and a vertical force of 200 N is applied perpendicular to the handle, determine the dimension d if the allowable shear stress for the key is Talloe - 35 MPa. -20 mm 500 mm 200 Narrow_forwardThe bar is connected to the support using a pin having a diameter of d = 1 in. If the allowable tensile stress for the bar is 1st2allow = 20 ksi, and the allowable bearing stress between the pin and the bar is 1sb2allow = 30 ksi,determine the dimensions w and t so that the gross area of the cross-section is wt = 2 in2 and the load P is a maximum. What is this maximum load? Assume the hole in the bar has the same diameter as the pin.arrow_forward300 Ib/ft 3. Six nails are used to hold the hanger at A against the column. Determine the minimum required diameter of each nail to the nearest 1/16 in. if it is made of material having 7fail = 16 ksi. Apply a factor of safety of F.S. = 2 against shear failure. B -9 ftarrow_forward

- how do we know these values if they're not givenarrow_forward7-70. The assembly consists of three disks A, B. and C that are used to support the load of 140 kN. Determine the smallest diameter d, of the top disk, the diameter d, within the support space, and the diameter d, of the hole in the bottom disk. The allowable bearing stress for the material is (o.)al - 125 MPa. 350 MPa and allowable shear stress is Tali - 140 kN 20 mmarrow_forward7-70. The assembly consists of three disks A, B, and C that are used to support the load of 140 kN. Determine the smallest diameter di of the top disk, the diameter dy within the support space, and the diameter dy of the hole in the bottom disk. The allowable bearing stress for the material is (a.)ler - 350 MPa and allowable shear stress is Tlon - 125 MPa. 140 kN d. 20 mm 10 mmarrow_forward

- The shaft is supported by a thrust bearing at A and a journal bearing at B. If P = 20 kN, determine the absolute maximum shear stress in the shaft.arrow_forward7-70. The assembly consists of three disks A, B, and C that are used to support the load of 140 kN. Determine the smallest diameter di of the top disk, the diameter dz within the support space, and the diameter dy of the hole in the bottom disk. The allowable bearing stress for the material is (7,)alow - 350 MPa and allowable shear stress is Tlon - 125 MPa. 140 kN 20 mm 10 mmarrow_forward1-35. If the turnbuckle is subjected to an axial force of P=900 lb, determine the average normal stress developed in section a-a and in each of the bolt shanks at B and C. Each bolt shank has a diameter of 0.5 in. B N -1 in.- 0.25 in.arrow_forward

- *RI4-8. A strain gauge forms an angle of 45° with the axis of the 50-mm diameter shaft. If it gives a reading of e - -200(10-6) when the torque T is applied to the shaft, determine the magnitude of T. The shaft is made from A-36 steel.arrow_forwardThe aluminum tube is subjected to a torque of M = 2 kN m. Determine the average shear stress in the tube if the dimension a = 200 mm. Each side has a thickness oft = 6 mm. Give the answer in the box in MPa with one decimal place. (ANSWER NEATLY AND ASAP ONLY IF CORRECT)arrow_forward7-63. The cotter is used to hold the two rods together. Determine the smallest thickness t of the cotter and the smallest diameter d of the rods. All parts are made of steel for which the failure normal stress is fail 500 MPa and the failure shear stress is fail 375 MPa. Use a factor of safety of (F.S.), = 2.50 in tension and (F.S.), = 1.75 in shear. -d- 30 kN 40 mm d - 30 kN t Prob. 7-63 10 mm =arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY