Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

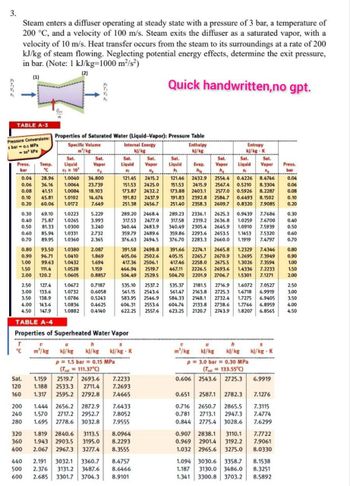

Transcribed Image Text:3.

Steam enters a diffuser operating at steady state with a pressure of 3 bar, a temperature of

200 °C, and a velocity of 100 m/s. Steam exits the diffuser as a saturated vapor, with a

velocity of 10 m/s. Heat transfer occurs from the steam to its surroundings at a rate of 200

kJ/kg of steam flowing. Neglecting potential energy effects, determine the exit pressure,

in bar. (Note: 1 kJ/kg-1000 m²/s²)

(1)

(2)

Quick handwritten,no gpt.

TABLE A-3

Qe

Pressure Conversions: Properties of Saturated Water (Liquid-Vapor): Pressure Table

1 bar -0.1 MPa

Specific Volume

m/kg

Internal Energy

10 kPa

kj/kg

Enthalpy

kj/kg

Entropy

kj/kg K

Sat.

Sat.

Sat.

Press.

bar

0.04 28.96

0.06 36.16

Temp.

"C

Liquid

Vapor

Liquid

Sat.

Vapor

Sat.

By x10

Evap. Vapor

he

1.0040 34.800

1.0064 23.739

0.08 41.51

1.0084 18.103

0.10

45.81

1.0102

14.674

0.20

60.06

1.0172

7.649

121.45 2415.2

151.53 2425.0

173.87 2432.2

191.82 2437.9

251.38 2456.7

Sat.

Liquid

hi

his

121.46 2432.9 2554.4 0.4226 8.4746

151.53 2415.9 2567.4 0.5210 8.3304

173.88 2403.1 2577.0 0.5926 8.2287

191.83 2392.8 2584.7 0.6493 8.1502

251.40 2358.3 2609.7 0.8320 7.9085

Sat.

Liquid

St

Sat.

Vapor

Press.

bar

0.04

0.06

0.08

0.10

0.20

0.30

69.10

1.0223

5.229

0.40

75.87

1.0265

3.993

0.50

81.33

1.0300

3.240

0.60 85.94

1.0331

2.732

0.70

89.95

1.0360

2.365

289.20 2468.4

317.53 2477.0

340.44 2483.9

359.79 2489.6

376.63 2494.5

289.23

2336.1

317.58 2319.2

340.49 2305.4

359.86 2293.6

376.70 2283.3

2625.3 0.9439

7.7686

0.30

2636.8 1.0259 7.6700

2645.9 1.0910 7.5939

2653.5 1.1453 7.5320

2660.0 1.1919 7.4797

0.40

0.50

0.60

0.70

0.80

93.50

1.0380

2.087

391.58 2498.8

0.90

96.71

1.0410

1.869

405.06 2502.6

1.00

99.63

1.0432

1.694

417.36 2506.1

1.50

111.4

1.0528

1.159

466.94 2519.7

2.00

120.2

1.0605

0.8857

2.50 127.4

1.0672

3.00 133.6

1.0732

0.7187

0.6058

3.50 138.9

1.0786

0.5243

4.00 143.6

1.0836

0.4625

4.50 147.9

1.0882 0.4140

504.49 2529.5

535.10 2537.2 535.37 2181.5 2716.9 1.6072 7.0527

561.15 2543.6 561.47 2163.8 2725.3 1.6718 6.9919

583.95 2546.9 584.33 2148.1 2732.4 1.7275 6.9405

604.31 2553.6 604.74 2133.8 2738.6 1.7766 6.8959

622.25 2557.6 623.25 2120.7 2743.9 1.8207 6.8565

391.66 2274.1 2665.8 1.2329

405.15 2265.7 2670.9 1.2695 7.3949

417.46 2258.0 2675.5 1.3026 7.3594

467.11 2226.5 2693.6 1.4336 7.2233

504.70 2201.9 2706.7 1.5301 7.1271

7.4346

0.80

0.90

1.00

1.50

2.00

2.50

3.00

3.50

4.00

4.50

TABLE A-4

Properties of Superheated Water Vapor

T

°C

m³/kg

kJ/kg

h

kJ/kg

kJ/kg - K

m³/kg

kJ/kg

h

kj/kg

kj/kg K

p = 1.5 bar =0.15 MPa

Sat.

1.159

(Tsat = 111.37°C)

2519.7 2693.6

7.2233

p = 3.0 bar = 0.30 MPa

(Tsat = 133.55°C)

0.606 2543.6 2725.3

6.9919

120

160

1.188 2533.3 2711.4

1.317 2595.2 2792.8

7.2693

7.4665

200

1.444 2656.2 2872.9

7.6433

0.651 2587.1 2782.3 7.1276

0.716

240 1.570 2717.2 2952.7

280 1.695 2778.6 3032.8

7.8052

7.9555

2650.7 2865.5 7.3115

0.781 2713.1 2947.3 7.4774

0.844 2775.4 3028.6

7.6299

320

360

1.819 2840.6 3113.5

1.943 2903.5 3195.0

400 2.067 2967.3 3277.4

8.0964

8.2293

8.3555

0.907 2838.1 3110.1

0.969 2901.4 3192.2

1.032 2965.6 3275.0

7.7722

7.9061

8.0330

440 2.191 3032.1 3360.7 8.4757

500 2.376 3131.2 3487.6

600 2.685 3301.7 3704.3

8.6466

1.187

8.9101

1.341

1.094 3030.6 3358.7 8.1538

3130.0 3486.0 8.3251

3300.8 3703.2 8.5892

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Similar questions

- T-3arrow_forwardSteam enters a turbine operating at steady state at 800°F and 450 Ibf/in2 and leaves as a saturated vapor at 0.8 Ibf/in2. The turbine develops 12,000 hp, and heat transfer from the turbine to the surroundings occurs at a rate of 2 x 106 Btu/h. Neglect kinetic and potential energy changes from inlet to exit. Determine the exit temperature, in °F, and the volumetric flow rate of the steam at the inlet, in ft³/s.arrow_forwardSteam enters a turbine operating at steady state at 440°C and 30 bar and leaves as a saturated vapor at 0.08 bar. The turbine develops 9000 kW, and heat transfer from the turbine to the surroundings occurs at a rate of 590 kW. Neglect kinetic and potential energy changes from inlet to exit. a. Determine the exit temperature, in °C. b. Determine the volumetric flow rate of the steam at the inlet, in m³/s. T₁-440°C P₁=30 bar Qout 590 kW 2 X₂ 100%(sat.vapor) P₂=0.08 bar W turbine = 9000 kWarrow_forward

- Steam enters a turbine operating at steady state at 850°F and 450 Ibf/in? and leaves as a saturated vapor at 1.0 lbf/in?. The turbine develops 12,000 hp, and heat transfer from the turbine to the surroundings occurs at a rate of 2x 106 Btu/h. Neglect kinetic and potential energy changes from inlet to exit. Determine the exit temperature, in °F, and the volumetric flow rate of the steam at the inlet, in ft/s. Step 1 Determine the exit temperature, in °F. T2 = °F.arrow_forwardSteam enters a turbine operating at steady state at 750°F and 450 lbf/in² and leaves as a saturated vapor at 0.8 lbf/in². The turbine develops 12,000 hp, and heat transfer from the turbine to the surroundings occurs at a rate of 2 x 106 Btu/h. Neglect kinetic and potential energy changes from inlet to exit. Determine the exit temperature, in °F, and the volumetric flow rate of the steam at the inlet, in ft3/s. Step 1 Your answer is correct. Determine the exit temperature, in °F. T2 = 94.3 Hint Step 2 °F. Determine the volumetric flow rate of the steam at the inlet, in ft³/s. (AV) 1 = i ft³/s Attempts: 1 of 4 usedarrow_forwardRefrigerant 134a enters an insulated diffuser as a saturated vapor at 120°F with a velocity of 1200 ft/s. The inlet area is 1.4 in?. At the exit, the pressure is 400 Ibf/in? and the velocity is negligible. The diffuser operates at steady state and potential energy effects can be neglected. Determine the mass flow rate, in Ib/s, and the exit temperature, in °F.arrow_forward

- Refrigerant 134a enters an insulated diffuser as a saturated vapor at 80°F with a velocity of 1400 ft/s. The inlet area is 1.4 in². At the exit, the pressure is 400 lb/in² and the velocity is negligible. The diffuser operates at steady state and potential energy effects can be neglected. Determine the mass flow rate, in lb/s, and the exit temperature, in °F. Step 1 Determine the mass flow rate, in lb/s. Your answer is correct. m = 28.887 Hint Step 2 lb/s. * Your answer is incorrect. Determine the exit temperature, in °F. T₂=276.41 °F Attempts: 1 of 4 usedarrow_forwardRefrigerant 134a enters a well-insulated nozzle at 200 lbf/in.2, 140°F, with a velocity of 120 ft/s and exits at 90 lbf/in.2 with a velocity of 1500 ft/s.For steady-state operation, and neglecting potential energy effects, determine the temperature, in °F, and the quality of the refrigerant at the exit.arrow_forwardI need some help in how to solve this problem. Any help will be appreciated. Thanksarrow_forward

- Refrigerant 134a enters a well-insulated nozzle at 200 lbf/in.2, 200°F, with a velocity of 120 ft/s and exits at 50 lbf/in.2 with a velocity of 1500 ft/s. For steady-state operation, and neglecting potential energy effects, determine the temperature, in °F, and the quality of the refrigerant at the exit.arrow_forward6.arrow_forwardSteam enters a turbine operating at steady state at 850oF and 450 lbf/in2 and leaves as a saturated vapor at 1.2 lbf/in2. The turbine develops 12,000 hp, and heat transfer from the turbine to the surroundings occurs at a rate of 2 x 106 Btu/h. Neglect kinetic and potential energy changes from inlet to exit. Determine the exit temperature, in oF, and the volumetric flow rate of the steam at the inlet, in ft3/s.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY