Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

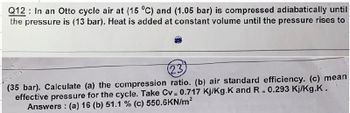

Transcribed Image Text:Q12 In an Otto cycle air at (15 °C) and (1.05 bar) is compressed adiabatically until

the pressure is (13 bar). Heat is added at constant volume until the pressure rises to

23

(35 bar). Calculate (a) the compression ratio. (b) air standard efficiency. (c) mean

effective pressure for the cycle. Take Cv = 0.717 Kj/Kg.K and R = 0.293 Kj/Kg.K.

Answers: (a) 16 (b) 51.1 % (c) 550.6KN/m²

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Similar questions

- In an air standard brayton cycle, air enters the compressor at 27 degree C and 100 kPa. The pressure ratio is 10, and the maximum allowable temperature is 1350 K. the compressor and turbine efficiencies are 85%, and pressure drops 27 kPa between the compressor discharge and turbine inlet. Determine the pressure and temperature at each state in the cycle, the compressor and turbine work, and the cycle thermal efficiency. Please show the PV and TS diagram. Please show complete formulas and solutions.arrow_forwardA cold air-standard Diesel cycle (k =1.4) has a compression ratio of 18.1 and a cutoff ratio of 2.5. The state at the beginning of the compression is fixed at 14.7 psia and T = 85 F. For this cycle determine: %3D (a) sketch a P-V diagram for the cycle and label the data states (b) the maximum pressure (psia) (c) the thermal efficiency (d) the net work (Btu/lbm) NA k**L.4jhas a comoression rall 9. All pdf pdf 24°C IIarrow_forwardThe state at the beginning of compression of an air-standard Diesel cycle is fixed by p₁ = 100 kPa and T₁ = 310 K. The compression ratio is 18 and the cutoff ratio is 1.9. Determine: (a) the maximum temperature, in K. (b) the pressure at the end of the expansion, in kPa. (c) the net work per unit mass of air, in kJ/kg. (d) the percent thermal efficiency.arrow_forward

- At the beginning of the compression process of an air-standard Diesel cycle, p₁ = 95 kPa and T₁ = 300 K. The maximum temperature is 2100 K and the mass of air is 12 g. For a compression ratio of 18, determine: (a) the net work developed, in kJ. (b) the percent thermal efficiency. (c) the mean effective pressure, in kPa.arrow_forwardAir at 100 kPa, 37°C enters an ideal Otto cycle. The peak pressure and temperature in the cycle are 4.6MPa and 1927 °C, respectively. The compression ratio is 6.414. Using an air-standard analysis, determine: a. The internal energy at each part of the cycle: U₁ = U₂ = Uz = U4 = b. the net work per unit mass b. the cycle thermal efficiency= = kJ/kg kJ/kg kJ/kg kJ/kg kJ/kgarrow_forwardAt the beginning of the compression process of an air-standard Otto cycle, p1 = 100 kPa, T1 = 290 K, V1 = 400 cm3. The maximum temperature in the cycle is 2200 K and the compression ratio is 8. Determine the (a) thermal efficiency; and (b) mean effective pressure, in bar. (c) Solve on a cold air-standard basis with constant specific heats.arrow_forward

- Refer to the following figure for an Air Standard Otto Cycle. At the beginning of compression stroke: • Volume is 0.45 m³; • Pressure is 1 bar; and • Temperature is 30°C; At the end of the compression stroke: • Pressure is 11 bar; 210 kJ of heat is added at constant volume. Assuming the cycle is reversible. T(K) = 273 +T(°C); Determine the following to the approximation. • Pressures at point 4 bar • Swept Volume= m • Maximum Temperature of the cycle = °C • Net work output of the cycle = kJ • Heat Rejected from the cycle = kJ • Thermal efficiency of the cycle = • Mean Effective Pressure = bar % p (bar) 21.48 11 V₁ = 0.45 m³ Adiabatics → V (m³)arrow_forwardAir enters the compressor of an ideal air-standard Brayton cycle at 88 kPa, 280 K, with a volumetric flow rate of 1225 m3/s. The compressor pressure ratio is 12. The turbine inlet temperature is 1225 K. Take Specific heat at constant pressure and constant volume for air as 1.006 kJ/kg K and 0.717 kJ/kg K respectively. Calculate the thermal efficiency of the plant to one decimal place and include the correct unit (percentage). Use cold air standard assumptionarrow_forward3The rate of heat addition to an ideal air-standard Brayton cycle is 1.0 x 107 Btu/h. The pressure ratio for the cycle is 12 and the minimum and maximum temperatures are 520°R and 2800°R, respectively.Determine:(a) the percent thermal efficiency of the cycle.(b) the mass flow rate of air, in lb/h.(c) the net power developed by the cycle, in hp.arrow_forward

- In an Otto cycle air at 27 degree centigrade and 1 bar is compressed adiabatically to 12bar. Heat addition occurs at constant volume and pressure rises to 30bar. Determine the air standard efficiency, compression ratio. Assume Cv= 0.717 KJ/kgK for air.arrow_forwardAir enters the compressor of an ideal air-standard Brayton cycle at 100 kPa, 283 K, with a volumetric flow rate of 5 m3/s. The compressor pressure ratio is 8:1. The turbine inlet temperature is 1400 K. Take Specific heat at constant pressure and constant volume for air as 1.006 kJ/kg K and 0.717 kJ/kg K respectively. Calculate the compressor exit absolute temperature to one decimal place and place the correct unit. Use the cold air-standard assumption.arrow_forwardRequired information Problem 09.015 - 3-Step Air-Standard Cycle with Constant Specific Heats - DEPENDENT MULTI-PART PROBLEM - ASSIGN ALL PARTS An air-standard cycle with constant specific heats at room temperature is executed in a closed system with 0.003 kg of air and consists of the following three processes: 1-2 v= Constant heat addition from 95 kPa and 17°C to 380 kPa 2-3 Isentropic expansion to 95 kPa 3-1 P = Constant heat rejection to initial state The properties of air at room temperature are cp = 1.005 kJ/kg-K, cy= 0.718 kJ/kg-K, and k = 1.4. Problem 09.015.b - Net Work for Constant Heat Capacity Air-Standard Cycle Calculate the net work per cycle, in kJ. (You must provide an answer before moving on to the next part.) The net work per cycle is kJ.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY